Method for preparing O-carboxymethyl chitosan covered nano-silver

A technology of carboxymethyl chitosan and nano-silver, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of nano-silver easy to agglomerate, poor dispersion, and human health hazards. Achieve good dispersibility and stability, easy operation, and healthy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

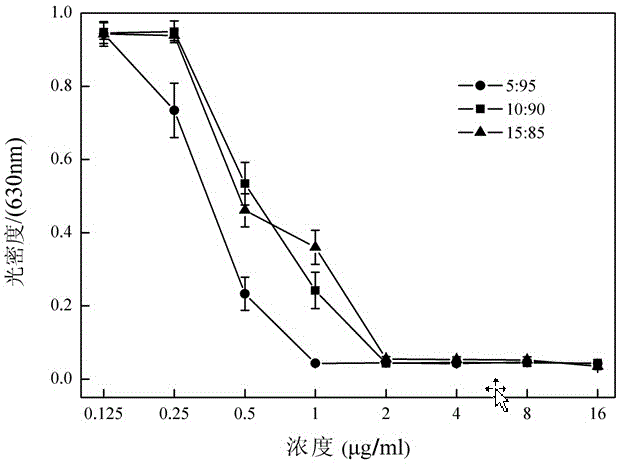

[0029] (1) 0.1g silver nitrate was dissolved in 100ml ultrapure water, 0.1g O-carboxymethyl chitosan was dissolved in 100ml ultrapure water, mixed at a volume ratio of 5:95, and magnetically stirred for 0.5h;

[0030] (2) Take 3mL of the mixed solution and put it in a 4mL quartz cuvette, ventilate nitrogen for 20s to exhaust the air and then seal it, place the sample bottle at a distance of 5cm from a 272nm UV lamp and irradiate it for 130min with the power of the UV lamp at 20w;

[0031] (3) After the ultraviolet lamp irradiation, the mixed solution in the quartz cuvette turned golden yellow, and one volume of absolute ethanol was added to the mixed solution, and the precipitate was centrifuged at 14000r / min for 60min, and the two cuvettes were centrifugally washed with 50%wt ethanol. Second-rate;

[0032] (5) Freeze-dry the precipitate to obtain O-carboxymethyl chitosan-coated nano-silver composite antibacterial agent powder.

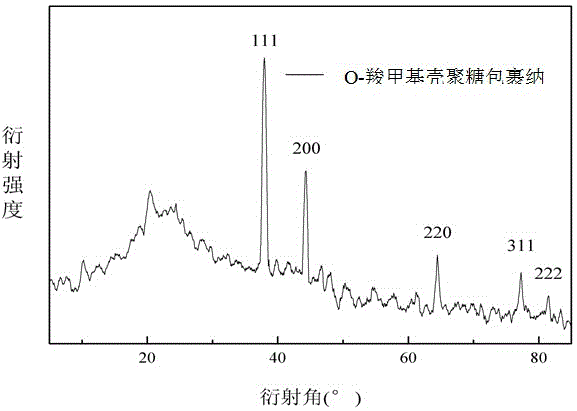

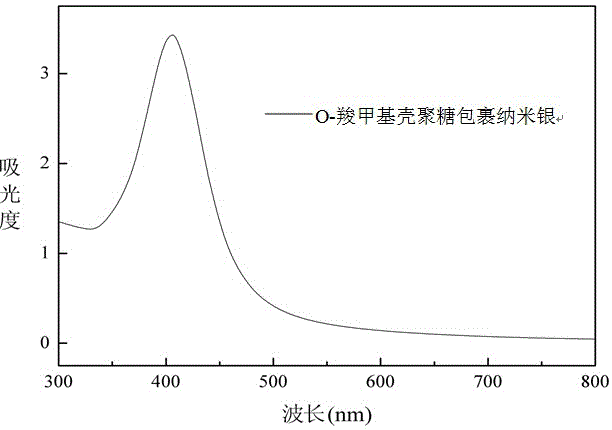

[0033] (6) O-carboxymethyl chitosan-coated nan...

Embodiment 2

[0040] According to the processing method of embodiment 1, the difference of embodiment 2 is: the ultraviolet irradiation time is 70min. After ultraviolet irradiation, the mixed solution was light yellow, and the ultraviolet absorption peak of nano silver was lower than that of Example 1 in the ultraviolet-visible light spectrum test. Compared with Example 1, Example 2 reduces the UV irradiation time to obtain nano-silver with smaller size, more stability and lighter color, which is beneficial for further application, but the yield of nano-silver is not high, resulting in an increase in cost.

Embodiment 3

[0042] According to the process of Example 1, the difference of Example 4 is that the container used for ultraviolet irradiation is a glass sample bottle. Glassware is cheaper and easier to obtain than quartz vessels, which can effectively reduce the cost, but the light transmittance of quartz cuvettes is higher than that of glass bottles. Under the same irradiation time, the UV absorption peak of the sample using glass sample bottles in this embodiment is far lower than that in the embodiment. 1. The yield of nano-silver is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com