Method for preparing diamond vacuum window with self-supporting frame by virtue of mask method

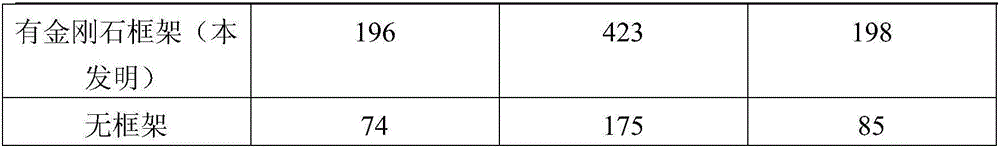

A self-supporting, diamond technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of thermal stress cracking of diamond self-supporting window, low mechanical strength of diamond film, inability to withstand external pressure, etc. problem, to achieve the effect of good air tightness, good thermal stability and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

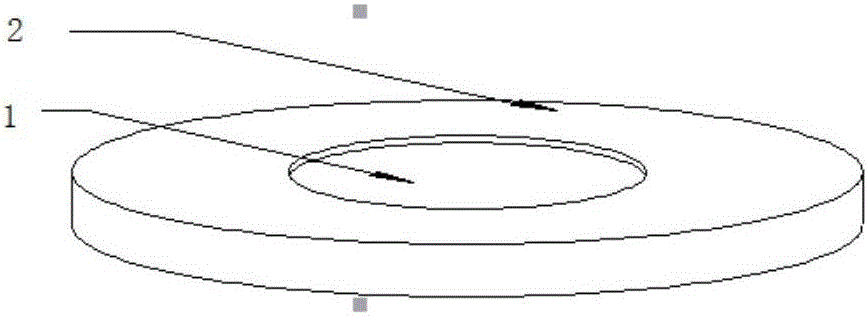

Image

Examples

Embodiment 1

[0026] The nano-diamond film has a thickness of 4 μm and a diameter of 10 mm; a molybdenum sheet (molybdenum disc) has a thickness of 0.2 mm and a diameter of 6 mm;

[0027] In the first step, the nano-diamond film supported by the silicon substrate and the molybdenum sheet are ultrasonically cleaned with acetone and ethanol (alcohol) to remove surface impurities (ultrasonic frequency 40000Hz, power 500W), and dried for use;

[0028] In the second step, the molybdenum sheet cleaned in the first step is placed in the middle of the surface of the nano-diamond film to obtain a sample; then the sample is placed on the substrate stage in the reaction chamber of the microwave plasma chemical vapor deposition device;

[0029] The third step is to seal the reaction chamber, turn on the vacuum pump to evacuate the reaction chamber (cavity), and feed 200 sccm of hydrogen after the vacuum degree drops to the standard vacuum degree (below 1Pa);

[0030] The fourth step is to turn on the m...

Embodiment 2

[0034] The nano-diamond film has a thickness of 8 μm and a diameter of 12 mm, and a molybdenum sheet (molybdenum disc) has a thickness of 0.5 mm and a diameter of 7 mm;

[0035] In the first step, the nano-diamond film supported by the silicon substrate and the molybdenum sheet are ultrasonically cleaned with acetone and ethanol solvent (alcohol) respectively (the frequency of the ultrasonic wave is 40000Hz, and the power is 500W) to remove surface impurities, and then dried for use;

[0036] In the second step, the molybdenum sheet cleaned in the first step is placed in the middle of the surface of the nano-diamond film to obtain a sample; then the sample is placed on the substrate stage in the reaction chamber of the microwave plasma chemical vapor deposition device;

[0037] The third step is to seal the reaction chamber, turn on the vacuum pump to evacuate the reaction chamber (cavity), and feed 200 sccm of hydrogen after the vacuum degree drops to the standard vacuum degre...

Embodiment 3

[0041]The nano-diamond film has a thickness of 5 μm and a diameter of 9 mm, and a molybdenum sheet (molybdenum disc) has a thickness of 0.3 mm and a diameter of 6 mm;

[0042] In the first step, the nano-diamond film and the molybdenum sheet supported by the silicon substrate are ultrasonically cleaned with acetone and ethanol solvent (alcohol) to remove surface impurities (ultrasonic power is 200-500W), and dried for use;

[0043] In the second step, the molybdenum sheet cleaned in the first step is placed in the middle of the surface of the nano-diamond film to obtain a sample; then the sample is placed on the substrate stage in the reaction chamber of the microwave plasma chemical vapor deposition device;

[0044] The third step is to seal the reaction chamber, turn on the vacuum pump to evacuate the reaction chamber (cavity), and feed 200 sccm of hydrogen after the vacuum degree drops to the standard vacuum degree (below 1Pa);

[0045] The fourth step is to turn on the mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com