Ultra-loose graphitized structure porous carbon nanofiber and electrostatic spinning-carbonizing preparation method thereof

A nanofiber and electrospinning technology, which is applied to structural parts, circuits, electrical components, etc., can solve the problems of no carbon nanofiber preparation method, and achieve the effect of simple preparation method, easy reaction conditions and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

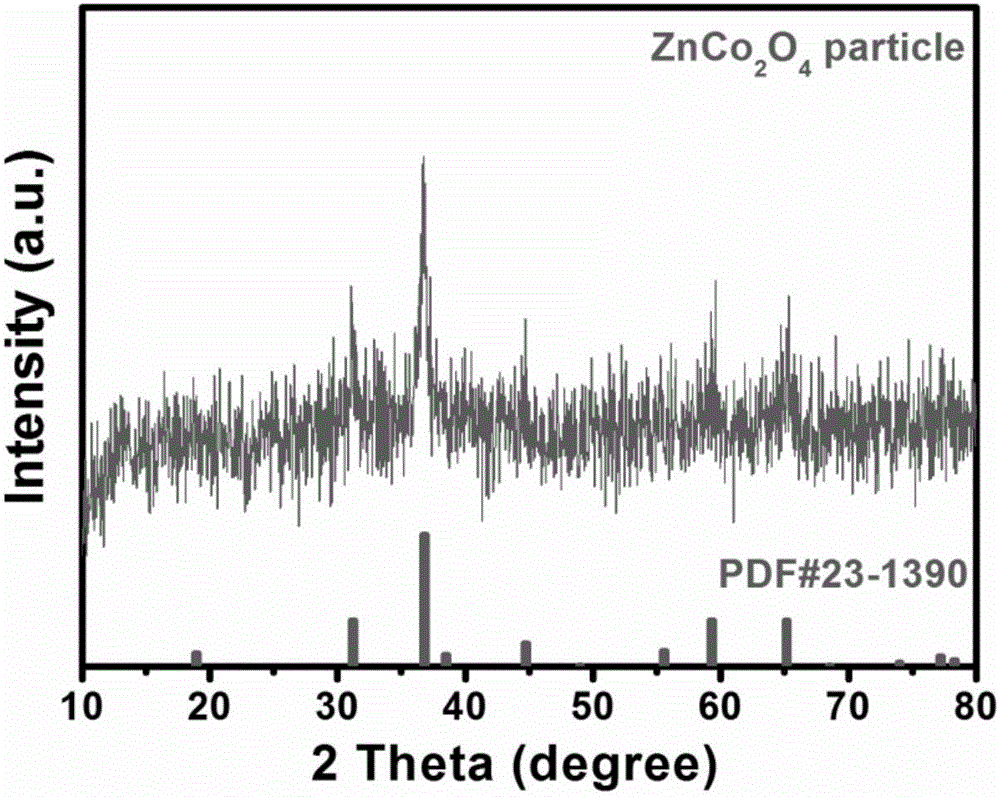

[0032] Weigh 1.5g of zinc nitrate, 6g of cobalt nitrate, and 1g of urea with an electronic balance, dissolve them in distilled water, react at 110°C for 12 hours, filter and wash with distilled water, and dry at 50°C for 8 hours to obtain ZnCo 2 o 4 precursor, then annealed at 400°C, and ball milled for 3 hours to obtain ZnCo 2 o 4 particles. ZnCo 2 o 4 The XRD image of the particles is shown in figure 1 .

[0033] Weighing ZnCo Accurately with Analytical Balance 2 o 4 and polyacrylonitrile (PAN) powder (where ZnCo 2 o 4 , PAN mass ratio 0.5:2, and the molar mass M of PAN=100000g / mol, mass fraction is 8%) is placed in 20ml sample bottle, utilizes pipette to accurately pipette 10ml of N-N dimethylformamide (DMF) , the sample bottle was sealed with raw material tape, heated to 50 °C, stirred for 36 hours, and finally ZnCo 2 o 4 / PAN uniformly dispersed electrospinning solution.

[0034] Electrospinning equipment was used to prepare nanofibers, and carbonized at 850°...

Embodiment 2

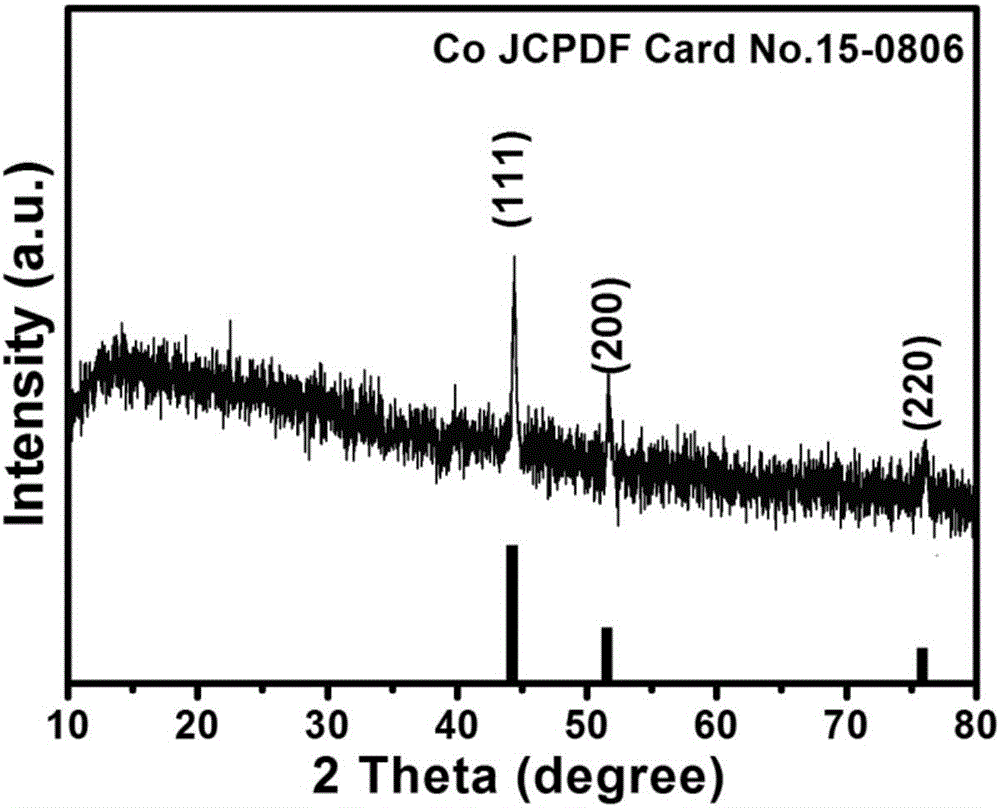

[0037] Take by weighing 1g zinc oxide with electronic balance, 1g tricobalt tetroxide and polyacrylonitrile (PAN) powder (wherein the mass ratio of the three is 1:1:8, and the molar mass M=120000g / mol of PAN) is placed in the 20ml sample bottle, utilizes The pipette accurately pipettes 12ml of N-N dimethylformamide (DMF, PAN accounts for 10% of the mass of DMF), the sample bottle is sealed with raw material tape, heated to 50 ° C, stirred for 36 hours, and finally a uniform electrospun silk liquid.

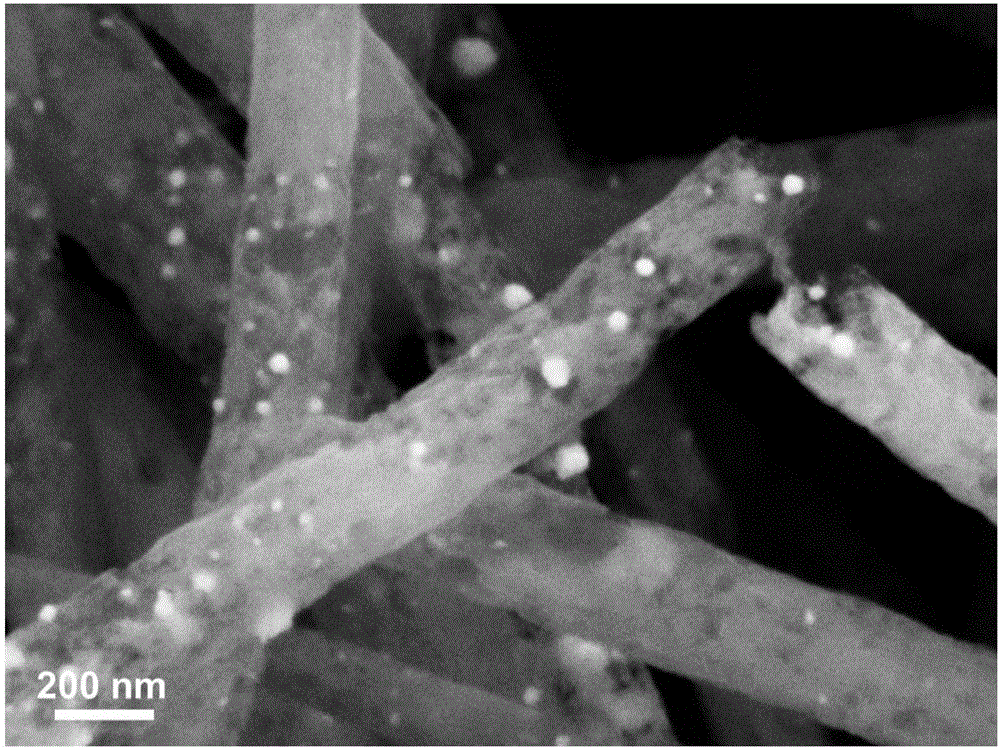

[0038] Electrospinning equipment is used to prepare nanofibers, which are carbonized at 950°C to obtain cobalt / graphitized porous carbon nanofibers. The SEM scanning electron microscope picture of the porous material that present embodiment makes is shown in Figure 4 .

Embodiment 3

[0040]Weigh 1g of zinc oxide, 0.5g of cobalt oxide and 2g of polyacrylonitrile (PAN) powder (wherein the mass ratio of the three is 2:1:4, and the molar mass M of PAN=140000g / mol) with an electronic balance and dissolve in DMF solution Medium (PAN accounted for 20% of DMF mass) was placed in a 20ml sample bottle, heated to 50°C, and stirred for 36 hours to finally obtain a uniformly dispersed electrospinning solution.

[0041] Electrospinning equipment is used to prepare nanofiber membranes, which are carbonized at 1050°C to obtain super-loose and porous carbon nanofibers.

[0042] The prepared cobalt / porous carbon fibers were cleaned and purified in 3M nitric acid at 100°C and 1 MPa to obtain pure graphitized porous carbon nanofibers. The SEM scanning electron micrograph of the porous material that this example makes is shown in Figure 5 .

[0043] It can be seen from the SEM scanning electron microscope that both Examples 1 and 2 can successfully prepare cobalt / graphitize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com