Method and system for recycling iron from red mud

A technology for recovering iron and red mud, which is applied in chemical instruments and methods, cement production, process efficiency improvement, etc., can solve the problems of low dealkalization rate, high sulfur content, high energy consumption, etc., and achieve the solution of excessive sulfur content, The effect of low alkali content and high grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

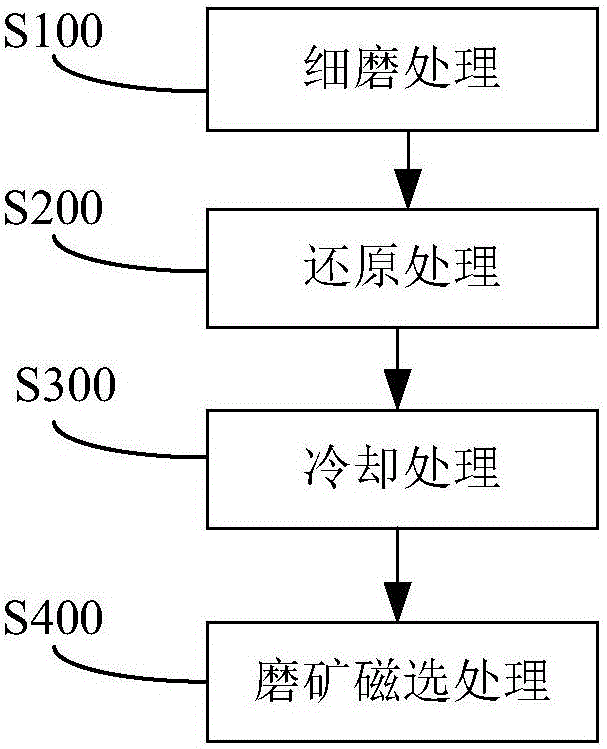

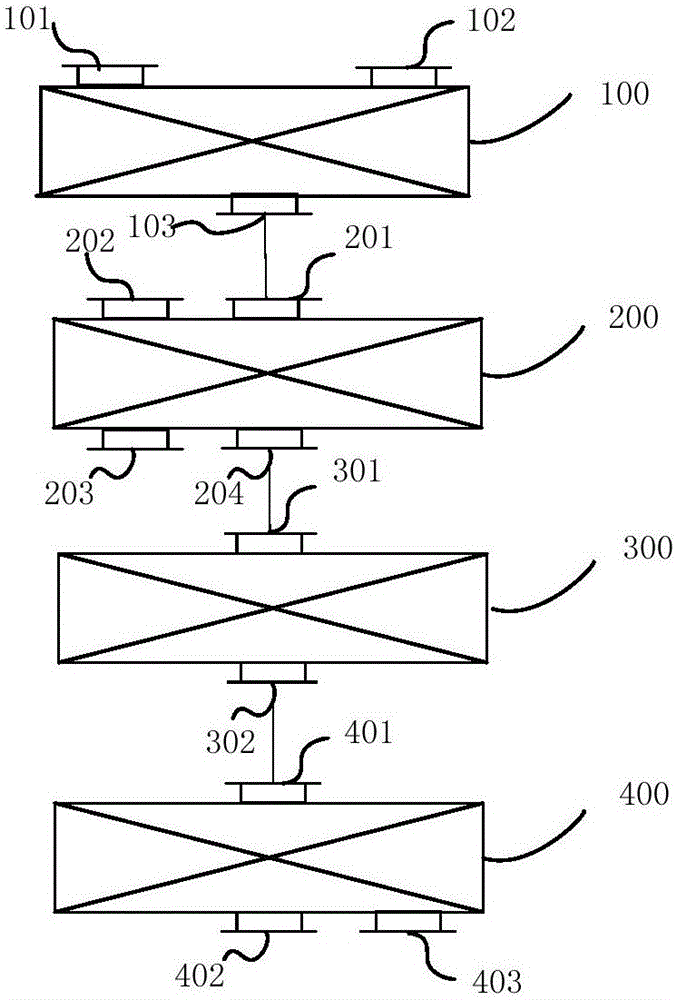

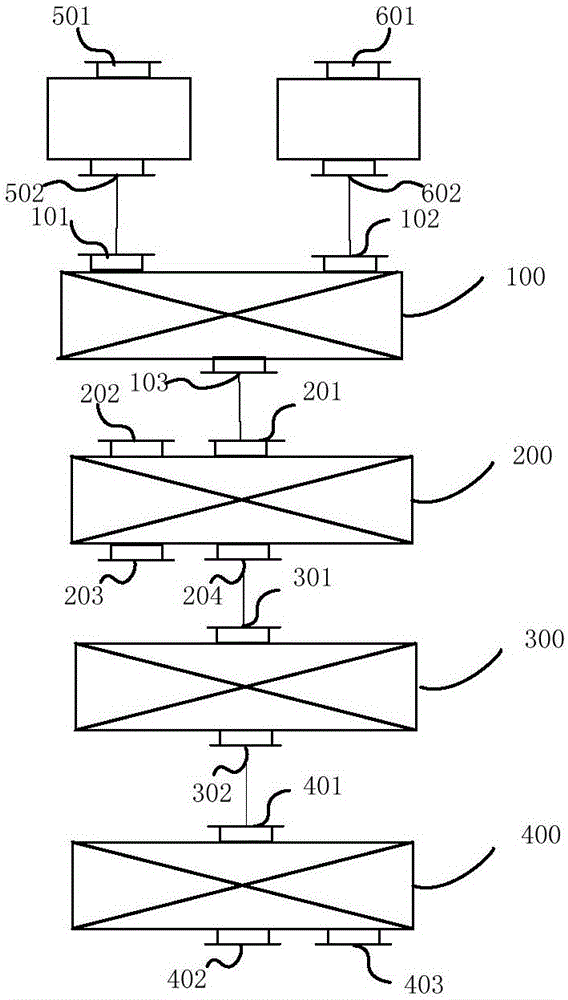

[0066] Utilize the method of the embodiment of the present invention, use pulverized coal as reducing agent, recover iron from red mud, concrete steps are as follows:

[0067] (1) Finely grind the red mud and the reducing agent to -0.043mm, accounting for 85%. With the red mud as 100 parts by weight, add 25% of the reducing agent, and re-grind the material, and the required grinding particle size is -0.043mm mm accounts for 90%.

[0068] (2) Place the mixed powder obtained in step (1) in a tubular roaster for reduction. The initial temperature in the reduction furnace is 800°C. After two hours, the temperature rises to 1100°C. The furnace is fed with CO and N2 A reducing gas in which the CO concentration is 50%. After 3 hours of heat preservation, the reduction powder was taken out.

[0069] (3) The reduced powder is subjected to indirect water cooling.

[0070] (4) Carry out grinding and magnetic separation to the reduction powder after step (3) water cooling, and the grin...

Embodiment 2

[0072] Utilize the method of the embodiment of the present invention, use pulverized coal as reducing agent, recover iron from red mud, concrete steps are as follows:

[0073] (1) Finely grind the red mud and the reducing agent to -0.043mm, accounting for 90%. With the red mud as 100 parts by weight, add 25% of the reducing agent, and re-grind the material, and the required grinding particle size is -0.043mm mm accounts for 95%.

[0074] (2) Place the mixed powder obtained in step (1) in a tubular roaster for reduction. The initial temperature in the reduction furnace is 800°C. After two hours, the temperature rises to 1150°C. 2 A reducing gas in which the CO concentration is 50%. After 3 hours of heat preservation, the reduction powder was taken out.

[0075] (3) The reduced powder is subjected to indirect water cooling.

[0076] (4) The water-cooled reduced powder in step (3) was subjected to grinding and magnetic separation, and the grinding time was 5 minutes to obtain ...

Embodiment 3

[0078] Utilize the method of the embodiment of the present invention, use pulverized coal as reducing agent, recover iron from red mud, concrete steps are as follows:

[0079] (1) Finely grind the red mud and the reducing agent to -0.043mm, accounting for 90%. With the red mud as 100 parts by weight, add 25% of the reducing agent, and re-grind the material, and the required grinding particle size is -0.043mm mm accounts for 95%.

[0080] (2) Place the mixed powder obtained in step (1) in a tubular roaster for reduction. The initial temperature in the reduction furnace is 800°C. After two hours, the temperature rises to 1150°C. 2 The reducing gas, in which the CO concentration is 30%. After 3 hours of heat preservation, the reduction powder was taken out.

[0081] (3) The reduced powder is subjected to indirect water cooling.

[0082] (4) The water-cooled reduced powder in step (3) was subjected to grinding and magnetic separation, and the grinding time was 5 minutes to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com