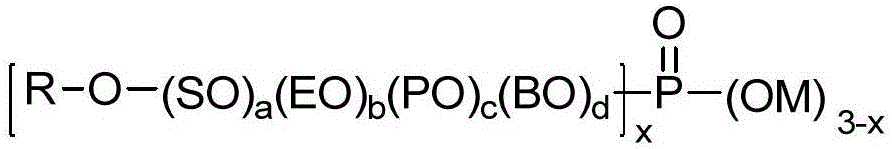

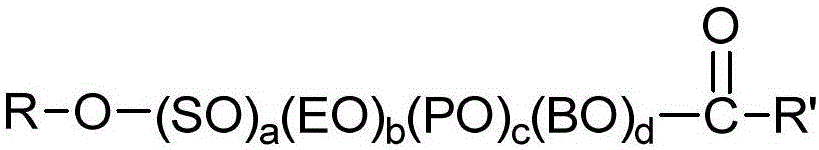

Environmentally-friendly pesticide wetting dispersant, modified dispersant, and preparation method and application of pesticide wetting dispersant

A technology for wetting and dispersing agents and environmentally friendly pesticides, applied in the field of wetting and dispersing agents for environmentally friendly pesticides and its preparation, can solve problems such as short alkyl chains, no sulfonation of terminal hydroxyl groups, and inability to achieve particle surface anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 30.4g (0.1mol) cardanol and 0.2g homogeneous gold complex AuL 1 (L 1 =PPh 3 Cl phosphine-containing ligand) is placed in the reactor. After carefully purging with ultrapure nitrogen, it was heated to 120° C., and 24.0 g (0.2 mol) of styrene oxide were added within 1 h. After reacting for 2 hours, the remaining residual styrene oxide content was determined by gas chromatography, which was less than 0.1 wt%. 44.0 g (1 mole) of ethylene oxide were metered into the reactor at a temperature not exceeding 130° C. and a pressure not exceeding 6 bar inside the reactor. After the addition of ethylene oxide is completed, the pressure change of the test reactor is used to indicate whether the reaction is completed or not. After the reaction is completed, the internal temperature of the reactor is maintained at 125°C. Finally, the temperature was lowered to 80°C to 90°C, and unreacted residual monomers were removed under reduced pressure. Neutralize with phosphoric acid, then ...

Embodiment 2

[0065] 14.4 g (0.1 mol) of isononanol and 0.35 g (0.005 mol) of potassium methoxide were placed in the reactor. After careful purging with ultrapure nitrogen, it was heated to 110° C. and 12.0 g (0.1 mol) of styrene oxide were added within 1 hour. After reacting for 2 hours, the remaining residual styrene oxide content was determined by gas chromatography, and it was less than 0.1 wt%. 35.0 g (0.8 mol) of ethylene oxide were metered into the reactor at a temperature not exceeding 120° C. and a pressure not exceeding 6 bar within the reactor. After the addition of ethylene oxide is completed, the pressure change of the test reactor is used to indicate whether the reaction is over. After the reaction is over, the internal temperature of the reactor is maintained at 115°C. Finally, purging with nitrogen gas, lowering the temperature to 80° C. to 90° C., and removing unreacted residual monomers under reduced pressure. Neutralize with phosphoric acid, then distill off water, and ...

Embodiment 3

[0068] 17.2g (0.1mol) decanoic acid and 0.2g boron trifluoride etherate complex BF 3 ·Et 2 O is placed in the reactor. After careful purging with ultrapure nitrogen, it was heated to 120° C. and 24.0 g (0.2 mol) of styrene oxide were added within 1 hour. After reacting for 2 hours, the remaining residual styrene oxide content was determined by gas chromatography, and it was less than 0.1 wt%. 39.6 g (0.9 mol) of ethylene oxide were metered into the reactor at a temperature not exceeding 130° C. and a pressure not exceeding 6 bar within the reactor. After the addition of ethylene oxide is completed, the pressure change of the test reactor is used to indicate whether the reaction is complete or not, and 11.6g (0.2 moles) of propylene oxide is continuously added to the reactor, and the temperature is lowered to 80°C- 90°C, remove unreacted residual monomers under reduced pressure. Recorded as PAO3.

[0069]Add the above-mentioned 0.1 mole of polyalkylene oxide PAO3 (hydroxyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical micelle concentration (mass) | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com