High-activity carbon fiber felt electrode material and preparation method and application thereof

A technology of carbon fiber felt and electrode material, which is applied in the field of highly active carbon fiber felt electrode material and its preparation, can solve the problem of low electrocatalytic activity, achieve improved electrocatalytic activity, increase active specific surface area, improve energy conversion efficiency and charge and discharge The effect of current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

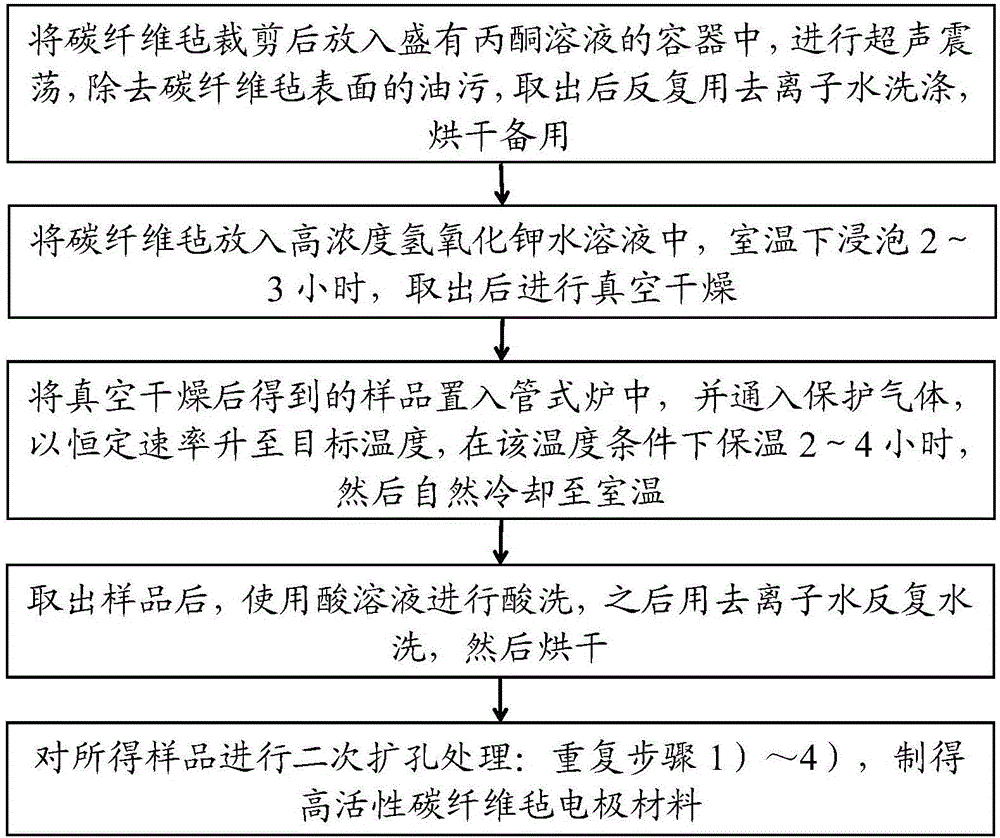

[0027] Such as figure 1 As shown, the preparation method of a kind of highly active carbon fiber felt electrode material provided by the embodiment of the present invention comprises the following steps:

[0028] 1) After cutting the carbon fiber felt, put it into a container filled with acetone solution, carry out ultrasonic vibration, remove the oil stain on the surface of the carbon fiber felt, wash it repeatedly with deionized water after taking it out, and dry it for later use;

[0029] 2) Put the carbon fiber felt into a high-concentration potassium hydroxide aqueous solution, soak it at room temperature for 2 to 3 hours, and vacuum dry it after taking it out;

[0030] 3) Put the sample obtained after vacuum drying into a tube furnace, and pass through a protective gas, raise it to the target temperature at a constant rate, keep it warm at this temperature for 2 to 4 hours, and then cool it naturally to room temperature;

[0031] 4) After taking out the sample, use an a...

Embodiment 1

[0041] In this embodiment, when preparing the highly active carbon fiber felt electrode material for all-vanadium redox flow battery, the following steps are adopted:

[0042] 1) Cut the carbon fiber felt into a size of 30mm×30mm×5mm, put it into a beaker filled with acetone solution, and place the beaker in an ultrasonic washing tank for 30 minutes to remove the oil on the surface of the carbon fiber felt. After taking it out, wash it repeatedly with deionized water, and put it in an oven to dry at 60°C for later use.

[0043] 2) Prepare 6 mol / L potassium hydroxide aqueous solution, put the cut carbon fiber mat into the solution, soak it at room temperature for 3 hours, take it out and put it in a vacuum drying oven for 12 hours at 60°C.

[0044] 3) Put the sample into a tube furnace, and pass nitrogen into the furnace as a protective gas protection, first raise the furnace temperature to 800°C at a constant rate of 5°C / min, and then keep it at this temperature for 2 hours, a...

Embodiment 2

[0053] In this embodiment, when preparing the highly active carbon fiber felt electrode material for all-vanadium redox flow battery, the following steps are adopted:

[0054] 1) Cut the carbon fiber felt into a size of 50mm×50mm×5mm, put it into a beaker filled with acetone solution, and place the beaker in an ultrasonic washing tank for 30 minutes to remove the oil on the surface of the carbon fiber felt. After taking it out, wash it repeatedly with deionized water, and put it in an oven to dry at 60°C for later use.

[0055] 2) Configure an aqueous solution of 8 mol / L potassium hydroxide. Put the carbon fiber felt into the solution and soak it at room temperature for 3 hours, take it out and put it in a vacuum drying oven for 12 hours at 60°C.

[0056] 3) Put the sample into a tube furnace, and feed nitrogen into the furnace as a protective gas. The furnace temperature n was first raised to 700°C at a constant rate of 8°C / min, then kept at this temperature for 2 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com