Superbacteria antibiotic disinfectant, preparation method and purpose thereof

A technology of disinfectant and antibacterial material, applied in the field of super bacteria antibacterial disinfectant and its preparation, can solve the problems of human skin allergy, prone to burning accidents, and decreased sterilization performance, and achieve the effect of strong sterilization effect and good sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

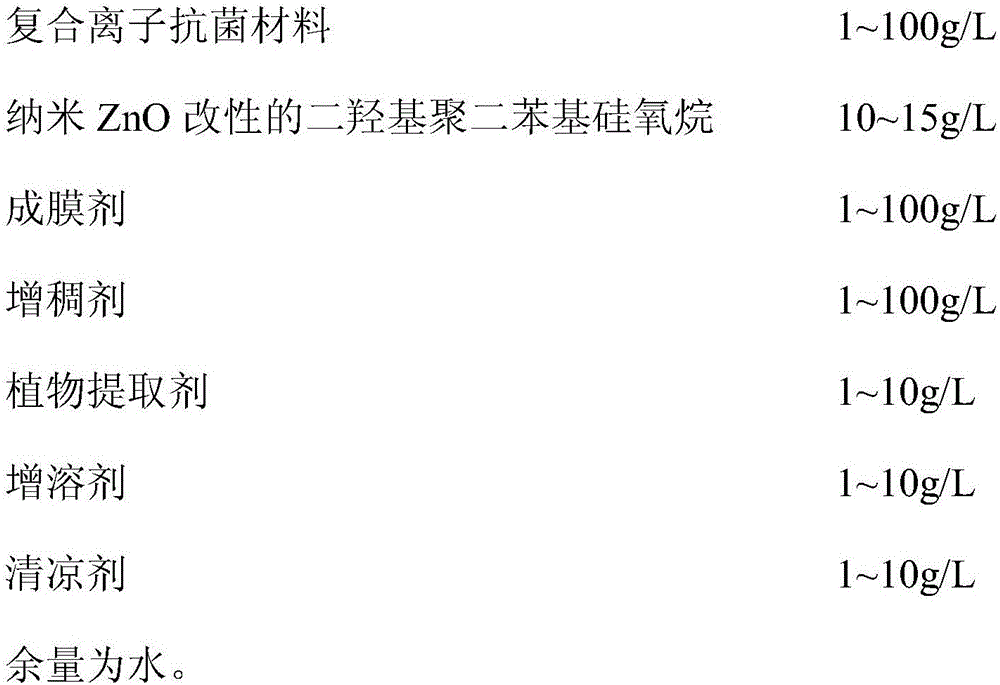

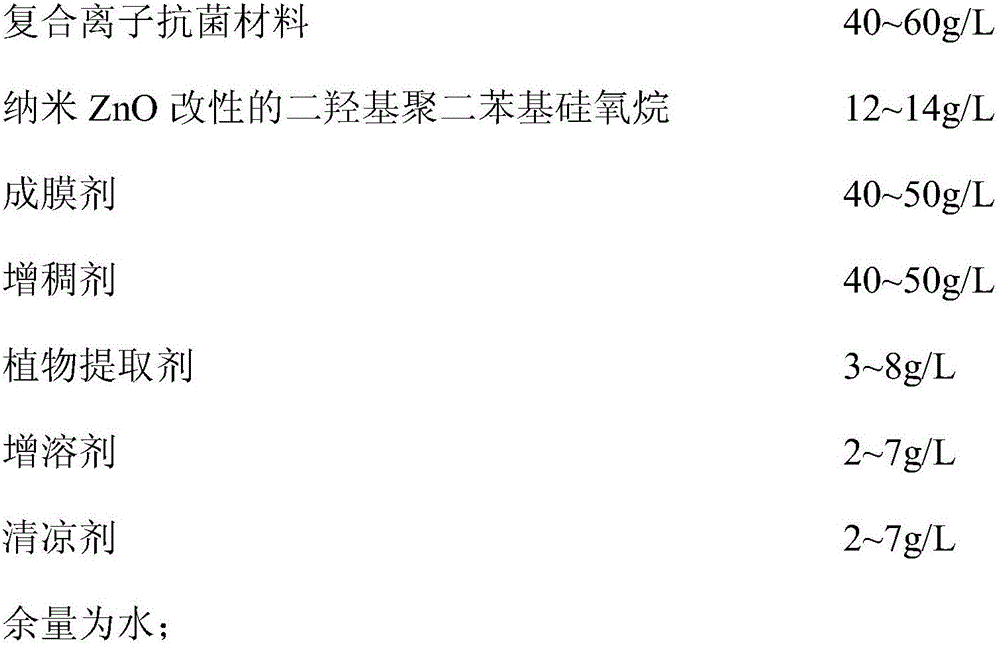

Method used

Image

Examples

Embodiment 1

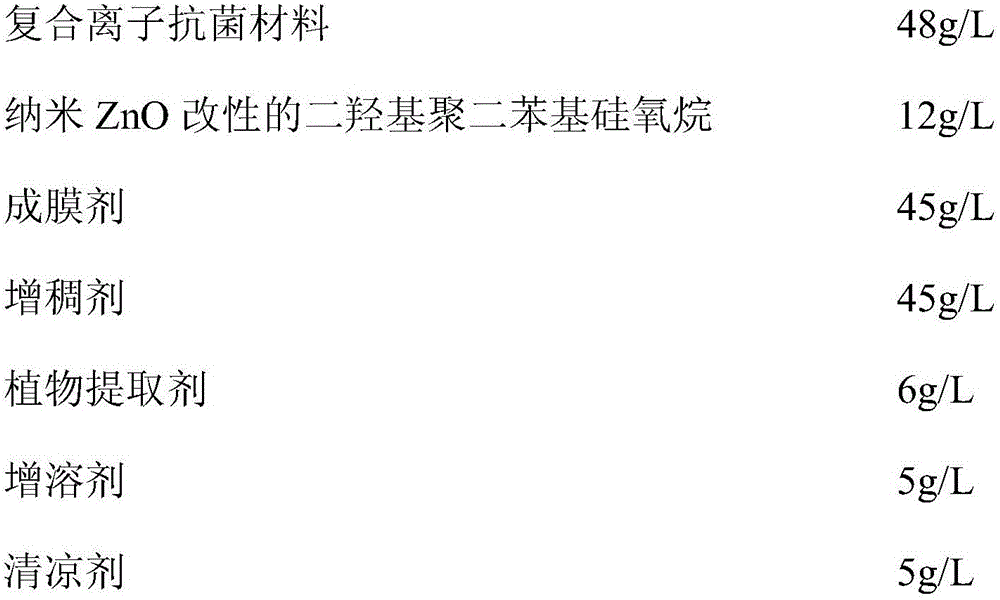

[0047] The present embodiment provides an antibacterial disinfectant, containing the following components in every liter of antibacterial disinfectant: 48g of composite ionic antibacterial material, 12g of dihydroxy polydiphenylsiloxane modified by nano ZnO, film forming agent 2,2 , 4-trimethyl-1,3-pentanediol monoisobutyrate 45g, thickener sodium carboxymethylcellulose 45g, plant extractant grape seed extract 6g, solubilizer polyoxyethylene hardened castor oil 5g and cooling agent menthyl lactate 5g, and the balance is purified water.

[0048] Among them, the composite ionic antibacterial material is prepared by intercalation assembly of quaternary ammonium ionic liquid and inorganic nano-layer compound α-zirconium hydrogen phosphate, and the molar ratio of quaternary ammonium ionic liquid and inorganic nano-layer compound α-zirconium hydrogen phosphate is 1:3.

Embodiment 2

[0050] The present embodiment provides a kind of antibacterial disinfectant, contains the following components in every liter of antibacterial disinfectant: composite ionic antibacterial material 20g, nano ZnO modified dihydroxy polydiphenylsiloxane 13g, film-forming agent propylene glycol butyl ether 3g, thickener propylene glycol alginate 6g, plant extractant cherry extract 3g, solubilizer fatty alcohol polyoxyethylene ether 2g, cooling agent menthyl lactate 2g and essence 6g, and the balance is purified water.

[0051] Among them, the composite ionic antibacterial material is prepared by intercalation assembly of quaternary ammonium ionic liquid and inorganic nano-layer compound α-zirconium hydrogen phosphate, and the molar ratio of quaternary ammonium ionic liquid and inorganic nano-layer compound α-zirconium hydrogen phosphate is 1:2.

Embodiment 3

[0053] The present embodiment provides a kind of antibacterial disinfectant, contains the following components in every liter of antibacterial disinfectant: composite ionic antibacterial material 40g, nano ZnO modified dihydroxy polydiphenylsiloxane 14g, film forming agent polyvinyl alcohol 50g, thickener carbomer 20g, plant extractant cherry extract 4g, solubilizer polyoxyethylene hardened castor oil 3g, cooling agent menthyl lactate 3g and essence 3g, and the balance is purified water.

[0054] Among them, the composite ionic antibacterial material is prepared by intercalation assembly of quaternary phosphorus ionic liquid and inorganic nano-layer compound α-zirconium hydrogen phosphate, and the molar ratio of quaternary phosphorus ionic liquid and inorganic nano-layer compound α-zirconium hydrogen phosphate is 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com