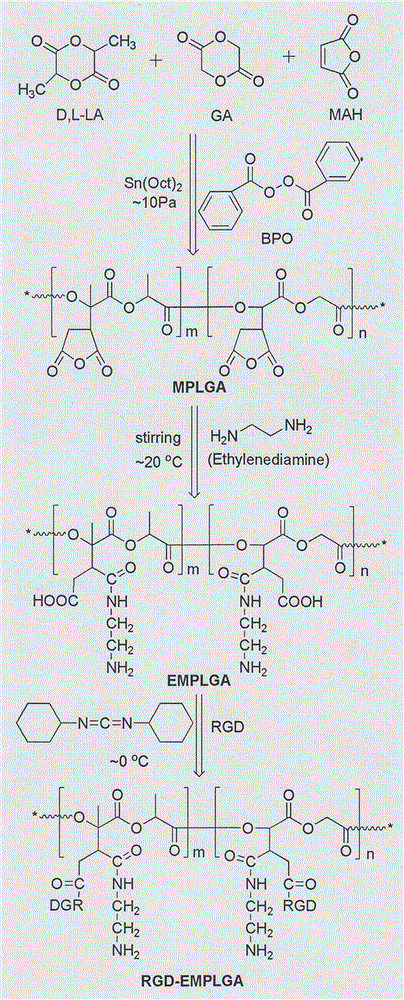

Preparation method of ethylenediamine and RGD polypeptide modified MPLGA with high anhydride content

A technology with high acid anhydride and ethylenediamine is applied in the field of preparation of MPLGA with high anhydride content modified by ethylenediamine and RGD polypeptide, which can solve problems such as uneven distribution, loss of biological functions, and easy dedifferentiation of cells, and achieve expansion Effects of regulating range, improving cell affinity, and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Put 73 g of D,L-lactide, 27 g of glycolide and 5 g of maleic anhydride into an ampoule, then add 0.2 g of benzoyl peroxide (BPO) as an initiator, and 0.01 g of stannous octoate as a catalyst , vacuum dried for 12h. After drying, take it out, evacuate it with a diffusion pump for 1 h, seal the tube at a vacuum degree of 7.0 Pa, and react the sealed ampoule in a constant temperature drying oven at 130°C for 36 h. The crude product MPLGA was dissolved in chloroform and purified by precipitation with excess ethanol. The resulting MPLGA molecular weight M w =27850, M w / M n =1.65, the maleic anhydride graft rate is 9.2%.

[0028] Dissolve 5 g of purified MPLGA in 8 mL of chloroform to prepare a 30wt% MPLGA solution in chloroform, and mix equal volumes of ethylenediamine and chloroform to prepare a 38wt% ethylenediamine solution in chloroform. Add the chloroform of MPLGA into a three-necked flask equipped with a stirrer and a thermometer, add 2 mL of ethylenediamine in ...

Embodiment 2

[0031] Put 75 g of D,L-lactide, 25 g of glycolide and 8 g of maleic anhydride into an ampoule, then add 0.3 g of benzoyl peroxide (BPO) as an initiator, and 0.02 g of stannous octoate as a catalyst , vacuum dried for 12h. After drying, take it out, evacuate it with a diffusion pump for 1 h, seal the tube at a vacuum degree of 6.0 Pa, and react the sealed ampoule in a constant temperature drying oven at 140 °C for 48 h. The crude product MPLGA was dissolved in chloroform and purified by precipitation with excess ethanol. The resulting MPLGA molecular weight M w =30125, Mw / M n =1.60, maleic anhydride graft rate, 7.9%.

[0032] Dissolve 5g of MPLGA in 10mL of chloroform to prepare 25wt% MPLGA in chloroform, and mix equal volumes of ethylenediamine and chloroform to prepare 38wt% ethylenediamine in chloroform. Add the chloroform of MPLGA into a three-necked flask equipped with a stirrer and a thermometer, add 2 mL of ethylenediamine in chloroform solution dropwise under stir...

Embodiment 3

[0035] Put 70 g of D,L-lactide, 25 g of glycolide and 6 g of maleic anhydride into an ampoule, then add 0.2 g of benzoyl peroxide (BPO) as an initiator, and 0.03 g of stannous octoate as a catalyst , vacuum dried for 12h. After drying, take it out, evacuate it with a diffusion pump for 1 h, seal the tube at a vacuum degree of 8.0 Pa, and react the sealed ampoule in a constant temperature drying oven at 130°C for 60 h. The crude product MPLGA was dissolved in chloroform and purified by precipitation with excess ethanol. The resulting MPLGA molecular weight M w =28455, M w / M n =1.72, the maleic anhydride graft rate is 7.4%.

[0036] Dissolve 10g of MPLGA in 16mL of chloroform to prepare a 30wt% MPLGA solution in chloroform, and mix equal volumes of ethylenediamine and chloroform to prepare a 38wt% ethylenediamine solution in chloroform. Add the chloroform of MPLGA into a three-necked flask equipped with a stirrer and a thermometer, add 2 mL of ethylenediamine in chlorofor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com