Method of utilizing biochar for adsorbing orange II dye waste water and catalytically degrading the orange II dye waste water with persulfate

A dye wastewater, persulfate technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, physical/chemical process catalysts, etc., can solve problems such as less biochar, and achieve enhanced removal effect, low cost, and abundant sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method for utilizing biochar to adsorb and catalyze persulfate to degrade orange II dye wastewater comprises the following steps:

[0019] a) prepare biochar modified by hydrofluoric acid:

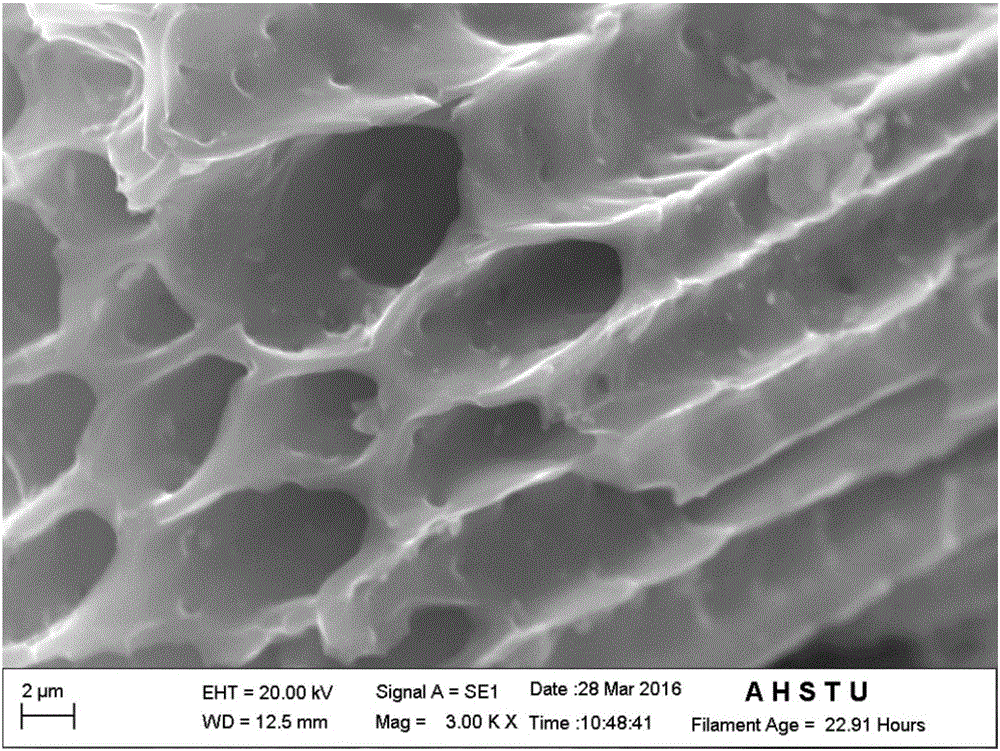

[0020] Add rice husk to a concentration of 0.2mol.L -1 In the hydrofluoric acid solution, the mass ratio of rice husk to hydrofluoric acid solution was 1:20, mixed and stirred for 12 hours, filtered, washed with distilled water to neutrality, and dried at 60°C to obtain modified biomass, modified rice husk biomass The substance is pyrolyzed at 300°C in a biochar preparation device (the application number is a biochar pyrolysis device disclosed in 201310082211.X) to obtain biochar;

[0021] b) Process of degrading orange II dye wastewater:

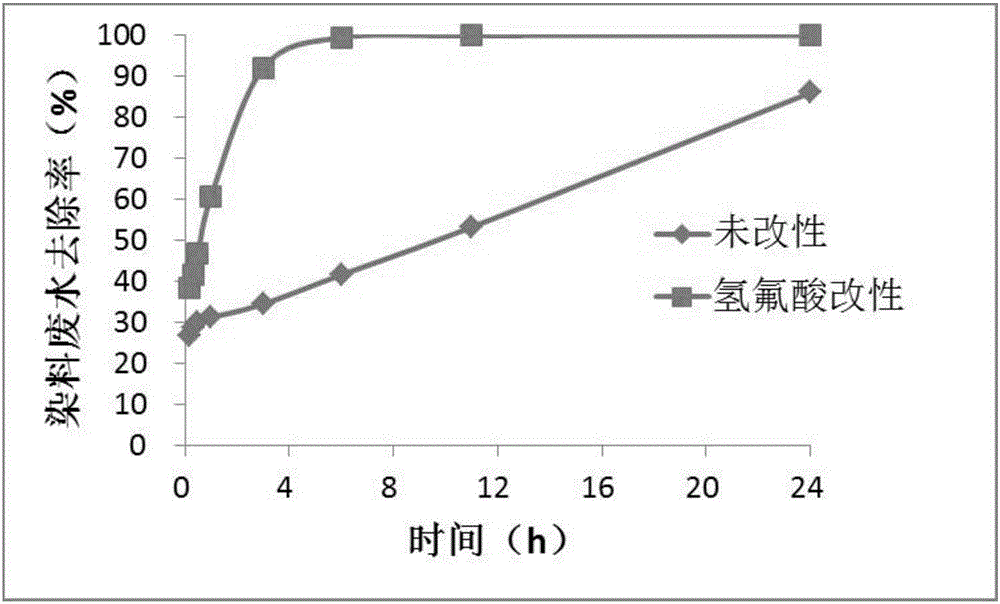

[0022] Mix persulfate with orange II dye wastewater, the molar ratio of persulfate and orange II dye wastewater is 20:1, add biochar into the mixed solution, the mass concentration of biochar is 10g.L -1 , so that the pH of the mixed solut...

Embodiment 2

[0025] The method for utilizing biochar to adsorb and catalyze persulfate to degrade orange II dye wastewater comprises the following steps:

[0026] a) prepare biochar modified by hydrofluoric acid:

[0027] Add rice husk to a concentration of 2mol.L -1 In the hydrofluoric acid solution, the mass ratio of rice husk to hydrofluoric acid solution is 1:200, mixed and stirred for 24 hours, filtered, washed with distilled water until neutral, and dried at 80°C to obtain modified biomass, modified rice husk biomass The substance is pyrolyzed at 500°C in a biochar preparation device (the application number is: a biochar pyrolysis device disclosed in 201310082211.X) to obtain biochar;

[0028] b) Process of degrading orange II dye wastewater:

[0029] Mix persulfate with orange II dye wastewater, the molar ratio of persulfate and orange II dye wastewater is 100:1, add biochar into the mixed solution, the mass concentration of biochar is 1g.L -1 , the pH of the mixed solution was 1...

Embodiment 3

[0033] The method for utilizing biochar to adsorb and catalyze persulfate to degrade orange II dye wastewater comprises the following steps:

[0034] a) prepare biochar modified by hydrofluoric acid:

[0035] Add rice husk to a concentration of 1mol.L -1 In the hydrofluoric acid solution, the mass ratio of rice husk to hydrofluoric acid solution was 1:100, mixed and stirred for 18 hours, filtered, washed with distilled water until neutral, and dried at 70°C to obtain modified biomass, modified rice husk biomass The substance is pyrolyzed at 400°C in a biochar preparation device (the application number is: a biochar pyrolysis device disclosed in 201310082211.X) to obtain biochar;

[0036] b) Process of degrading orange II dye wastewater:

[0037] Mix persulfate with orange II dye wastewater, the molar ratio of persulfate and orange II dye wastewater is 60:1, add biochar to the mixed solution, the mass concentration of biochar is 5g.L -1 , so that the pH of the mixed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com