Mass production device and mass production method of a chalcogen compound

A technology of chalcogen compounds and chalcogen elements, applied in the direction of binary selenium/tellurium compounds, tin compounds, chemical instruments and methods, etc., can solve problems such as evaporation and loss of highly volatile chalcogen elements, environmental threats, safety accidents, etc. To achieve the effect of maintaining consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

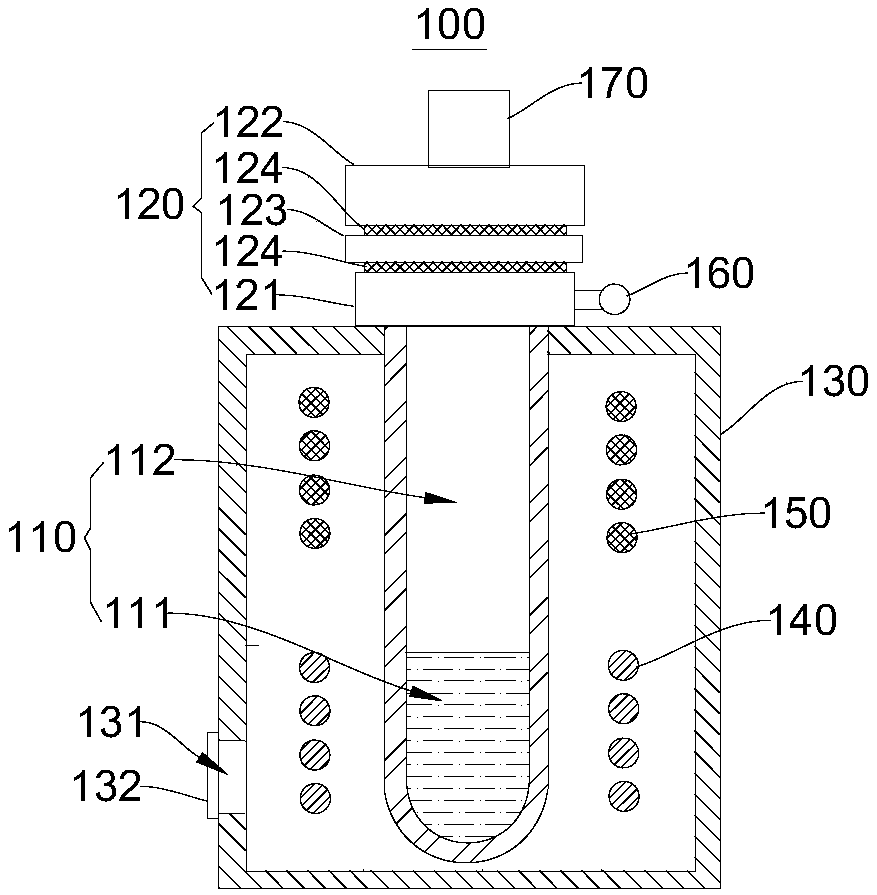

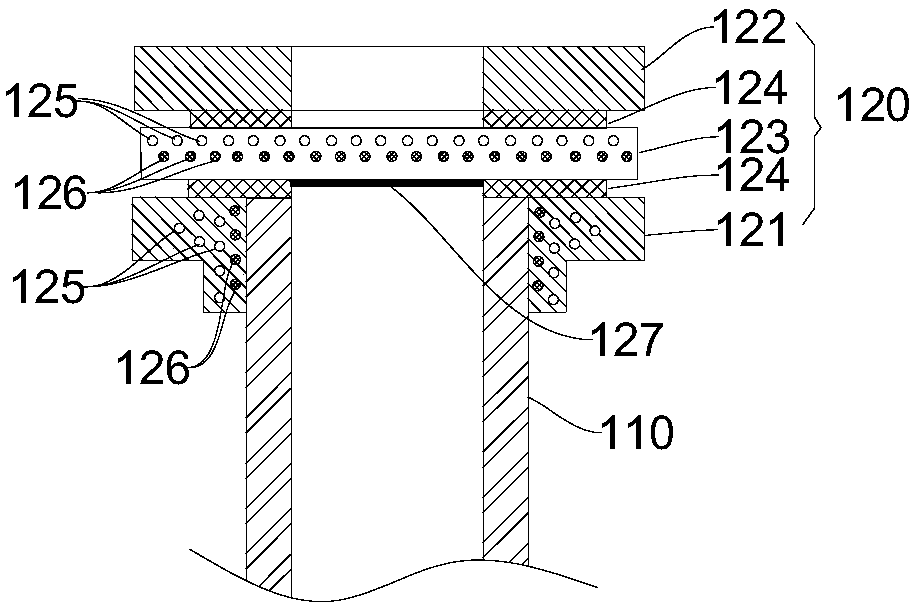

[0064] Example 1: CuSe 2 Compound preparation

[0065] The copper (Cu) and selenium (Se) pellets with a total weight of 4 kg and a purity >= 4N are in the atomic ratio Cu:Se=1:2, or the corresponding weight ratio Cu:Se=1:0.4, That is, 1.14Kg of copper and 2.86Kg of selenium are put into the quartz container 110, and the first flange 121, the second flange 122 and the nickel alloy gasket 124 are locked with screws. Start the vacuum pump to evacuate the system. When the vacuum reaches 5x10 -4 When Pa, close the VAT valve. The quartz vessel 110, the first flange 121 and the VAT valve form a sealed vacuum reaction space. In this embodiment, the thickness of the quartz container 110 is 4 mm, the ratio of the inner diameter to the length is 1:3, and the area ratio of the inner surfaces of the second part 112 and the first part 111 of the quartz container 110 is 2:1.

[0066] During the main reaction period: the first heating component 140 is controlled to raise the temperature ...

Embodiment 2

[0070] Example 2: As 2 Se 3 Compound preparation

[0071] Arsenic (As) and selenium (Se) small particles with a total weight of 2Kg and a purity of >=4N are according to the atomic ratio As:Se=2:3, or the corresponding weight ratio is the ratio of As:Se=0.63:1, namely , arsenic 0.77Kg, selenium 1.23Kg, put into the quartz container 110, and then the first flange 121, the second flange 122 and the nickel alloy gasket 124 are locked with screws. Evacuate the reaction vessel to a vacuum of 3x10 -4 Pa, and then close the VAT valve. The quartz vessel 110, the first flange 121 and the VAT valve form a sealed vacuum reaction space. In this embodiment, the thickness of the quartz container 110 is 6 mm, the ratio of the inner diameter to the length is 1:4, and the area ratio of the inner surfaces of the second part 112 and the first part 111 of the quartz container 110 is 2.5:1.

[0072] The process enters the main reaction period: the first temperature is controlled to rise at a ...

Embodiment 3

[0075] Embodiment 3: copper zinc tin sulfur CZTS (Cu 2 ZnSnS 4 ) Preparation of quaternary compounds

[0076] Quaternary alloy copper-zinc-tin-sulfur (CZTS), as a new generation of surface solar cell materials, has begun to attract the attention of the photovoltaic industry, especially its raw materials are abundant in the earth and the cost is very low. But its disadvantage is that when the quaternary compound is formed, the reaction is very violent, and because it contains highly volatile sulfur, it is difficult to control the atomic ratio between its elements. The molecular formula of copper zinc tin sulfur used in thin film photovoltaic materials is usually: Cu 2 ZnSnS 4 , the ideal atomic ratio is: Cu:Zn:Sn:S=2:1:1:4, and the corresponding weight percentages are: Cu29.04%, Zn14.53%, Sn27.13%, S29.30%. Put the copper, zinc, tin, and sulfur pellets with a total weight of 2Kg and a purity higher than 4N into the reaction vessel according to the weight: 0.58Kg of copper, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com