Regenerated fibroin protein gel mask

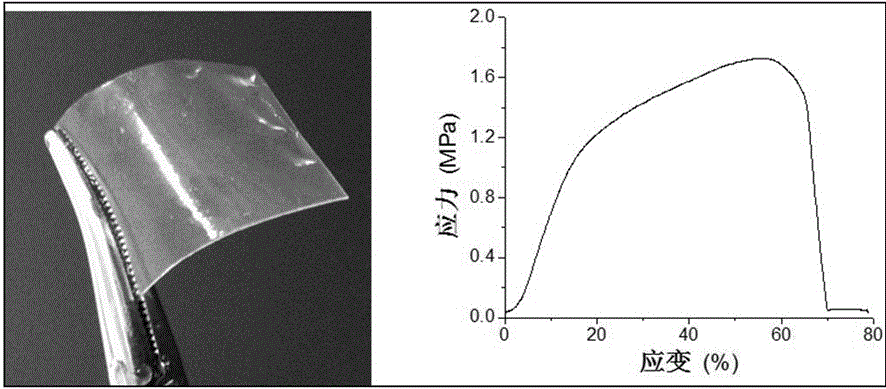

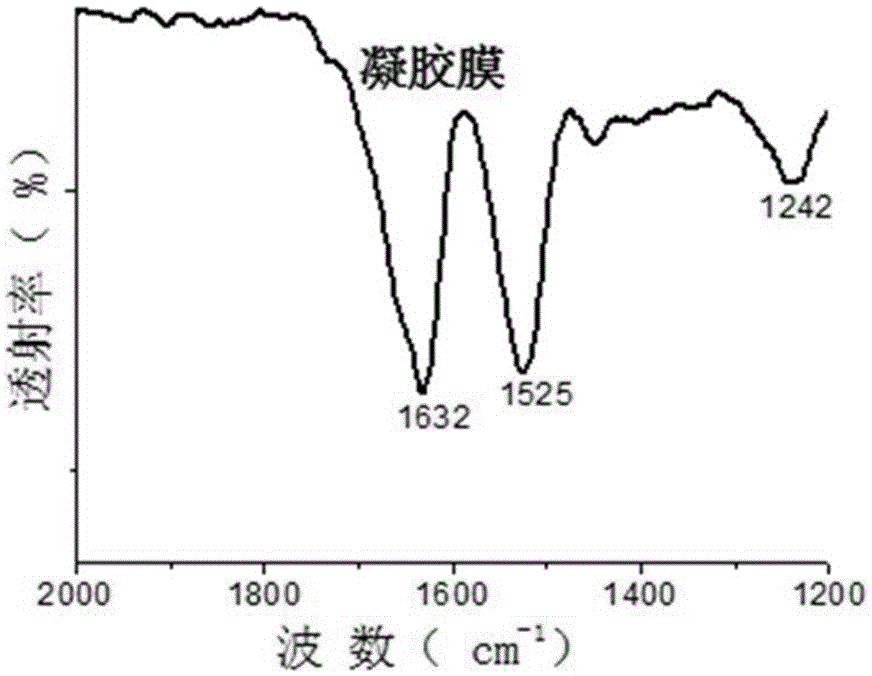

A technology for regenerating silk fibroin and silk fibroin, which is applied in the field of transparent silk fibroin gel membranes, can solve problems such as poor physical and mechanical properties and affect the application prospects of silk fibroin gels, and achieve excellent stability and good cell Effects of biocompatibility and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Natural mulberry silk was boiled with 0.5wt% sodium bicarbonate solution for 60 minutes to obtain degummed mulberry silk;

[0041] (2) Dissolve the degummed silk in step (1) in 8% ZnCl at a concentration of 10wt% 2 In -90% formic acid, the dissolution temperature is 25°C, and the dissolution time is 3 hours to obtain a silk fibroin solution. After drying at a temperature of 20°C and a relative humidity of 65%, a CaCl-containing solution is obtained. 2 silk fibroin film;

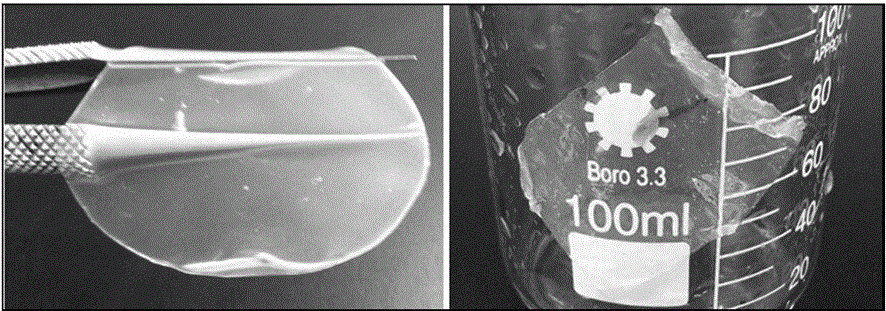

[0042] (3) the CaCl obtained in step (2) 2 The silk fibroin film is soaked in running water and rinsed for 5 hours to obtain a regenerated silk fibroin gel film with a water content of about 65%.

Embodiment 2

[0044] (1) Natural tussah silk was degummed by boiling 0.5wt% sodium carbonate solution for 30 minutes, and the degummed tussah silk was obtained after repeating 3 times;

[0045] (2) Dissolve the degummed silk in step (1) in 4% CaCl at a concentration of 8wt% 2 In -88% formic acid, the dissolution temperature is 35°C, and the dissolution time is 4h to obtain a silk fibroin solution. After drying at a temperature of 30°C and a relative humidity of 60%, a CaCl-containing solution is obtained. 2 silk fibroin film;

[0046] (3) the CaCl obtained in step (2) 2The silk fibroin film was immersed in 25% ethanol aqueous solution for 10 hours, and the liquid was changed every half hour, and then washed in running water for 3 hours to obtain a regenerated tussah silk fibroin gel film with a water content of about 60%.

Embodiment 3

[0048] (1) Natural mulberry silk was degummed by boiling with 0.25wt% sodium bicarbonate solution for 30 minutes, and repeated 3 times to obtain degummed mulberry silk;

[0049] (2) Dissolve the degummed silk in step (1) in 4% MgCl at a concentration of 8wt% 2 In -98% formic acid, the dissolution temperature is 35°C, and the dissolution time is 1h to obtain a silk fibroin solution. After drying at a temperature of 30°C and a relative humidity of 40%, a CaCl-containing solution is obtained. 2 silk fibroin film;

[0050] (3) the MgCl obtained in step (2) 2 The silk fibroin film was soaked in running water and rinsed for 5 hours to obtain a regenerated silk fibroin gel film with a water content of about 55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com