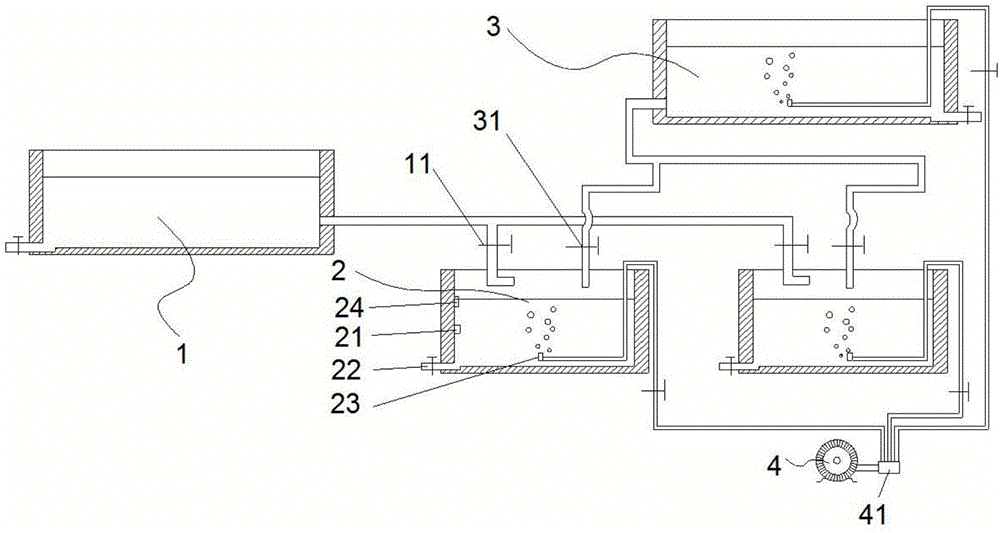

Self-self-purification type breeding device and self-purification method thereof

A technology for aquaculture ponds and aquaculture water, applied in chemical instruments and methods, special compound water treatment, water/sludge/sewage treatment, etc., can solve problems such as loss of bait and nutrients, pollution of aquaculture ponds, and increase in aquaculture costs. Achieve the effect of improving self-purification ability and increasing dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

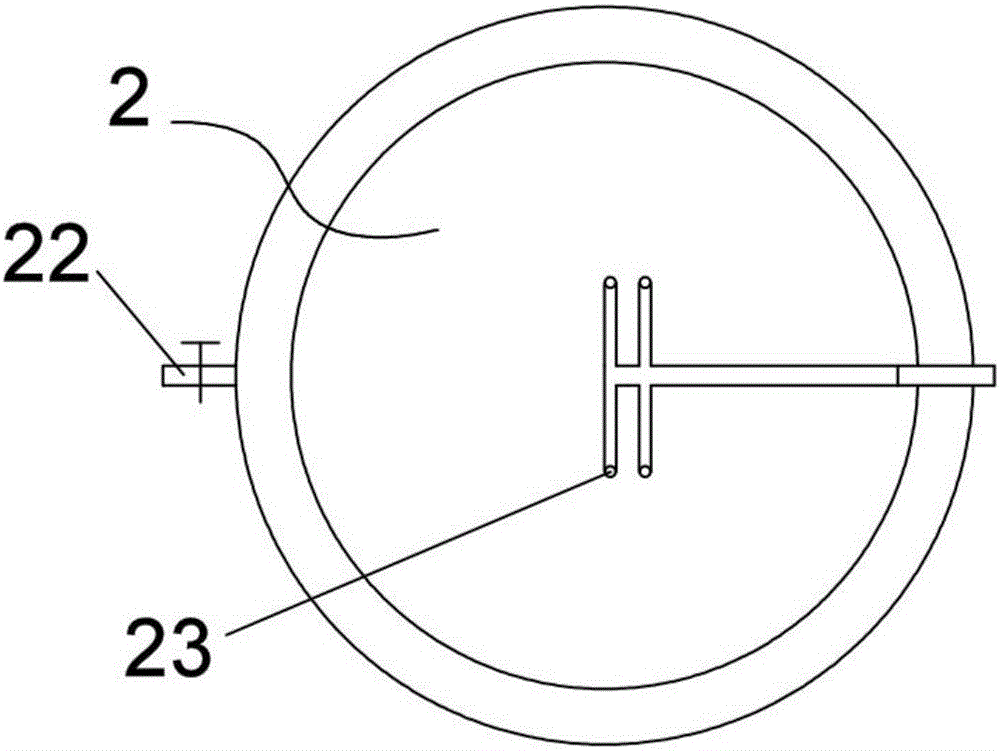

Embodiment 1

[0035] A self-cleaning method for a self-cleaning breeding device, comprising the following steps:

[0036] a) Microbial mixing: mix bacillus, nitrifying bacteria, yeast, lactic acid bacteria, acetic acid bacteria, rhodospirilla and sewage bacteria according to the volume ratio of 1:1:0.5:0.2:0.2:0.1:0.1 to prepare the mixture A; Mix chlorella, Scenedesmus and diatoms at a volume ratio of 1:1:1 to make a mixture B;

[0037] b) Microbial inoculation: the reservoir transports water to the culture tank through pipelines. After the water transfer is completed, add the mixed solution A according to the volume ratio of the water in the culture tank and the mixed solution A at a ratio of 1000:3. The volume ratio of the water and the mixed solution B is 1000:1 and added to the mixed solution B;

[0038] c) Microbial culture in the culture pond: measure the nitrogen content of the culture water in the culture pond, add glucose or sucrose according to 5 times the nitrogen content, adjust...

Embodiment 2

[0042] A self-cleaning method for a self-cleaning breeding device, comprising the following steps:

[0043] a) Microbial mixing: mix bacillus, nitrifying bacteria, yeast, lactic acid bacteria, acetic acid bacteria, rhodospirilla and sewage bacteria according to the volume ratio of 3:1:1:0.2:0.2:0.1:0.1 to prepare the mixture A; Mix chlorella, Scenedesmus and diatoms at a volume ratio of 2:1:1 to make a mixture B;

[0044] b) Microbial inoculation: the reservoir transports water to the culture tank through the pipeline. After the water transfer is completed, add the mixed solution A according to the volume ratio of the water in the culture tank and the mixed solution A at a ratio of 1000:1. The volume ratio of water and mixed solution B is 1000:5 and added to mixed solution B;

[0045] c) Microbial culture in the culture pond: measure the nitrogen content of the culture water in the culture pond, add glucose or sucrose according to 20 times the nitrogen content, adjust the tem...

Embodiment 3

[0049] A self-cleaning method for a self-cleaning breeding device, comprising the following steps:

[0050] a) Microbial mixing: mix bacillus, nitrifying bacteria, yeast, lactic acid bacteria, acetic acid bacteria, rhodospirilla and sewage bacteria according to the volume ratio of 2:1:0.8:0.2:0.2:0.1:0.1 to prepare the mixture A; Mix chlorella, Scenedesmus and diatoms at a volume ratio of 1.5:1:1 to make a mixture B;

[0051] b) Microbial inoculation: the water storage tank transports the water to the culture pond through the pipeline. The volume ratio of the water and the mixed solution B is 1000:3 and added to the mixed solution B;

[0052] c) Microbial culture in the culture pond: measure the nitrogen content of the culture water in the culture pond, add glucose or sucrose according to 18 times the nitrogen content, adjust the temperature of the culture pond to 28°C, adjust the pH of the culture water to 7, and start the aeration pump Feed oxygen into the culture pond for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com