Method for preparing copper tungstate photo-anode film

A copper tungstate and photoanode technology, which is applied in photovoltaic power generation, photosensitive equipment, electrolytic capacitors, etc., can solve the problem of low conversion efficiency from solar energy to hydrogen energy, and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0020] The preparation method of copper tungstate photoanode comprises the steps:

[0021] (1) at first prepare the organic solution that contains copper, tin element, be that copper nitrate trihydrate is dissolved in ethylene glycol methyl ether respectively, and concentration is 0.05mol / L; Dihydrate tin protochloride is dissolved in ethylene glycol methyl ether, concentration 0.05mol / L;

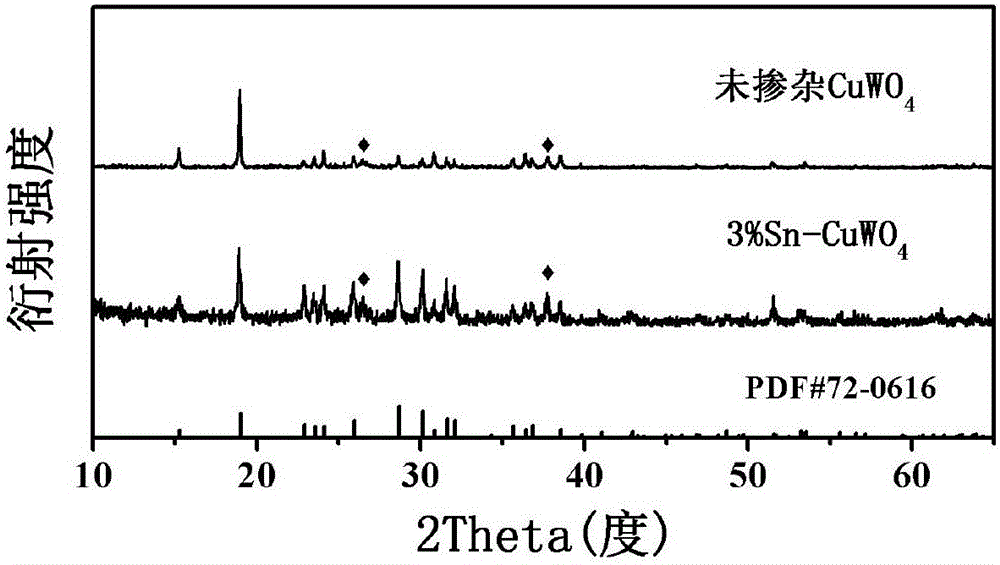

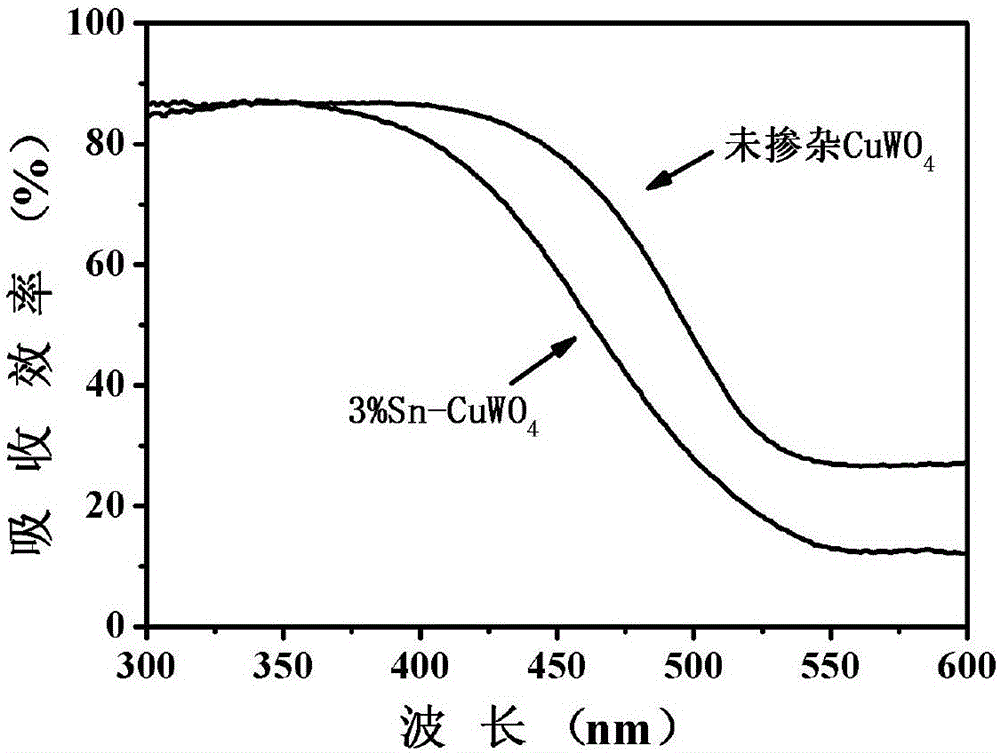

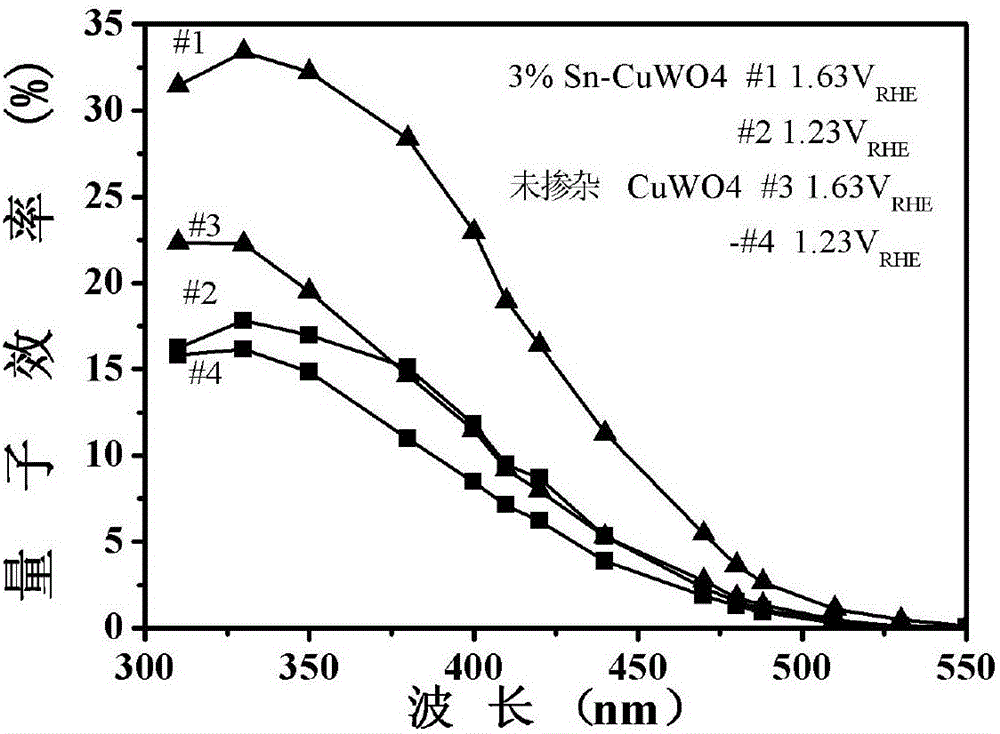

[0022] (2) Get (5-X) ml and the copper and tin solution configured in the step (1) of X ml respectively, mix to uniform, wherein when X=0.15, the tin-doped copper tungstate photoanode has the best performance;

[0023] (3) Add an equimolar amount of ammonium metatungstate, then add 0.1-0.7ml of concentrated nitric acid and 10-100mg of ammonium nitrate, stir the solution until it becomes clear, and obtain the precursor solution. The volume of concentrated nitric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com