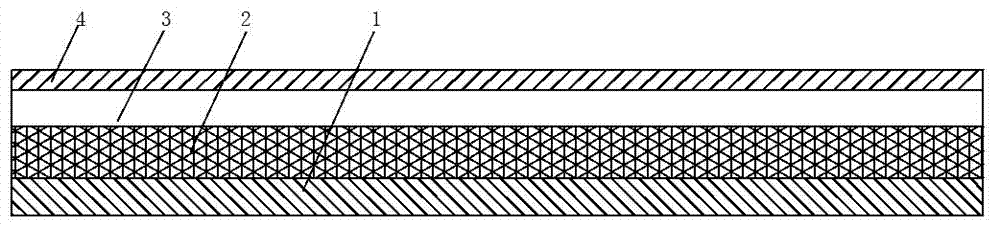

Antibacterial, mildew-proof, corrosion-resistant, fire-proof, high-pressure decorative board and production method thereof

An antibacterial, anti-mildew, and corrosion-resistant technology, applied in the field of decorative panels, can solve problems such as high compressive strength, brittle fracture, tensile strength, bending strength, and poor impact resistance, and achieve good surface corrosion resistance and durability. High impact strength and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 of the production method of the antibacterial, mildew-proof, corrosion-resistant, fire-proof and high-pressure decorative board of the present invention includes the following steps: (1) preparing an impregnated flame-retardant substrate blank;

[0056] First prepare the alcohol-soluble phenolic resin for impregnating the glass fiber mat, and then add Al with a diameter of 1-3um according to 40% of the mass of the alcohol-soluble phenolic resin 2 o 3 Powder, the final selection is 80g / m 2 The glass fiber mat is impregnated with phenolic resin and dried, glue amount: 500%, volatile matter: 6.7%; cut according to the specified size requirements and select the appropriate number of layers according to the thickness requirements to obtain an impregnated flame-retardant substrate blank;

[0057] (2) Preparation of impregnated flame retardant buffer paper;

[0058] First prepare the thermosetting alcohol-soluble phenolic resin for impregnating kraft paper, then...

Embodiment 2

[0066] Embodiment 2 of the production method of the antibacterial, mildew-proof, corrosion-resistant, fire-proof and high-pressure decorative board of the present invention includes the following steps: (1) preparing an impregnated flame-retardant substrate blank;

[0067] First prepare the alcohol-soluble phenolic resin for impregnating the glass fiber mat, and then add Al with a diameter of 1-3um according to 70% of the mass of the alcohol-soluble phenolic resin 2 o 3 Powder, the final selection is 120g / m 2 The glass fiber mat is impregnated with phenolic resin and dried, the glue content: 400%, volatile matter: 7.5%; cut according to the specified size requirements and select the appropriate number of layers according to the thickness requirements to obtain the impregnated flame-retardant substrate blank;

[0068] (2) Preparation of impregnated flame retardant buffer paper;

[0069] First prepare the thermosetting alcohol-soluble phenolic resin for impregnating kraft pape...

Embodiment 3

[0077] Embodiment 3 of the production method of the antibacterial, mildew-proof, corrosion-resistant, fire-proof and high-pressure decorative board of the present invention includes the following steps: (1) preparing an impregnated flame-retardant substrate blank;

[0078] First prepare the alcohol-soluble phenolic resin for impregnating the glass fiber mat, and then add Al with a diameter of 1-3um according to 110% of the mass of the alcohol-soluble phenolic resin 2 o 3 Powder, the final selection is 50g / m 2 The glass fiber mat is impregnated with phenolic resin and dried, glue amount: 300%, volatile matter: 6.0%; cut according to the specified size requirements and select the appropriate number of layers according to the thickness requirements to obtain an impregnated flame-retardant substrate blank;

[0079] (2) Preparation of impregnated flame retardant buffer paper;

[0080] First prepare the thermosetting alcohol-soluble phenolic resin for impregnating kraft paper, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com