Hydrothermal preparation method of zinc oxide/two-dimensional layered titanium carbide composite material

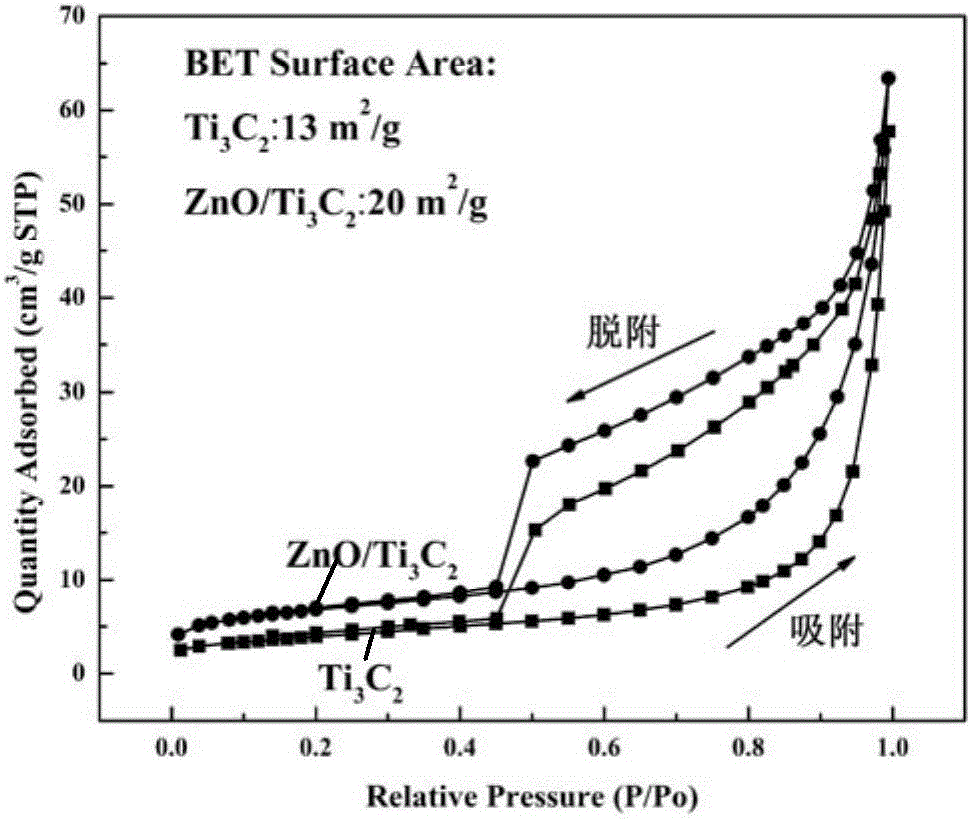

A two-dimensional layered, composite material technology, applied in the direction of zinc oxide/zinc hydroxide, etc., to achieve the effects of easy operation and control, large specific surface area, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Refined powder

[0023] Refinement of ternary layered Ti with a purity greater than 97% by high energy ball milling 3 AlC 2 Powder, high energy ball milling conditions: ball stone, ternary layered Ti 3 AlC 2 The mass ratio of powder and ball milling medium (absolute ethanol) is 10:1:1, the ball milling speed is 400r / min, the high energy ball milling time is 2h, and then the obtained solid-liquid mixture is dried at 50°C to obtain the particle size About 56μm Ti 3 AlC 2 Powder;

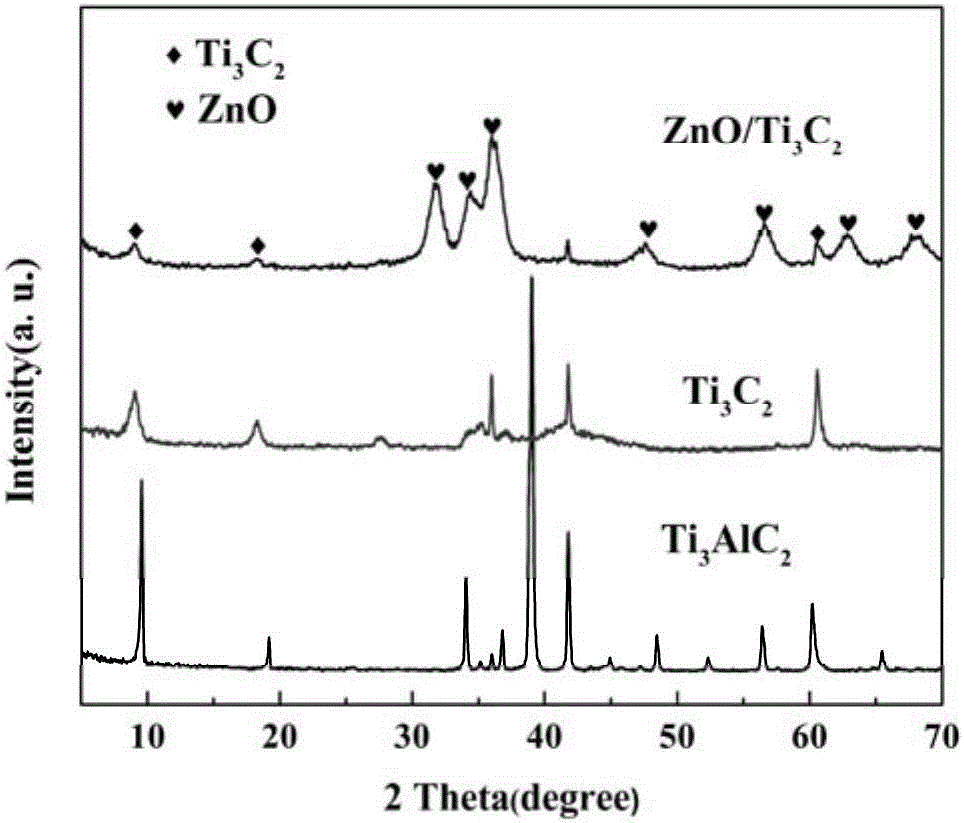

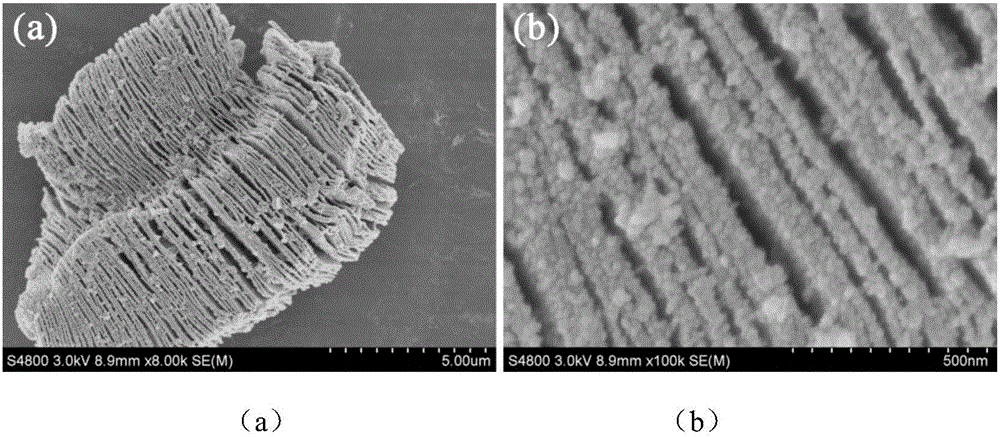

[0024] 2) Two-dimensional layered titanium carbide (Ti 3 C 2 ) preparation

[0025] 2g Ti 3 AlC 2 The powder was immersed in 50mL of hydrofluoric acid solution with a mass concentration of 45%, and reacted for 12h under magnetic stirring to complete the ternary layered Ti 3 AlC 2 The powder is subjected to corrosion treatment, and then centrifugally cleaned with deionized water until the pH value is 5-6, and the obtained solid sample is dried at room temperature to obtain a two-di...

Embodiment 2

[0032] 1) Refined powder

[0033] Refinement of ternary layered Ti with a purity greater than 97% by high energy ball milling 3 AlC 2 Powder, high-energy ball milling condition ball stone, ternary layered Ti 3 AlC 2 The mass ratio of powder and ball milling medium is 10:1:1, the ball milling speed is 400r / min, the high energy ball milling time is 4h, and then the obtained solid-liquid mixture is dried at 50°C to obtain Ti with a particle size of about 8 μm. 3 AlC 2 Powder;

[0034] 2) Two-dimensional layered titanium carbide (Ti 3 C 2 ) preparation

[0035] 5g Ti 3 AlC 2 The powder was immersed in 100mL of hydrofluoric acid solution with a mass concentration of 40%, and reacted for 48h under magnetic stirring; to complete the ternary layered Ti 3 AlC 2 The powder is subjected to corrosion treatment, and then centrifugally cleaned with deionized water until the pH value is 5-6, and the obtained solid sample is dried at room temperature to obtain a two-dimensional lay...

Embodiment 3

[0039] 1) Refined powder

[0040] Refinement of ternary layered Ti with a purity greater than 97% by high energy ball milling 3 AlC 2 Powder, high-energy ball milling condition ball stone, ternary layered Ti 3 AlC 2 The mass ratio of powder and ball milling medium is 10:1:1, the ball milling speed is 400r / min, the high energy ball milling time is 3h, and then the obtained solid-liquid mixture is dried at 55°C to obtain Ti with a particle size of about 50μm. 3 AlC 2 Powder;

[0041] 2) Two-dimensional layered titanium carbide (Ti 3 C 2 ) preparation

[0042] 8g Ti 3 AlC 2 The powder was immersed in 160mL of hydrofluoric acid solution with a mass concentration of 40%, and reacted for 72h under magnetic stirring; to complete the ternary layered Ti 3 AlC 2 The powder is subjected to corrosion treatment, and then centrifugally cleaned with deionized water until the pH value is 5-6, and the obtained solid sample is dried at room temperature to obtain a two-dimensional lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com