Recovery method of magnesium sulfate monohydrate washing liquid

A recovery method, magnesium sulfate technology, applied in the direction of magnesium sulfate, alkali metal chloride, etc., can solve problems such as environmental pollution and waste of resources, and achieve the effects of reducing costs, increasing total volume, and reducing waste liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

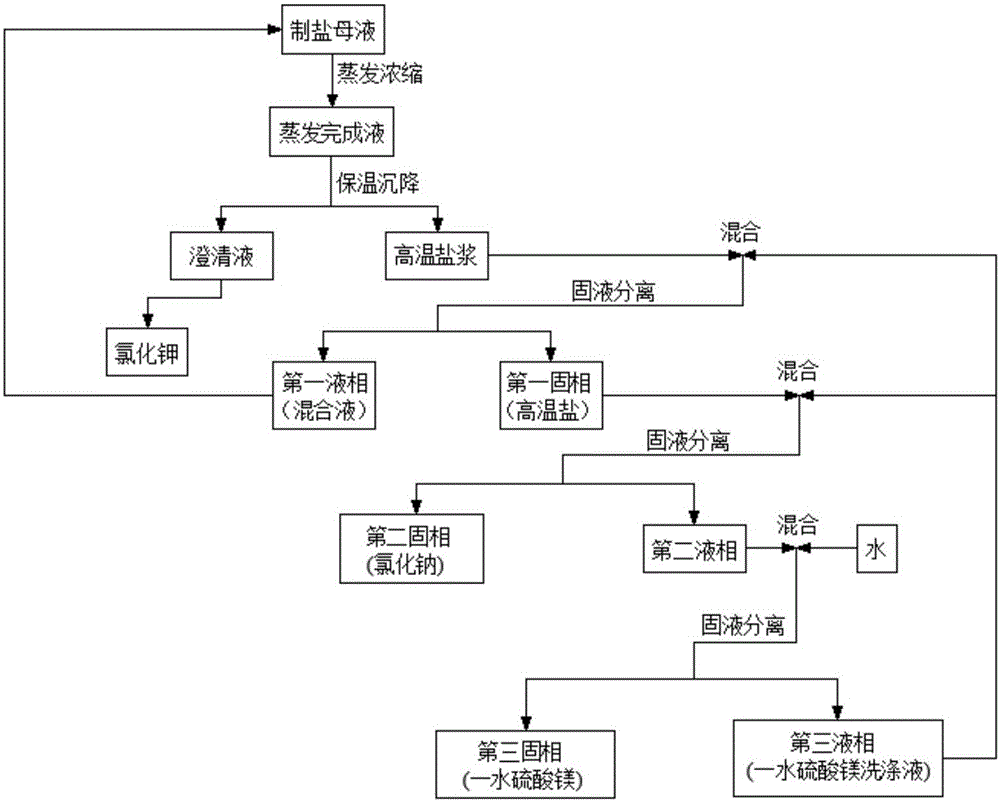

[0034] Such as figure 1 Shown, a kind of method that produces potassium chloride, sodium chloride, magnesium sulfate monohydrate with salt mother liquor, uses the recovery method of magnesium sulfate monohydrate washing liquid, comprises the following steps:

[0035] (1) prepare the salt-making mother liquor in the Potassium Chloride technique and obtain evaporation completion liquid after evaporation and concentration;

[0036] (2) Evaporation is completed and the liquid is subjected to heat preservation and settlement to obtain clarified liquid and high-temperature salt slurry; the obtained clarified liquid is produced to produce potassium chloride product;

[0037] (3) After the high-temperature salt slurry is mixed with a part of the magnesium sulfate monohydrate washing solution obtained in step (5), the solid-liquid separation is carried out for the first time to obtain the first liquid phase and the first solid phase. The first liquid phase is the mixed liquid, and the...

Embodiment 2

[0044] Such as figure 1 Shown, a kind of method that produces potassium chloride, sodium chloride, magnesium sulfate monohydrate with salt-making mother liquor, uses the recovery method of magnesium sulfate monohydrate washing liquid, and its step other is identical with embodiment 1, and difference is: In the present embodiment, in step (3), the volume ratio of the mixed high-temperature salt slurry and magnesium sulfate monohydrate washing liquid is 1:0.5; the solid-liquid separation in steps (3), (4) is centrifugal separation, and step ( 5) The solid-liquid separation in is normal pressure filtration.

[0045] In the present embodiment, adopt the method provided by the invention, the total amount of potassium chloride, sodium chloride and magnesium sulfate monohydrate product that obtains increases 5.3% (weight) than original technology.

Embodiment 3

[0047] Such as figure 1 Shown, a kind of method that produces potassium chloride, sodium chloride, magnesium sulfate monohydrate with salt-making mother liquor, uses the recovery method of magnesium sulfate monohydrate washing liquid, and its step other is identical with embodiment 1, and difference is: In the present embodiment, in step (3), the volume ratio of the mixed high-temperature salt slurry and magnesium sulfate monohydrate washing liquid is 1:0.8; the solid-liquid separation in step (3) is normal pressure filtration, and in step (4) The solid-liquid separation is standing at normal temperature, and the solid-liquid separation in step (5) is centrifugation.

[0048] In the present embodiment, adopt the method provided by the invention, the total amount of potassium chloride, sodium chloride and magnesium sulfate monohydrate product that obtains increases 6.1% (weight) than original technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com