Experimental system for treating thermal desorption tail gas of organic polluted soil through low temperature plasma

A low-temperature plasma and experimental system technology, which is applied in the field of experimental systems for the thermal desorption of exhaust gas from ionized organic contaminated soils, can solve the problems of large consumption of adsorbents, large fuel consumption, and high processing costs, and achieves short acquisition periods, The effect of preventing condensation and accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

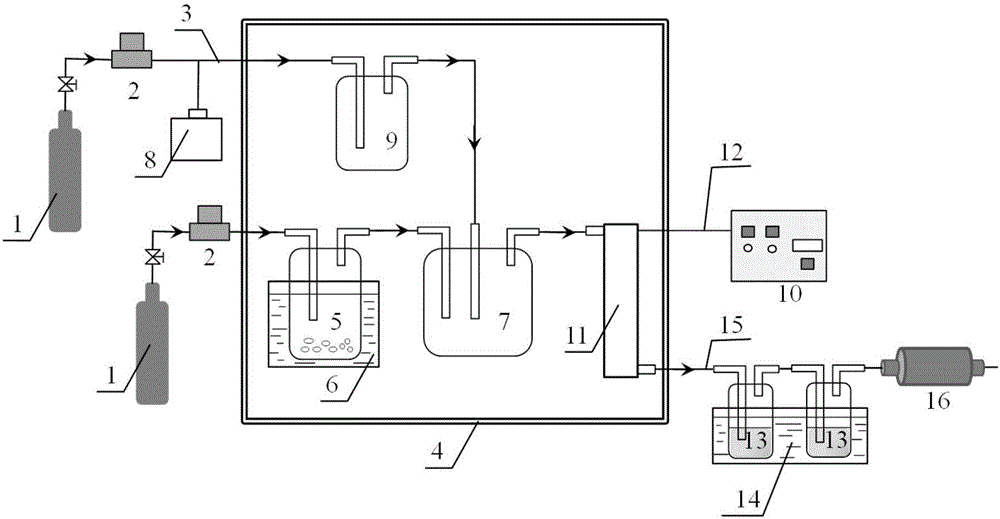

[0064] like figure 1 As shown, the experimental system for low-temperature plasma treatment of organic polluted soil thermal desorption tail gas of the present invention includes a carrier gas device, a heat preservation device, a thermal desorption tail gas generator, a low-temperature plasma treatment device and a tail gas absorption device.

[0065] The gas-carrying device includes a gas cylinder 1, a mass flow meter 2 and a high-temperature-resistant polytetrafluoroethylene inlet pipe 3, wherein the high-temperature-resistant polytetrafluoroethylene inlet pipe 3 is connected to the gas outlet of the gas cylinder, and the mass flowmeter 2 is located at On the high temperature resistant polytetrafluoroethylene intake pipe 3.

[0066] The heat preservation device is a blast drying box 4, and the box door body is provided with an observation window, so that the working conditions in the box can be clearly observed. There are openings on the left and right side walls of the bl...

Embodiment 2

[0071] Utilize the system of embodiment 1 to carry out experiment, specifically as follows:

[0072] The two paths of gas are all air, the flow rate of the gas passing into the pollutant generating device is 0.5mL / min, and the flow rate of the other path of compensation gas is 3mL / min. DDT was selected as the representative pollutant, the heating temperature of the oil bath was 150°C, and the temperature of the blast drying oven was 120°C. The two gases were mixed in the buffer bottle and then entered into the low-temperature plasma reactor. Corona discharge low-temperature plasma, the diameter of the reactor is 15cm, and the effective length is 0.9m. The pulse discharge voltage was set to 15KV, 20KV, 25KV and 30KV respectively, and the fixed pulse frequency was 50HZ. The removal of DDT thermal desorption tail gas under different discharge voltages was investigated. The results showed that the degradation efficiency of DDT increased with the increase of discharge voltage. Lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com