PID parameter optimization method for permanent magnet synchronous motor control system

A permanent magnet synchronous motor and control system technology, applied in the control system, vector control system, motor generator control, etc., can solve the problems of increasing the research and development cost of the control system, long debugging time, and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

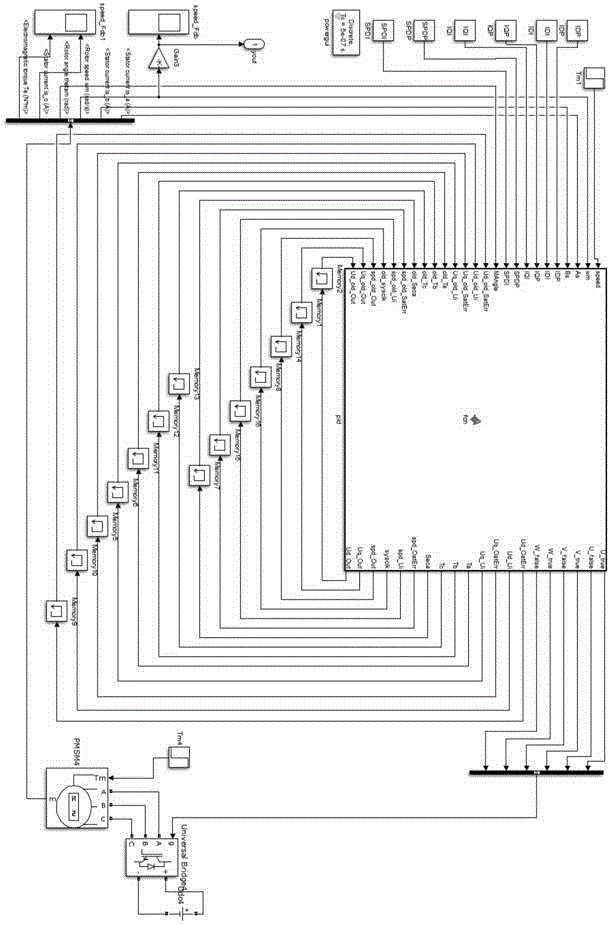

[0087] Specific embodiment 1: combine Figure 1-Figure 8 , a PID parameter optimization method for a permanent magnet synchronous motor control system; comprising the following steps:

[0088] Step 1: According to the inner loop current loop control period T of the actual control system C , Outer loop speed loop control period T S , Crystal frequency f osc , crystal period T s , calculate the simulation step size T of the simulation system 1 , current loop period T C1 and the velocity loop period T S1 ;

[0089] Step 2: according to permanent magnet synchronous motor rated current, rated speed, carry out normalized calculation;

[0090] Step 3: CLARK transformation;

[0091] Step 4: PARK transformation;

[0092] Step 5: IPARK transformation;

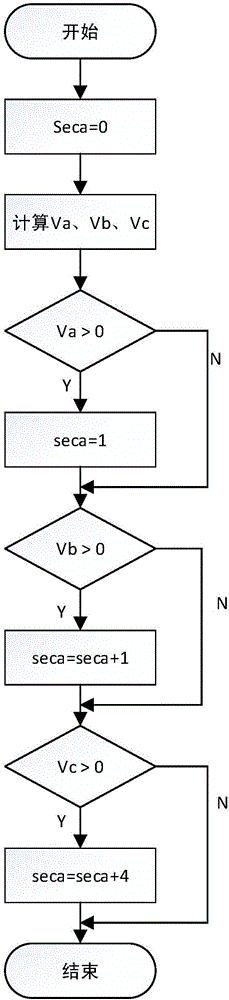

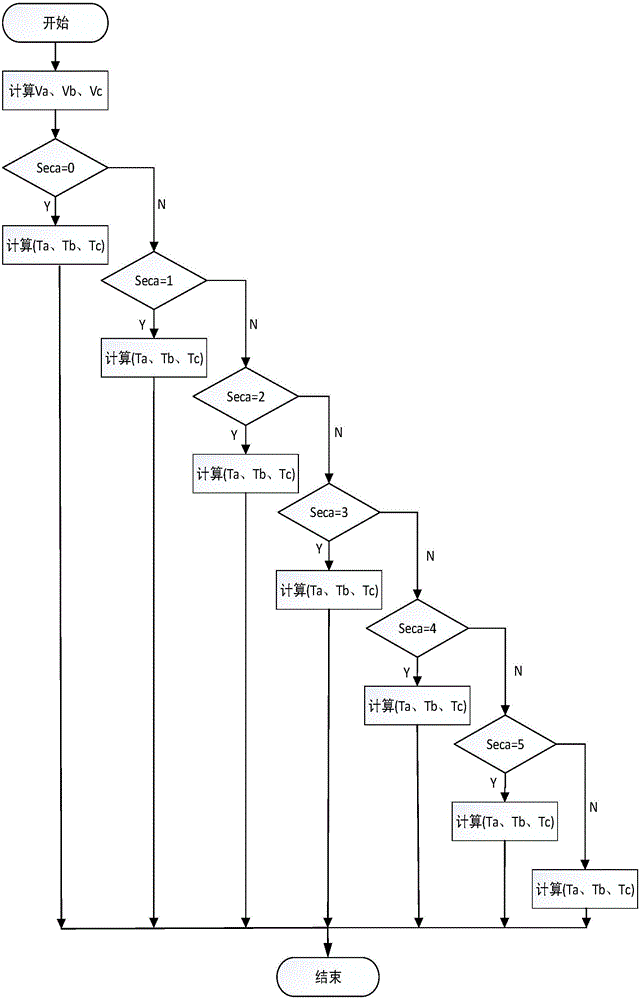

[0093] Step 6: SVPWM design;

[0094] Step 7: PID parameter discretization process;

[0095] Step 8: set up control system parameter evaluation function;

[0096] Step 9: genetic algorithm design;

[0097] Step 10: configur...

specific Embodiment 2

[0165] Specific embodiment 2: Specific embodiment 2: the present invention is based on a kind of permanent magnet synchronous motor control system PID parameter optimization method, the user can set the device in the simulation environment according to the motor of the control system of oneself, the inverter, according to the control program of oneself related configuration in the simulation system, set the relevant configuration options in the simulation system, and modify the relevant parameter range at the same time, then you can use the present invention to adjust and optimize the control parameters, and finally apply the parameter configuration in the simulation environment to your actual in the control system.

[0166] The configuration and settings of the simulation environment are as follows: Windows 10x64 operating system; Intel(R) Core(TM) i5-3230M processor; 8G memory; the simulation software uses Matlab8.5 of MathWorks Company, including the Simulink module.

[016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com