A kind of uio-66-nh2 composite catalyst supporting transition metal copper and its preparation method and application

A technology of uio-66-nh2 and composite catalysts, which is applied in the direction of physical/chemical process catalysts, catalytic reactions, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as thinness, and achieve cost reduction and economic reduction The effect of less cost and usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Metal Organic Framework UiO-66-NH 2 preparation of

[0040] Concrete preparation steps are as follows:

[0041] Take ZrCl 4 (139.9mg, 0.60mmol) and CH 3 COOH (538μL, 9.4mmol) was dissolved in 15mL DMF solution, sonicated for 30min, after the solution was clarified, 2-aminoterephthalic acid (108.6mg, 0.60mmol) was added, and sonicated for 10min, the solution was transferred to an autoclave, Heating at 120°C for 24 hours, after the reaction is complete, centrifuge, wash and activate to obtain UiO-66-NH 2 Metal organic framework material 95.0mg, yield 89.7%.

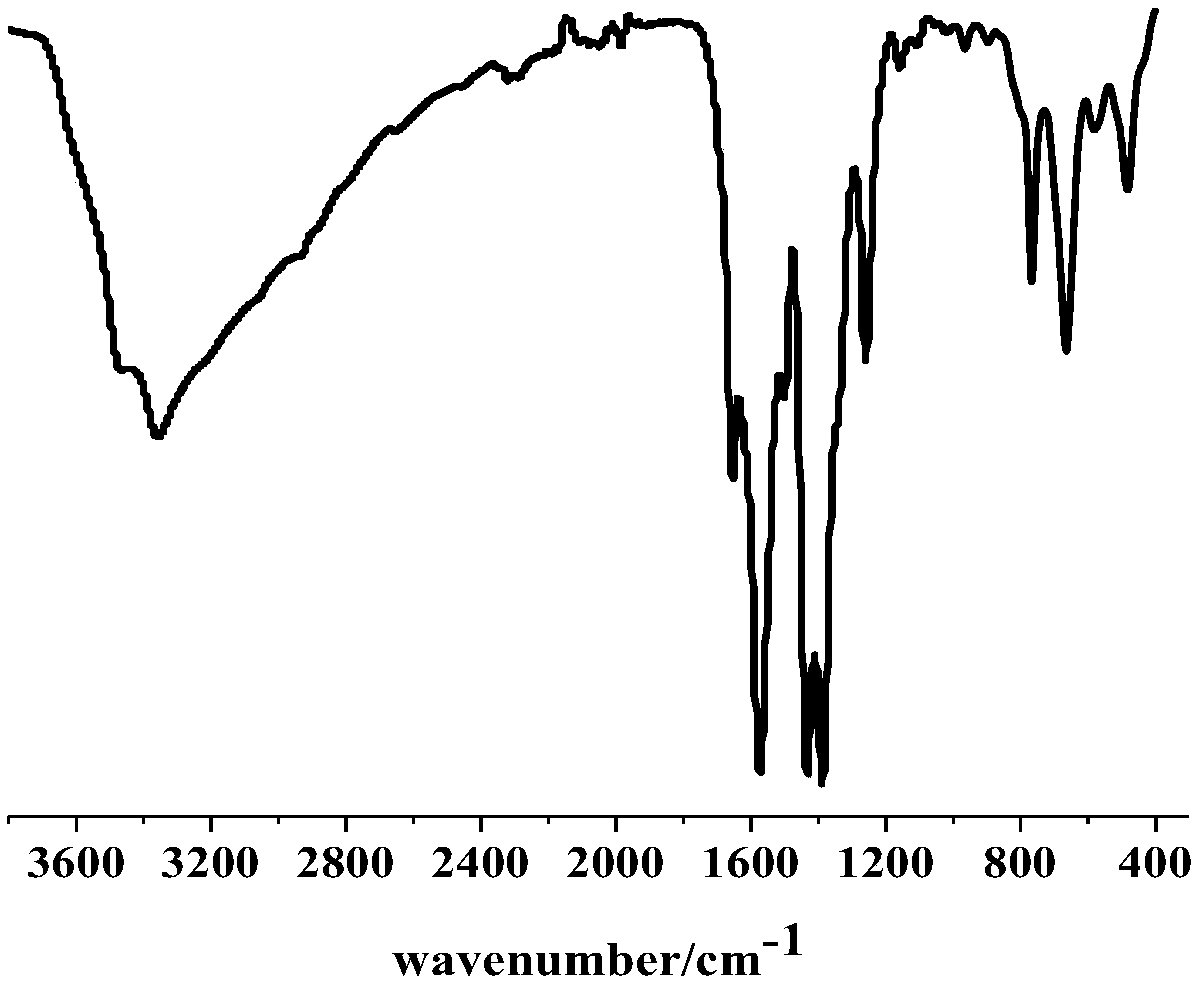

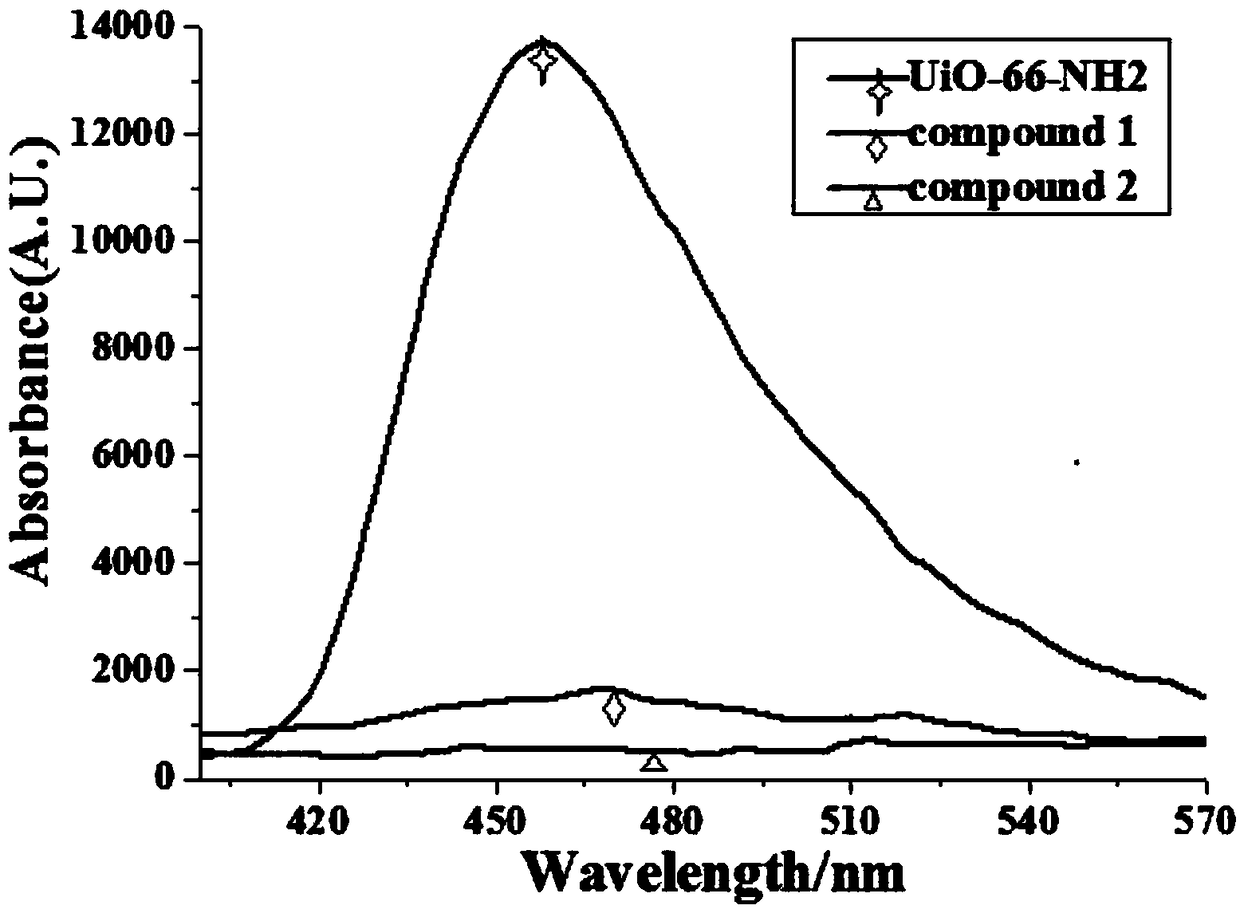

[0042] For the UiO-66-NH prepared in this example 2 For characterization, IR, fluorescence such as figure 1 , 2 shown.

Embodiment 2

[0043] Example 2: Cu(Ⅱ)@UiO-66-NH 2 preparation of

[0044] Take UiO-66-NH 2 10.0 mg, placed in 2 mL of Cu(OAc) with a concentration of 0.02 mol / L 2 After soaking in the ethanol solution for 1 hour, centrifuge, soak and wash with ethanol three times, and dry at 80°C for 12 hours to obtain Cu(Ⅱ)@UiO-66-NH 2

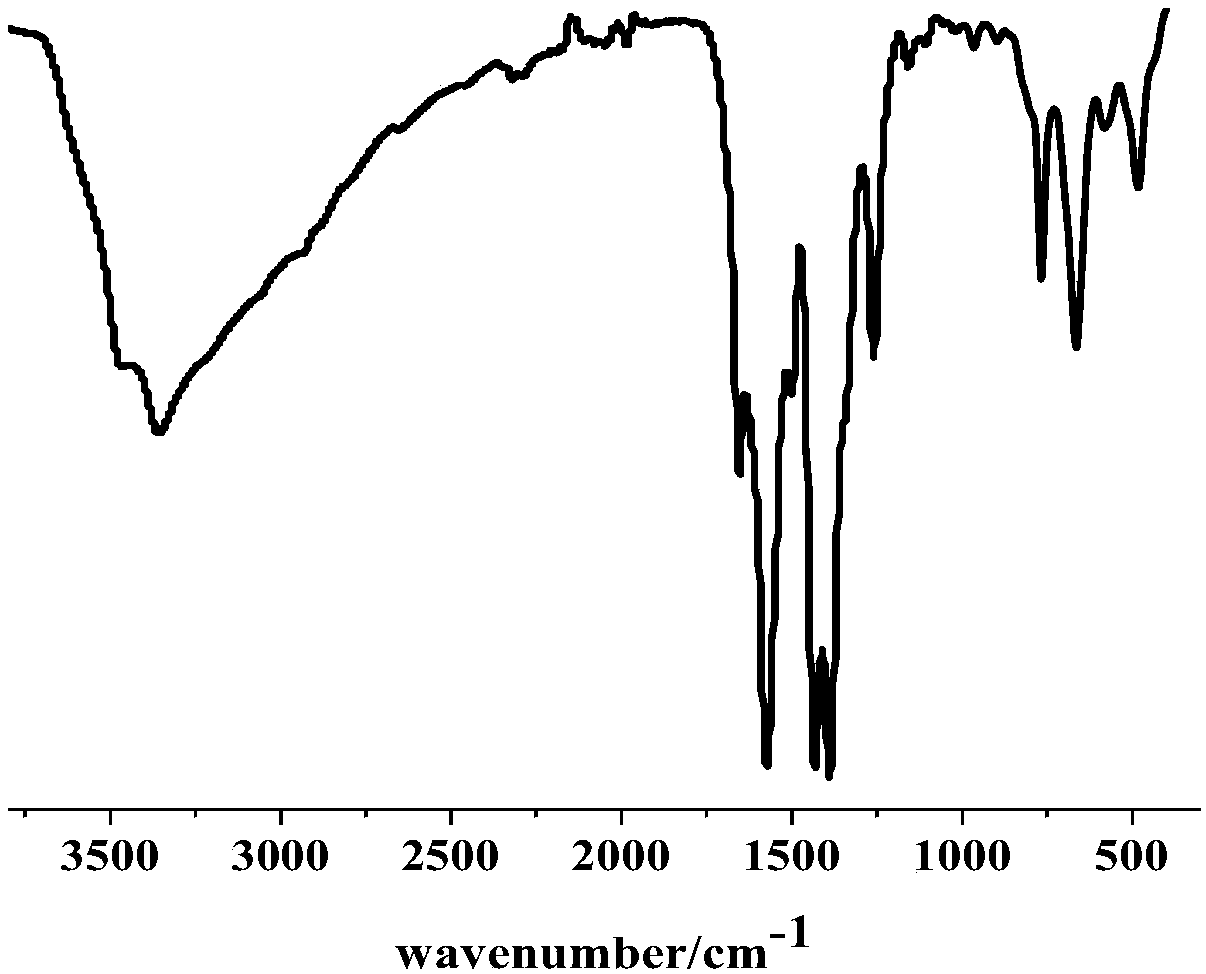

[0045] Characterization of Cu(Ⅱ)@UiO-66-NH by fluorescence, IR, XPS and SEM 2 , see the results respectively figure 2 , 3 , 4 and 5.

Embodiment 3

[0046] Example 3: Cu(0)@UiO-66-NH 2 Preparation of composite catalyst

[0047] The Cu(Ⅱ)@UiO-66-NH prepared in Example 2 2 N 2 Add 10mL of ethanol and 50mL of dichloromethane under protection, stir to form a uniform turbid liquid, maintain the reaction system at 0°C and add 2mL of NaBH with a concentration of 7.5mg / mL dropwise 4 aqueous solution, after the dropwise addition, the ice bath was removed, the reaction system was gradually raised to room temperature, continued to stir for 0.5 hours, and centrifuged to obtain Cu(0)@UiO-66-NH 2 .

[0048] Characterization of Cu(0)@UiO-66-NH by fluorescence, IR, XPS, SEM and TEM 2 , see the results respectively figure 2 , 6 , 7, 8 and 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com