Lithium ion battery non-aqueous electrolyte and lithium ion battery

A lithium-ion battery and non-aqueous electrolyte technology, applied in the field of lithium-ion battery non-aqueous electrolyte and lithium-ion battery, can solve the problems of high interface impedance, deteriorated low temperature performance, poor conductivity of passivation film, etc. Excellent low temperature performance and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of the lithium-ion battery in this example includes a positive electrode preparation step, a negative electrode preparation step, an electrolyte preparation step, a diaphragm preparation step and a battery assembly step. details as follows:

[0054] The positive electrode preparation step is: mix the positive electrode active material LiNi according to the mass ratio of 96.8:2.0:1.2 0.5 co 0.2 mn 0.3 o 2 , conductive carbon black and binder polyvinylidene fluoride are dispersed in N-methyl-2-pyrrolidone to obtain positive electrode slurry, and the positive electrode slurry is evenly coated on both sides of the aluminum foil, after drying, calendering and Vacuum drying, and welding aluminum lead wires with an ultrasonic welder to obtain a positive plate, the thickness of the plate is between 120-150 μm.

[0055] Negative electrode preparation steps are: mix graphite, conductive carbon black, binder styrene-butadiene rubber and carboxymethyl cel...

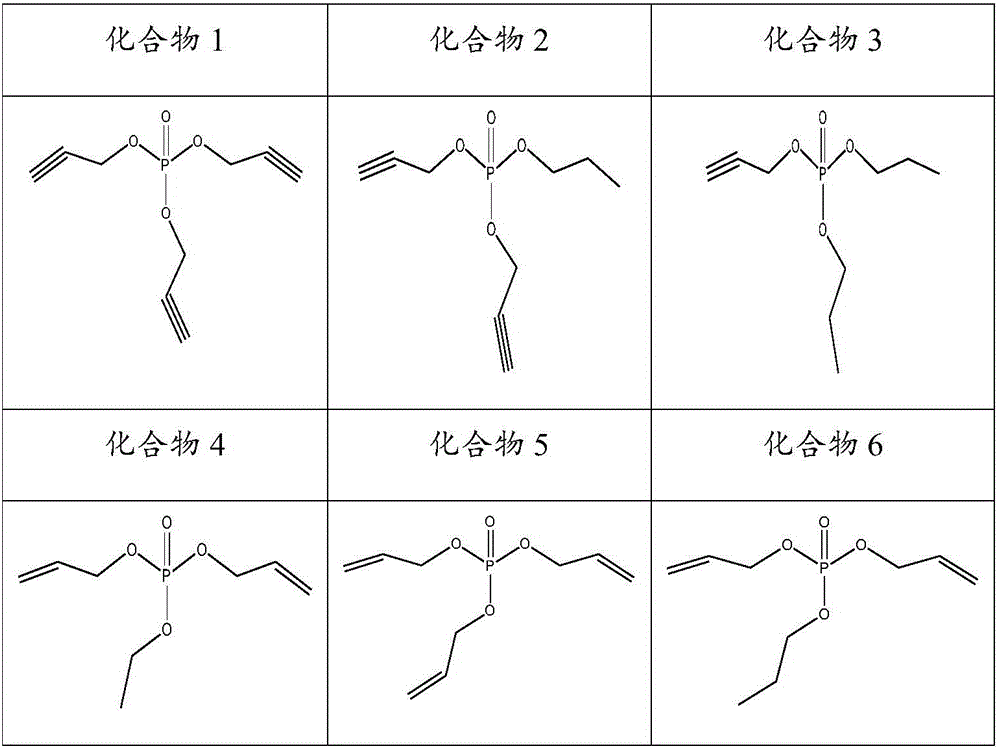

Embodiment 2-20

[0076] In Examples 2-20, except that the specific compounds of the sulfone compound and the unsaturated phosphoric acid ester compound, and the amount thereof are different, the others are the same as in Example 1. The specific compounds of each embodiment and their dosage are shown in Table 2, wherein the dosage is calculated according to the percentage of each substance accounting for the total weight of the non-aqueous electrolyte of the lithium-ion battery.

[0077] In addition, the present application has also designed 6 comparative examples, i.e. comparative examples 1-6. Similarly, compared with Example 1 or other examples, the 6 comparative examples are only different in the specific compound and dosage added, and the others are all Same as Example 1. The specific compounds and their dosages of each comparative example are shown in Table 2. Similarly, the dosages are calculated according to the percentage of the added substances in the total weight of the non-aqueous ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com