Perfluoroether elastomer and preparation method thereof

A technology of elastomer and perfluoroether, which is applied in the field of preparation of fluoroelastomer to achieve the effect of increasing flexibility and enhancing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

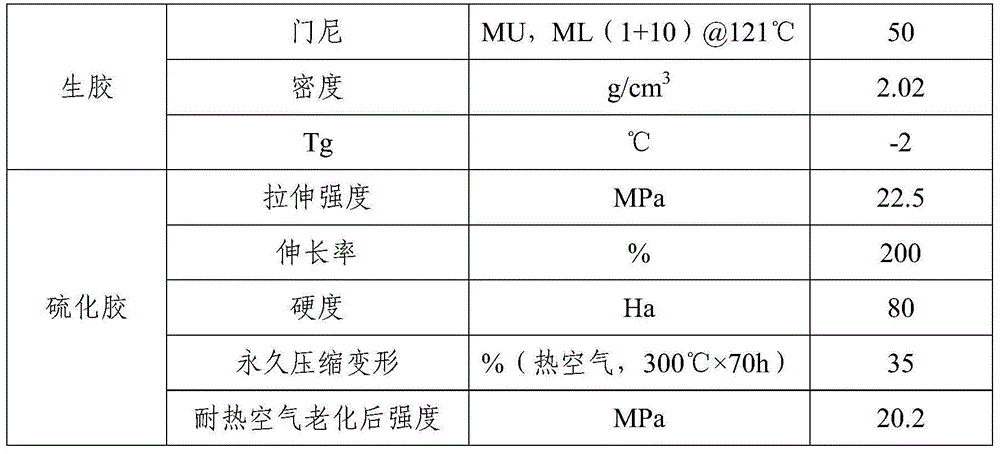

Embodiment 1

[0031] In a 5L stainless steel reactor equipped with a stirrer, add 3L of deionized water, 2g of dipotassium hydrogen phosphate, 2g of emulsifier (a mixture of perfluoropolyether peroxide and sodium octyl sulfonate with a mass ratio of 1:1), After repeating nitrogen pressurization and evacuating and degassing, the mixed monomer of TFE / PMVE / PPVE=60 / 35 / 5 (molar ratio) was added to the reactor with a compressor, and the pressure was increased to 1.2 MPa at 80°C. 10g of perfluorobromoethyl vinyl ether and 10g of 15% (wt) ammonium persulfate aqueous solution were pumped into the pump to initiate the polymerization reaction. When the reactor pressure drops to 1.0MPa, add ICHF 2 CHF 2 I 5g, while adding VDF / HFP=80 / 20TFE / PMVE / PPVE=60 / 35 / 5 (molar ratio) of mixed monomers, keeping the pressure in the reactor at 1.2MPa.

[0032] As the reaction progresses, 10 g of the initiator aqueous solution, that is, 15% (wt) ammonium persulfate aqueous solution, is added once every 4 hours. The reacti...

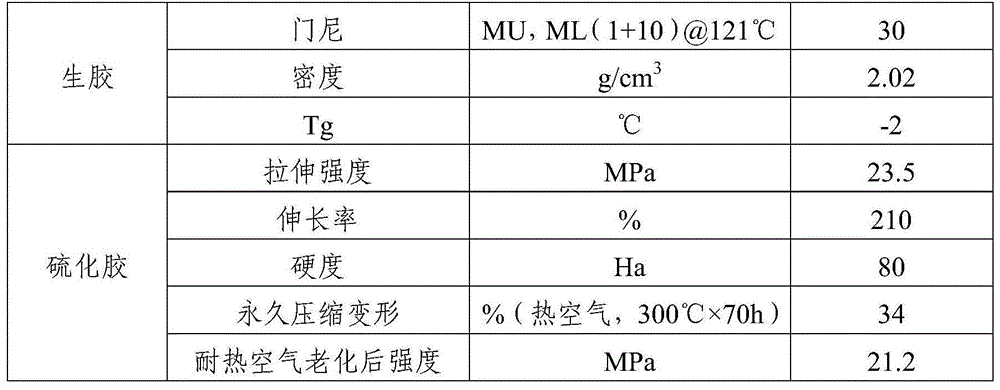

Embodiment 2

[0039] In a 5L stainless steel reactor with a stirrer, add 3L of non-ionized water, 2g of dipotassium hydrogen phosphate, 2g of emulsifier (perfluoropolyether peroxide and sodium octyl sulfonate with a mass ratio of 1:1), repeat After pressurizing with nitrogen and evacuating and degassing, the mixed monomer of TFE / PMVE / PEVE=60 / 35 / 5 (molar ratio) is added to the reactor with a compressor, and the pressure is increased to 1.2 MPa at 80°C and passed through a metering pump 10g of perfluorobromoethyl vinyl ether and 10g of 15% (wt) ammonium persulfate aqueous solution were pressed into it to initiate the polymerization reaction. When the pressure of the reactor drops to 1.0MPa, add I(CF 2 CF 2 ) 2 I 8g, while adding TFE / PMVE / PEVE=60 / 35 / 5 (molar ratio) of mixed monomers, keeping the pressure in the reactor at 1.2 MPa.

[0040] As the reaction progresses, 10 g of 15% (wt) ammonium persulfate aqueous solution of initiator is added once every 4 h. The reaction lasted for about 10 hours...

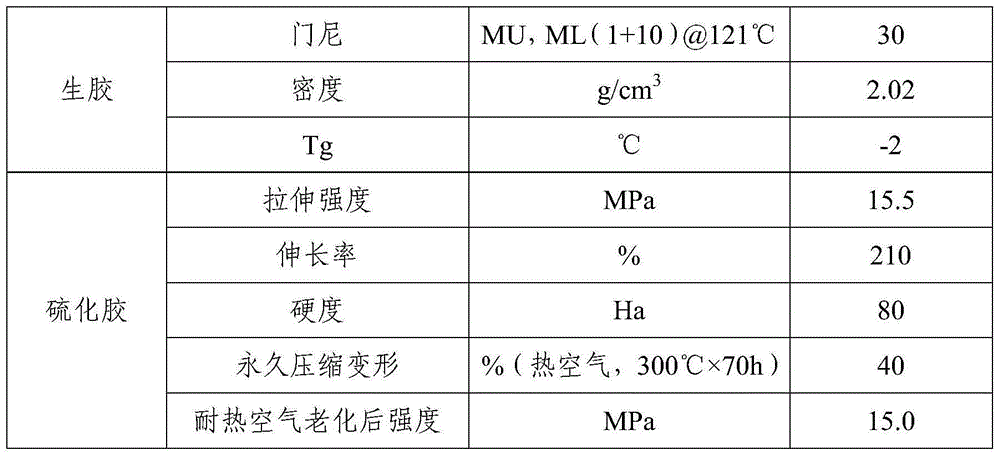

Embodiment 3

[0044] In a 5L stainless steel reactor with a stirrer, add 3L of non-ionized water, 2g of dipotassium hydrogen phosphate, and 2g of emulsifier. After repeated nitrogen pressurization and evacuation and degassing, add TFE / PMVE / to the reactor with a compressor. PEVE / PPVE=65 / 30 / 2 / 3 (molar ratio) of mixed monomers, the pressure is increased to 1.2MPa at 80°C, and 10g of perfluorobromoethyl vinyl ether, 10g of 15% ( wt) Aqueous ammonium persulfate solution initiates the polymerization reaction, and when the pressure of the reactor drops to 1.0MPa, add I(CF 2 ) 5 I 4g was added at the same time with TFE / PMVE / PEVE / PPVE=65 / 30 / 2 / 3 (molar ratio) of mixed monomers, keeping the pressure in the reactor at 1.2MPa.

[0045] As the reaction progresses, 10 g of 15% (wt) ammonium persulfate aqueous solution of initiator is added once every 4 h. The reaction lasted for about 8 hours, and about 4.5 kg of elastomer emulsion was obtained. Agglomerate with sodium chloride aqueous solution, wash, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com