Preparation method of brake hose joint

A technology of brake pipe and head, which is applied in the field of preparation of brake pipe joints, can solve the problems of wear resistance, medium resistance, oxidation resistance, general corrosion resistance, non-competitive cost-effectiveness, and a large number of spare parts, etc., to achieve improved Strength and corrosion resistance, reducing overheating sensitivity and temper brittleness, and improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

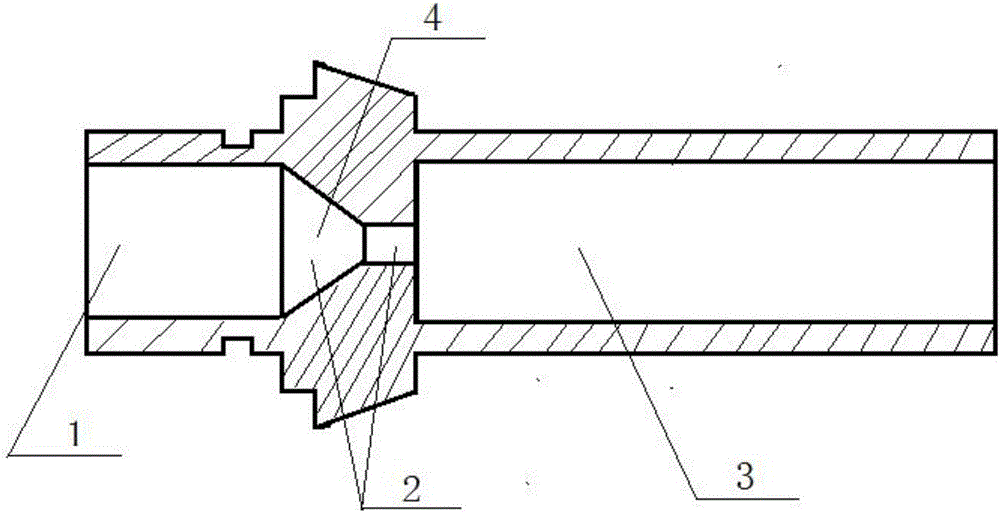

Image

Examples

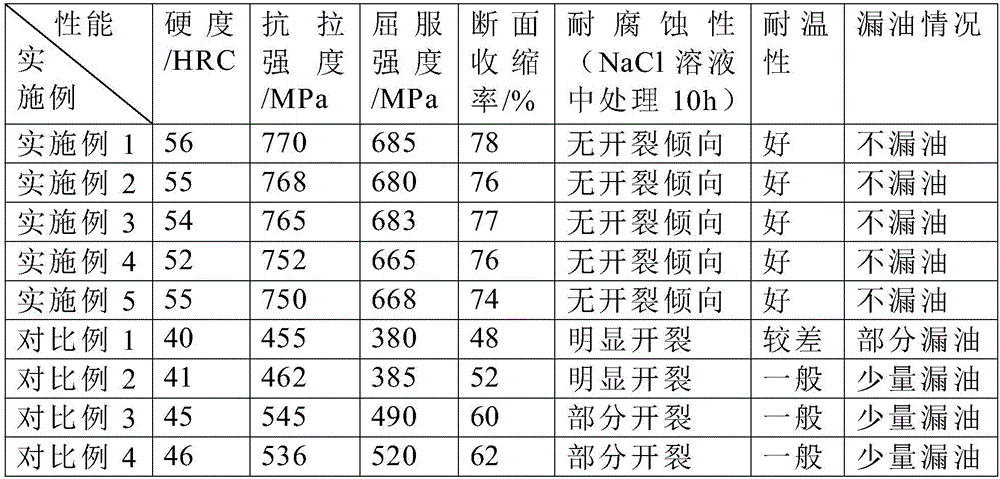

Embodiment 1

[0033] Raw materials for steelmaking: according to the composition and mass percentage of brake pipe joints: C: 0.19%, Si: 0.10%, Mn: 0.90%, B: 0.12%, Ti: 0.055%, Al: 0.25%, Mo: 0.72%, V: 0.20%, Nb: 0.08%, La: 0.015%, P ≤ 0.02%, S ≤ 0.02%, the balance is Fe, and melted into molten steel at 1320°C. After smelting, the molten steel is poured with full protection of argon seal. And rolled into steel plate; during rolling, the rolling temperature is 1000°C, the finish rolling temperature is 900°C, the spinning temperature is 860°C, and the coiling temperature is 750°C;

[0034] Cold extrusion molding: the steel is subjected to surface pickling and derusting, limestone coating, and phosphating treatment in sequence, and then cold extrusion molding to obtain a brake pipe joint blank;

[0035] Heat treatment: heat up the brake pipe joint blank at a rate of 8 °C / min to 530 °C, then at a rate of 6 °C / min to 820 °C, and then at a rate of 10 °C / min to 1020 °C with quenching oil Quenchin...

Embodiment 2

[0038] Raw material steelmaking: according to the composition and mass percentage of the brake pipe joint: C: 0.18%, Si: 0.08%, Mn: 1.00%, B: 0.01%, Ti: 0.06%, Al: 0.22%, Mo: 0.68%, V: 0.22%, Nb: 0.05%, La: 0.012%, P ≤ 0.02%, S ≤ 0.02%, the balance is Fe, and melted into molten steel at 1340°C. After smelting, the molten steel is poured with full protection of argon seal. And rolled into steel plate; during rolling, the rolling temperature is 990°C, the finish rolling temperature is 890°C, the spinning temperature is 870°C, and the coiling temperature is 755°C;

[0039] Cold extrusion molding: the steel is subjected to surface pickling and derusting, limestone coating, and phosphating treatment in sequence, and then cold extrusion molding to obtain a brake pipe joint blank;

[0040] Heat treatment: heat up the brake pipe joint blank at a rate of 9 °C / min to 535 °C, then at a rate of 6 °C / min to 800 °C, and then at a rate of 12 °C / min to 1040 °C with quenching oil Quenching tr...

Embodiment 3

[0043] Raw materials for steelmaking: according to the composition and mass percentage of brake pipe joints: C: 0.18%, Si: 0.11%, Mn: 0.88%, B: 0.08%, Ti: 0.05-0.06%, Al: 0.28%, Mo: 0.75 %, V: 0.18%, Nb: 0.008-0.14%, La: 0.018%, P≤0.02%, S≤0.02%, the balance is Fe, and melted into molten steel at 1310 ° C, the molten steel is smelted and sealed with argon Full protection pouring, and rolling into steel plate; rolling temperature is 1010°C, finish rolling temperature is 905°C, spinning temperature is 855°C, coil collection temperature is 745°C;

[0044] Cold extrusion molding: the steel is subjected to surface pickling and derusting, limestone coating, and phosphating treatment in sequence, and then cold extrusion molding to obtain a brake pipe joint blank;

[0045] Heat treatment: heat up the brake pipe joint blank to 525°C at a rate of 8°C / min, then to 850°C at a rate of 7°C / min, and then to 990°C at a rate of 9°C / min with quenching oil Quenching treatment, heat preservation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com