Integrated Soil Remediation Photocatalytic Reactor

A photocatalytic reactor and soil remediation technology, applied in the field of integrated soil remediation photocatalytic reactors, can solve the problems of insufficient contact between photocatalysts and soil pollutants, difficult separation of soil particles, harsh photocatalytic reaction conditions, etc. To achieve efficient and stable processing effect, avoid a large amount of loss, and achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

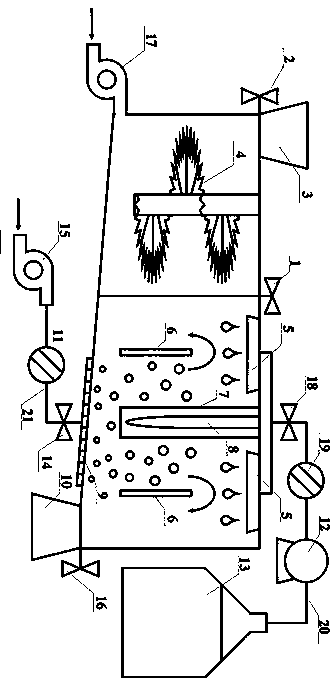

[0032] Such as figure 1 As shown, the integrated soil repair photocatalytic reactor includes a reactor shell, a cutter 4, a spraying device, two deflectors 6, an LED light 8 and an aeration device; the reactor shell includes a soil crushing chamber and a three-phase cycle photocatalytic degradation chamber; two reaction chambers are arranged in the housing, the soil inlet is connected to the soil crushing chamber, and the soil outlet is connected to the three-phase cycle photocatalytic degradation chamber.

[0033] The soil crushing chamber is connected to the three-phase cycle photocatalytic degradation chamber, and the cutter 4 is rotatably connected to the top wall of the soil crushing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com