Application of functional ionic liquid and method of extracting lithium from salt lake brine

An ionic liquid and extraction technology, applied in the field of extraction, can solve problems such as equipment corrosion, low extraction efficiency, and lack of lithium extraction function, and achieve the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

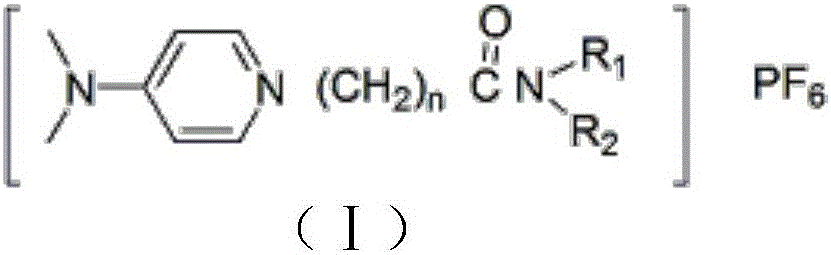

[0049] The extractant is 4-N, N, dimethyl-N'-diethylcarbonylethylpyridine hexafluorophosphate, and its structural formula is as follows:

[0050]

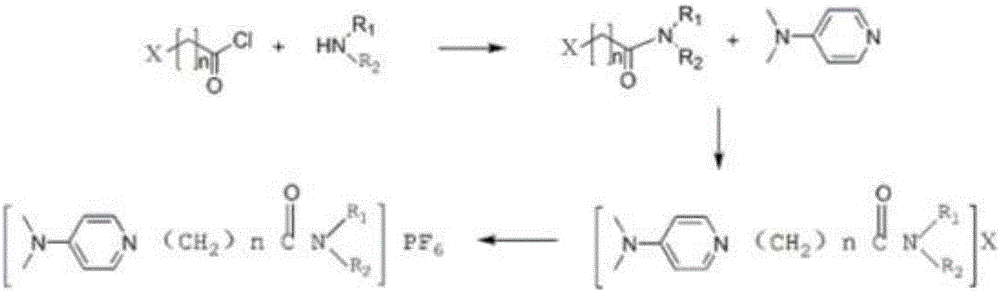

[0051] 【resolve resolution】

[0052] Add 26.65g of diethylamine, 80ml of 1,2-dichloroethane and 12.12g of triethylamine into a 500ml three-necked flask, place the system in an ice-salt bath and drop it below zero, and add 11.2g of ethyl chloride dropwise. 35 ml of 1,2-dichloroethane solution of acid chloride, the rate of addition is controlled to ensure that the reaction temperature is maintained within 10°C. After the dropwise addition, the reaction system was transferred to room temperature and reacted for 3 h.

[0053] Add 100ml of 1M hydrochloric acid solution dropwise to quench the experiment, let stand, separate the phases, and keep the organic phase; the organic phase was washed with 100ml of 1M sodium hydroxide solution, 100ml of water, and 100ml of saturated brine, and finally dried over anhydrous sodium sulfate. Afte...

Embodiment 2

[0059] The extractant is 4-N, N, dimethyl-N'-diethylcarbonylpropylpyridine hexafluorophosphate, and its structural formula is as follows:

[0060]

[0061] 【resolve resolution】

[0062] Add 25.42g of diethylamine, 70ml of 1,2-dichloroethane and 22.26g of triethylamine into a 500ml three-necked flask, place the system in an ice-salt bath and drop it below zero, and add 16.09g of 3- 48 ml of 1,2-dichloroethane solution of chloropropionyl chloride, the rate of addition is controlled to ensure that the reaction temperature is maintained within 10°C. After the dropwise addition, the reaction system was transferred to room temperature and reacted for 3 h.

[0063] Add 150ml of 1M hydrochloric acid solution dropwise to quench the experiment, let it stand, separate the phases, and keep the organic phase; the organic phase was successively washed with 150ml of 1M sodium hydroxide solution, 150ml of water, and 150ml of saturated saline, and finally dried with anhydrous sodium sulfat...

Embodiment 3

[0069] The extractant is 4-N, N, dimethyl-N'-bis(2-ethylhexyl)carbonylpropylpyridine hexafluorophosphate, and its structural formula is as follows:

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com