Method of non-noxious treatment of scrapped silicon dioxide etching solution

A silica and treatment method technology, which is applied in chemical instruments and methods, water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of high investment and operation costs, many treatment methods and equipment, and high treatment costs. Achieve the effect of eliminating secondary pollution, low treatment cost, and solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0026] Primary treatment:

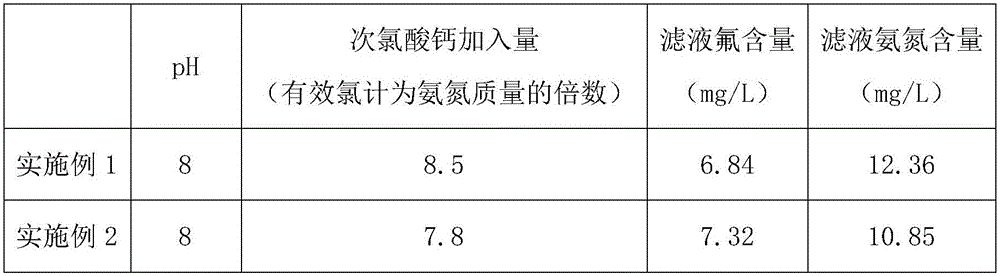

[0027] Add 1000mL of discarded silicon dioxide etching solution to a 2000mL three-necked bottle, the fluorine content of the waste solution is 33.5g / L, the ammonia nitrogen content is 19.6g / L, add 20% milk of lime to adjust the pH value to 10-13, the pH value If the amount of calcium is not enough after stabilization, add calcium chloride so that the amount of calcium added is 1.1-1.5 times of the theoretical amount; blow off the reaction with air for 1-3 hours, so that most of the ammonia nitrogen is removed in the form of ammonia , the combination of fluorine and calcium ions generates calcium fluoride precipitate, and the filter residue and filtrate are separated by suction filtration. The implementation conditions and treatment effects of the primary treatment are shown in Table 1.

[0028] The above-mentioned removed ammonia is absorbed with 10% sulfuric acid solution, and after the absorption solution is discarded, it is evaporated and crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com