A high-temperature and high-salt heavy oil thermal recovery sewage degreaser and preparation method thereof

A heavy oil thermal recovery and degreaser technology, applied in mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. The preparation process is complex and other problems, so as to overcome the poor temperature and salt resistance, good dehydration performance and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Degreaser E 1 and its preparation method

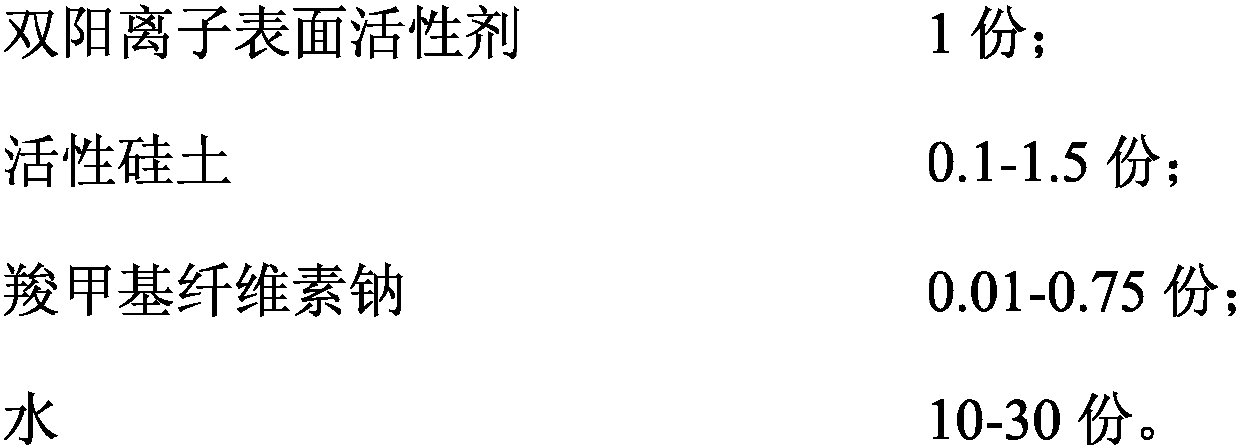

[0029] (1) Degreaser E 1 The composition and its components are as follows:

[0030]

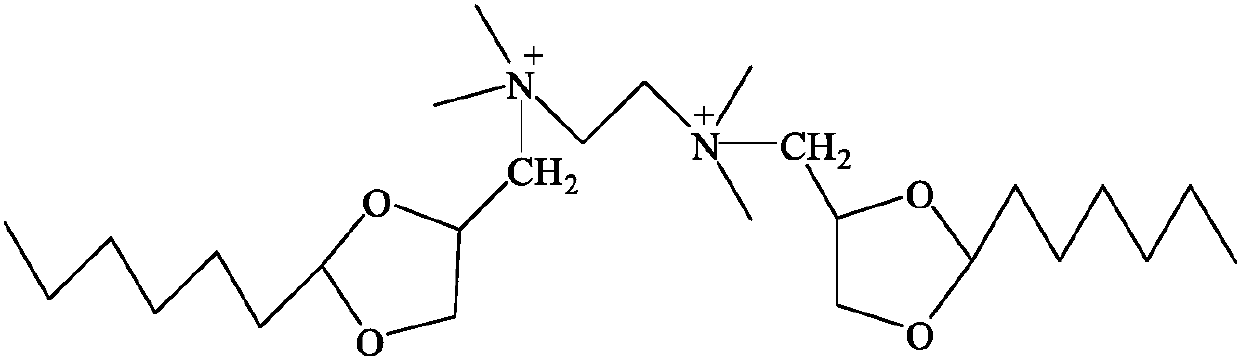

[0031] According to existing literature, the preparation method of described double cationic surfactant is as follows:

[0032]

[0033] (2) Degreaser E 1 The preparation method is as follows:

[0034] ①Put 10 parts of water in a beaker in a constant temperature water bath at 40°C, and slowly add 1 part of dicationic surfactant at a stirring rate of 350rpm. After the addition is complete, continue stirring for 30 minutes to obtain a mixed solution;

[0035] ② Adjust the temperature of the above mixed solution to 50°C. After the temperature is constant, slowly add 0.01 part of sodium carboxymethylcellulose at a stirring rate of 200 rpm, and continue stirring for 25 minutes to obtain a transparent solution;

[0036] ③Adjust the temperature of the above transparent solution to 35°C, adjust the stirring rate to 400rpm, an...

Embodiment 2

[0037] Embodiment 2: Degreaser E 2 and its preparation method

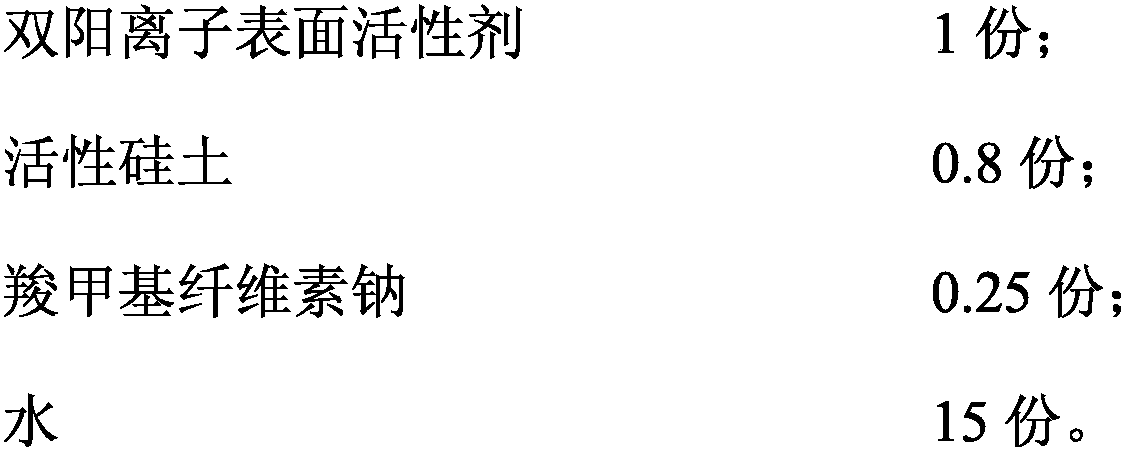

[0038] (1) Degreaser E 2 The composition and its components are as follows:

[0039]

[0040] According to existing literature, the preparation method of described double cationic surfactant is as follows:

[0041]

[0042]

[0043] (2) Degreaser E 2 The preparation method is as follows:

[0044] ①In a constant temperature water bath at 30°C, put 15 parts of water in a beaker, and slowly add 1 part of dicative surfactant at a stirring rate of 300rpm. After the addition is complete, continue stirring for 20 minutes to obtain a mixed solution;

[0045] ② Adjust the temperature of the above mixed solution to 52°C. After the temperature is constant, slowly add 0.25 parts of sodium carboxymethylcellulose at a stirring rate of 220 rpm, and continue stirring for 20 minutes to obtain a transparent solution;

[0046] ③Adjust the temperature of the above transparent solution to 38°C, adjust the stirring rate t...

Embodiment 3

[0047] Embodiment 3: Degreaser E 3 and its preparation method

[0048] (1) Degreaser E 3 The composition and its components are as follows:

[0049]

[0050] According to existing literature, the preparation method of described double cationic surfactant is as follows:

[0051]

[0052] (2) Degreaser E 3The preparation method is as follows:

[0053] ①In a constant temperature water bath at 50°C, put 30 parts of water in a beaker, and slowly add 1 part of dicative surfactant at a stirring rate of 400rpm. After the addition is complete, continue stirring for 25 minutes to obtain a mixed solution;

[0054] ② Adjust the temperature of the above mixed solution to 55°C. After the temperature is constant, slowly add 0.75 parts of sodium carboxymethylcellulose at a stirring rate of 250 rpm, and continue stirring for 30 minutes to obtain a transparent solution;

[0055] ③Adjust the temperature of the above transparent solution to 40°C, adjust the stirring rate to 600rpm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com