Catalyst for preparing propylene through propane dehydrogenation, preparation method of catalyst, and method for propylene through propane dehydrogenation

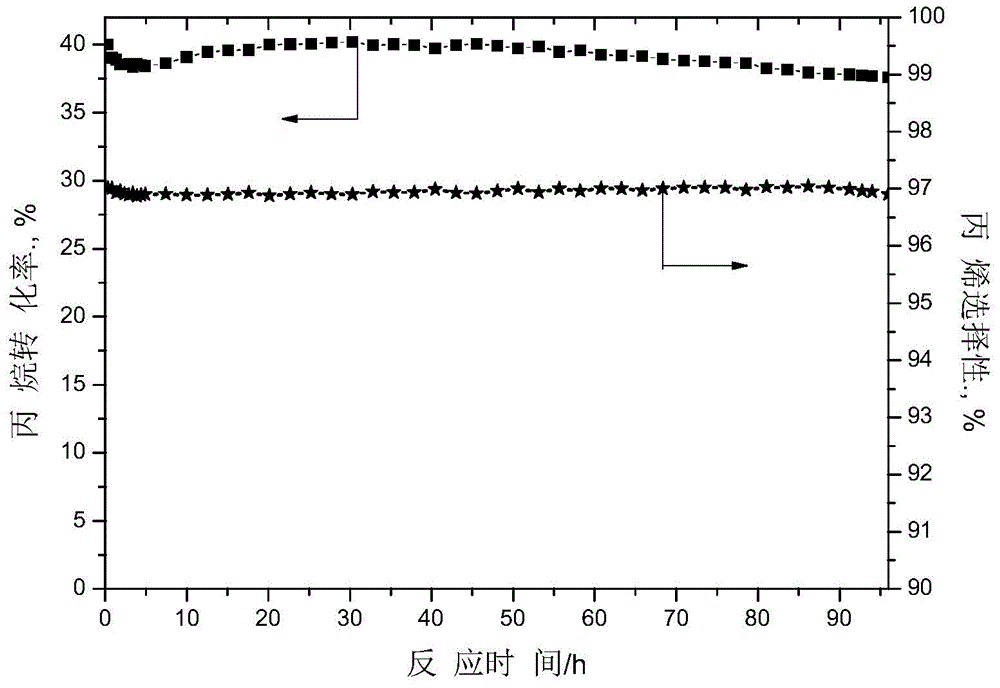

A propane dehydrogenation and catalyst technology, applied in the field of propane dehydrogenation to propylene, can solve the problem of easy coking of the catalyst, achieve good propane dehydrogenation conversion rate, and improve the effect of propylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] This preparation example is used to illustrate the preparation of the mesoporous molecular sieve in the preparation of the catalyst for propane dehydrogenation to propylene of the present invention.

[0054] 16.4g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123, Sigma-Aldrich Chemistry) was dissolved in about 120ml of water, then added with a concentration of 1.5M hydrochloric acid 320ml, stirred for 1h , then add 32.2g of tetraethyl silicate dropwise, after the dropwise addition, the temperature is raised to about 40°C, stirred for 20h, then transferred to a small stainless steel tank for crystallization at 120°C for 24h, then filtered, washed, dried, and roasted to obtain mesoporous Molecular sieve SBA-15.

[0055] The specific surface area of mesoporous molecular sieve is 731.2228m 2 / g, the pore volume is 1.0957cm 3 / g, the pore diameter is 6.4121nm.

preparation example 2

[0057] This preparation example is used to illustrate the preparation of the catalyst for propane dehydrogenation to propylene of the present invention, and the preparation of mesoporous molecular sieves.

[0058] Dissolve 3.5g of NaOH in about 300ml of deionized water, add 22.5g of cetyltrimethylammonium bromide (Tianjin Jinke Fine Chemical Research Institute), then add 75ml of deionized water, stir and heat up to completely dissolve ; Then the temperature dropped to 30°C, 40.8g of tetraethyl silicate was added dropwise, and stirred at room temperature for 4h; then the material was transferred to a small stainless steel tank with PTFE lining, raised to 150°C at 2°C / min, and crystallized for 8h , filtered, washed, dried, and roasted to obtain white powder MCM-48.

[0059] The specific surface area of mesoporous molecular sieve is 989.1054m 2 / g, the pore volume is 1.0596cm 3 / g, the pore diameter is 3.9487nm.

Embodiment 1

[0061] This example is used to illustrate the preparation of the catalyst for propane dehydrogenation to propylene of the present invention.

[0062] Dissolve 0.1608g of zinc nitrate (Sinopharm Chemical Reagent Co., Ltd.) and 0.1824g of magnesium nitrate (Tianjin Unilab Chemical Reagent Co., Ltd.) in water, and the calculated amount of chloroplatinic acid (Tianjin Guangfu Technology Development Co., Ltd.) ), then impregnated with 3.0 g of the above-mentioned SBA-15 molecular sieve carrier, dried at 120°C for 2h, calcined at 550°C for 8h, and pressed into tablets to obtain a catalyst precursor;

[0063] The catalyst precursor was reduced at 425° C. for 2 h in a hydrogen atmosphere to obtain a PtZnMg / SBA-15 catalyst.

[0064] The composition of the catalyst is as follows: SBA-15 molecular sieve contains 97.74% by weight, Pt contains 0.50% by weight, Zn contains 1.18% by weight, and Mg contains 0.58% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com