Nanometer hybrid material integrating positive/negative cyclic effects and preparation method thereof

A nano-hybrid material and effect technology, applied in the field of materials, can solve the problems of silicon/carbon nanocomposite material capacity decline, limited silicon application, and shortened battery cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

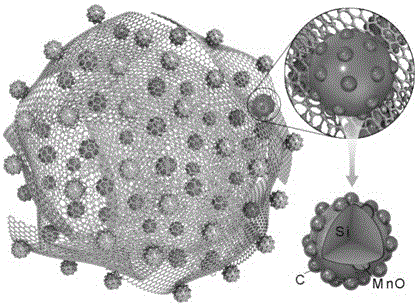

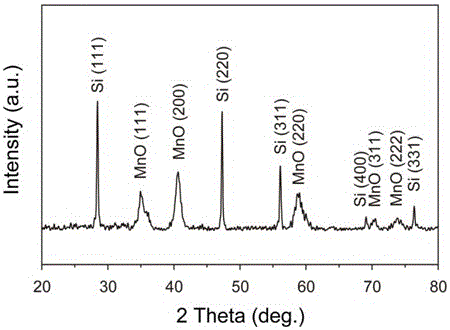

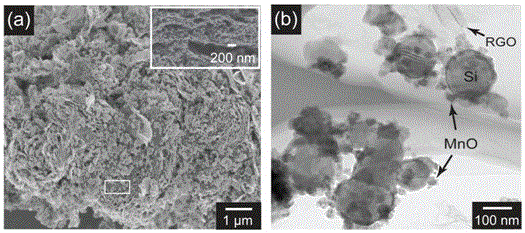

[0026] Preparation of (Si@MnO)@C / RGO Nano-hybrid Materials

[0027] Under the condition of magnetic stirring, the manganese chloride of 0.49 g, the sodium oleate of 1.52 g are successively added in the mixed solution of 8 ml water, 14 ml ethanol and 50 ml n-hexane, after stirring at room temperature for 4 hours, the mixed solution is layered, The upper layer solution becomes a light brown manganese oleate / n-hexane solution, and the lower layer is an aqueous solution of sodium chloride. The manganese oleate / n-hexane solution in the upper layer can be separated by repeated washing with 50 ml of deionized water through a separatory funnel. Then 60 mg of silicon nanoparticles were added to the manganese oleate / n-hexane solution, and after stirring for 4 hours, 18 mg of graphene nanosheets were added, stirred for 4 hours again, and then stirred at 70 o C rotary evaporation to obtain the precursor. Finally, under the condition of high-purity nitrogen atmosphere, the precursor was ...

Embodiment 2

[0029] Preparation of (Si@MnO)@C / RGO Nano-hybrid Materials

[0030] Under the condition of magnetic stirring, the manganese chloride of 0.49 g, the sodium oleate of 1.52 g are successively added in the mixed solution of 8 ml water, 14 ml ethanol and 50 ml n-hexane, after stirring at room temperature for 4 hours, the mixed solution is layered, The upper layer solution becomes a light brown manganese oleate / n-hexane solution, and the lower layer is an aqueous solution of sodium chloride. The manganese oleate / n-hexane solution in the upper layer can be separated by repeated washing with 50 ml of deionized water through a separatory funnel. Then 40 mg of silicon nanoparticles were added to manganese oleate / n-hexane solution, and after stirring for 4 hours, 18 mg of graphene nanosheets were added, stirred for 4 hours again, and then stirred at 70 o C rotary evaporation to obtain the precursor. Finally, under the condition of high-purity nitrogen atmosphere, the precursor was prep...

Embodiment 3

[0032] Preparation of (Si@MnO)@C / RGO Nano-hybrid Materials

[0033] Under the condition of magnetic stirring, the manganese chloride of 0.49 g, the sodium oleate of 1.52 g are successively added in the mixed solution of 8 ml water, 14 ml ethanol and 50 ml n-hexane, after stirring at room temperature for 4 hours, the mixed solution is layered, The upper layer solution becomes a light brown manganese oleate / n-hexane solution, and the lower layer is an aqueous solution of sodium chloride. The manganese oleate / n-hexane solution in the upper layer can be separated by repeated washing with 50 ml of deionized water through a separatory funnel. Then 20 mg of silicon nanoparticles were added to the manganese oleate / n-hexane solution, and after stirring for 4 hours, 20 mg of graphene nanosheets were added, stirred for 4 hours again, and then stirred at 70 o C rotary evaporation to obtain the precursor. Finally, under the condition of high-purity nitrogen atmosphere, the precursor was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com