Novel production process for dichloroacetonitrile

A dichloroacetonitrile, a new process technology, applied in the purification/separation of carboxylic acid nitrile, organic chemistry, etc., can solve the problems of low reaction rate, low product content, high equipment requirements, etc., to reduce the risk of operation and reduce the reaction conditions , the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

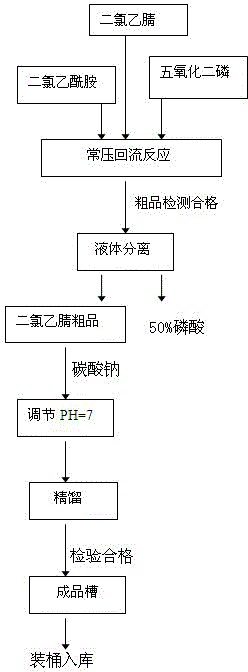

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Add 80Kg of dichloroacetonitrile, 300Kg of dichloroacetamide, and 360Kg of phosphorus pentoxide into a 3000L reactor, raise the temperature and stir; control the temperature at about 110°C and reflux for 4 hours at normal pressure, and stop the reflux if there is no dichloroacetamide in the detection system , recovery of crude dichloroacetonitrile; solid metaphosphoric acid at the bottom of rough steaming, adding an appropriate amount of water to form liquid phosphoric acid and release it from the bottom of the kettle. Adjust the pH of the crude product obtained above to 7 with sodium carbonate, then pump it into the fine steamer, control the temperature in the finer steamer at about 110°C, recover qualified products, and put them into barrels for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com