Heat insulation sunshade pad for automobile

A technology for sunshade pads and automobiles, which is applied to vehicle parts, heat exchange materials, coatings, etc., can solve the problems of high body temperature and poor heat insulation effect of heat insulation sunshade pads, and achieves improved mechanical strength and significant heat insulation. performance, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

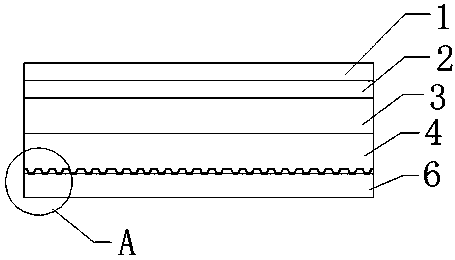

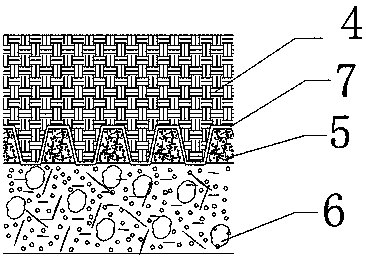

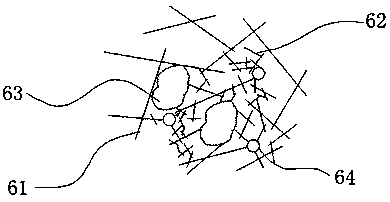

[0036] Such as figure 1 and figure 2 As shown, a heat-insulating sunshade pad for automobiles is sequentially bonded with a metal reflective film 2, a tear-resistant layer 3, a glass wool structural layer 4 and a flexible heat-conducting layer 6 from top to bottom, and the metal reflective film 2 is far away from the tear-resistant One side of layer 3 is evenly coated with fluorocarbon varnish 1, the tear-resistant layer 3 is woven with high-strength yarn, and the side of the glass wool structure layer 4 bonded with the flexible heat-conducting layer 6 is provided with several cone bases, inside the cone base Filled with phase change material 5 , the flexible heat conduction layer 6 is bonded to the glass wool structural layer through an adhesive coating 7 .

[0037] Glass wool structure layer 4, glass wool has good heat insulation effect, but also has good toughness and stability. When it is used for heat insulation sunshade pad, it can play a good heat insulation effect on...

Embodiment 2

[0079] The second embodiment is the same as the first embodiment, except that the solid-liquid phase change material is composed of the following by mass percentage: expanded graphite 9%, binary eutectic fatty acid 82%, porous magnesium oxide 1%, porous poly 5% ester fiber, 3% carboxymethyl cellulose, in which the binary deep eutectic fatty acid is blended from lauric acid and myristic acid.

Embodiment 3

[0081] Embodiment three is the same as embodiment one and embodiment two, and the difference is that the solid-liquid phase change material is composed of the following by mass percentage: expanded graphite 7%, binary eutectic fatty acid 83%, porous magnesium oxide 5% %, porous polyester fiber 3%, carboxymethyl cellulose 2%, of which the binary eutectic fatty acid is blended from lauric acid and myristic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com