Catalyst used for catalyzing ozone oxidation and preparation method thereof

A technology of ozone oxidation and catalyst, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, etc., to achieve the effects of reducing dissolution, avoiding secondary pollution, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

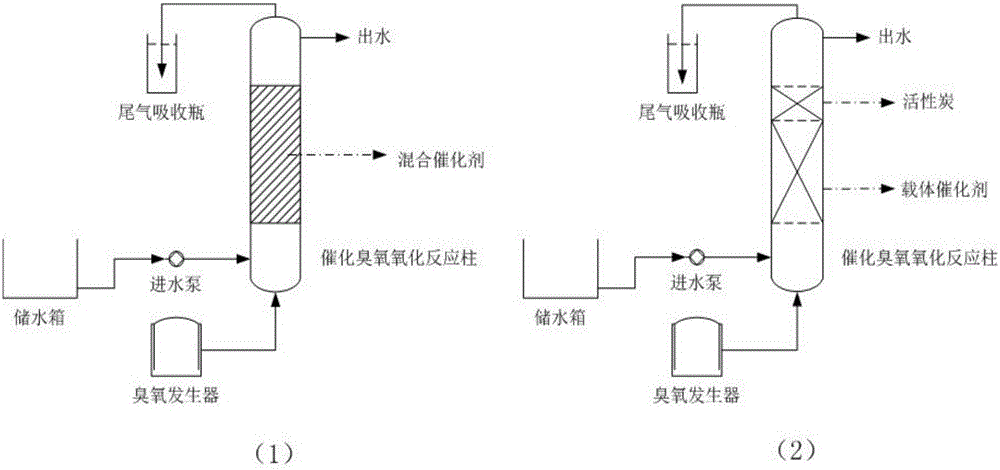

Method used

Image

Examples

Embodiment 1

[0025] Select spherical Al 2 o 3 (The particle size range is 2.5-4.0mm, and the BET specific surface area is 172.9m 2 / g) Prepare the catalyst as a carrier, immerse it in the copper nitrate solution of 0.4mol / L, take it out after immersion for 8h, dry it at room temperature for 4h, place it in a 105°C oven for 4h, and then place it in the air-atmosphere In a Furnace, bake at 200°C for 4.5h, take it out and cool it to room temperature for 8h. The catalyst was prepared by mixing the prepared carrier catalyst with 15% coconut shell-based activated carbon particles.

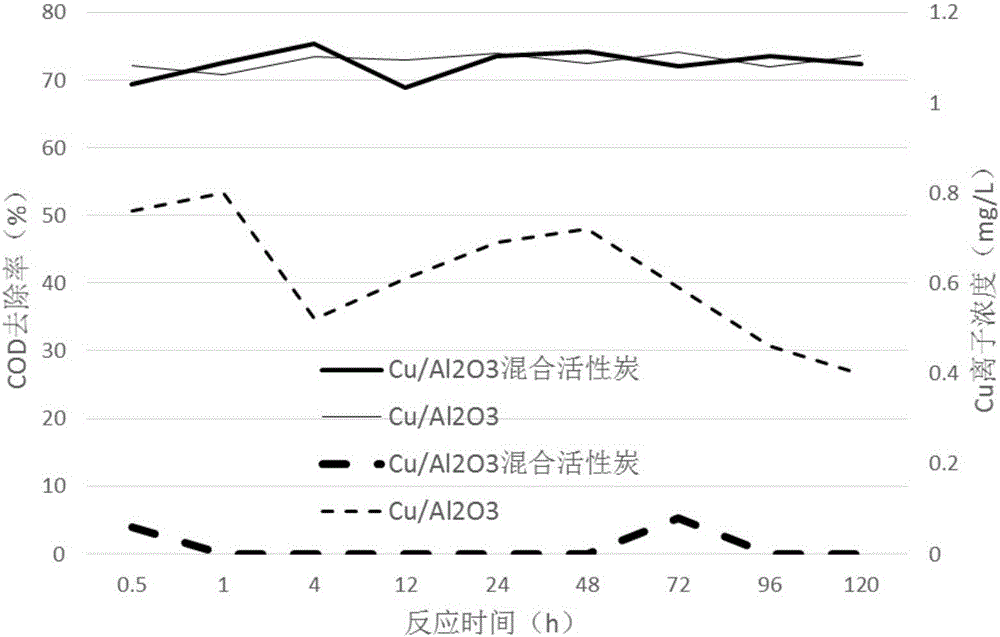

[0026] The Cu / Al of the unmixed activated carbon particles prepared in this example 2 o 3 It is applied to the treatment of RO concentrated water (COD is 109.7mg / L) in a refinery with a mixed catalyst. The ozone dosage is 50mg / L, the ozone concentration is 50mg / L, and the hydraulic retention time is 40min. The treatment effect is shown in figure 2 (The solid line is the COD removal rate, and the dotted line is ...

Embodiment 2

[0028] Select 4A type molecular sieve (BET specific surface area is 453.8m 2 / g) mixed with 10% anthracite-based columnar activated carbon, impregnated in a mixed solution of 0.5mol / L cerium nitrate and 0.5mol / L manganese nitrate, after immersion for 10h, take it out and dry it at room temperature for 6h, and then place it at 100°C Dry it in an oven for 2 hours, place it in a nitrogen atmosphere and bake it in a muffle furnace at a temperature of 300°C for 4 hours, take it out and cool it to room temperature for 12 hours to prepare a mixed catalyst.

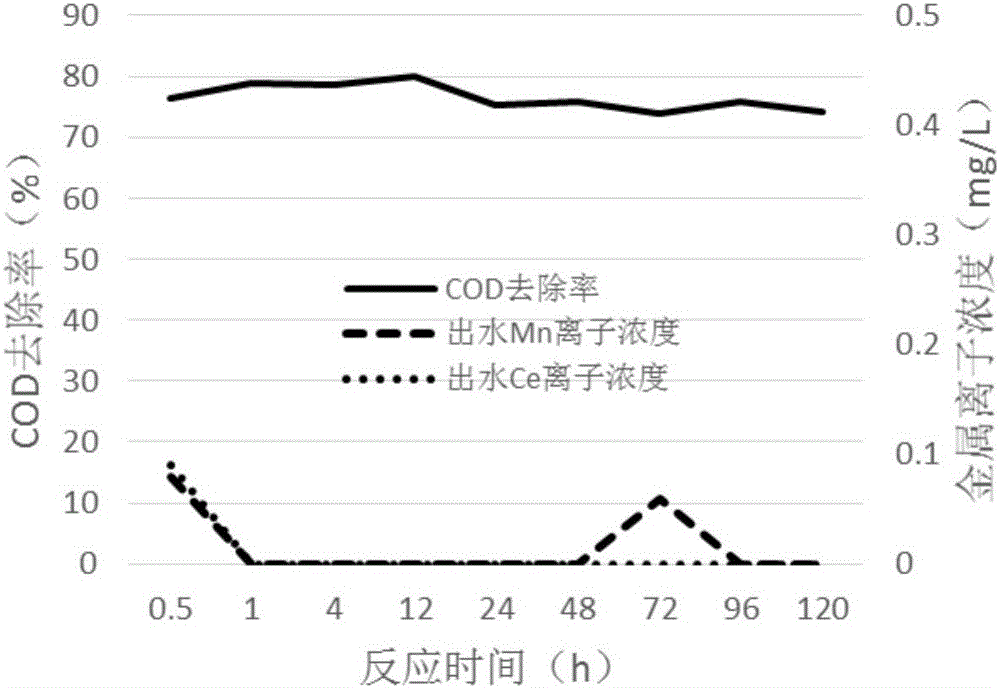

[0029] The mixed catalyst prepared in this example is applied to the treatment of the secondary biochemical effluent (COD is 96.3mg / L) of a refinery that does not meet the standard of salty sewage, the dosage of ozone is 40mg / L, and the ozone concentration is 50mg / L. The hydraulic retention time is 30min, the treatment effect can be seen image 3 . Its COD removal rate is maintained between 70% and 80%. After treatment, it meet...

Embodiment 3

[0031] Select ceramsite (the particle size range is 5.0-6.8mm, the specific surface area is 1.24m 2 / g), spherical Al 2 o 3 (The particle size range is 3.5-5.0mm, and the BET specific surface area is 168.3m 2 / g) were respectively immersed in 0.6mol / L ferric nitrate solution, after soaking for 4 hours, take it out and dry it at room temperature for 8 hours, dry it in an oven at 105°C for 3 hours, then place it in a muffle furnace at 500°C, and roast it under air atmosphere for 2.5 hours h, cooling for 8h to obtain ceramsite carrier and Al 2 o 3 carrier catalyst.

[0032] Take the ceramsite carrier catalyst with a volume ratio of 20% and fill it at the bottom of the catalytic ozonation reaction column, and then take the Al with a volume ratio of 60%. 2 o 3 The carrier catalyst is loaded on the upper layer of the ceramsite carrier catalyst, and finally 20% lignite-based columnar activated carbon is loaded. This catalyst is used to treat alkali slag wastewater (COD is 3421...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com