Comprehensive method for all-around improvement of quality of reconstituted tobacco

A technology of reconstituted tobacco leaves and comprehensive methods, which is applied in the field of tobacco industry, can solve the problems of reducing the pH value of flue gas, etc., and achieve the effects of reducing nicotine content, reducing rough taste, mild process conditions and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

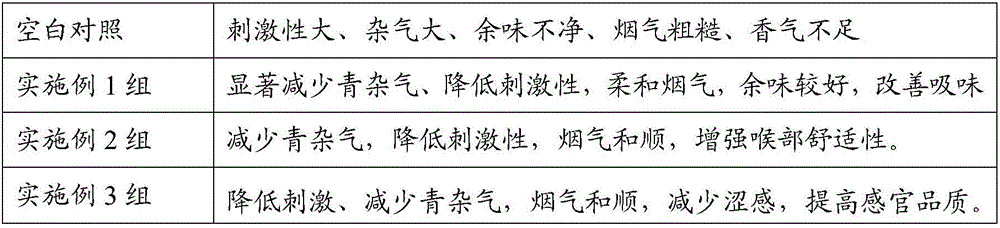

Examples

Embodiment 1

[0023] The present invention provides a comprehensive method to comprehensively improve the quality of reconstituted tobacco leaves, the preparation of which comprises the following steps:

[0024] (1) Composite fermentation: in the extraction process of reconstituted tobacco leaves, with the amount of 0.14% of the mass ratio of reconstituted tobacco leaves, Aspergillus niger feruloesterase, soil lignin peroxidase (S-Lip), Bacillus licheniformis Powder and freeze-dried lactic acid bacteria powder are added to the aqueous solution of reconstituted tobacco leaves in a certain proportion, mixed evenly, adjusted to pH 4.5, and fermented for 3 hours at 35°C;

[0025] The Aspergillus niger ferulic acid esterase is food grade, and the enzyme activity is 1000u / g, and the mass ratio accounting for the reconstituted tobacco leaves is 0.05%; soil lignin peroxidase (S-Lip), food grade, the enzyme activity is 3000u / g g, accounting for 0.05% of the mass ratio of reconstituted tobacco leaves...

Embodiment 2

[0032] The present invention provides a comprehensive method to comprehensively improve the quality of reconstituted tobacco leaves, the preparation of which comprises the following steps:

[0033] (1) Composite fermentation: in the extraction process of reconstituted tobacco leaves, with the amount of 0.2% of the mass ratio of reconstituted tobacco leaves, Aspergillus niger ferulic acid esterase, soil lignin peroxidase (S-Lip), Bacillus licheniformis Powder and freeze-dried lactic acid bacteria powder are added to the reconstituted tobacco leaf aqueous solution in a certain proportion, mixed evenly, adjusted to pH 5.0, and fermented for 4 hours at 40°C;

[0034] The Aspergillus niger ferulic esterase is food-grade, with an enzyme activity of 500u / g, accounting for 0.08% of the mass ratio of reconstituted tobacco leaves; soil lignin peroxidase (S-Lip), food-grade, with an enzyme activity of 1000u / g g, accounting for 0.05% of the mass ratio of reconstituted tobacco leaves; Baci...

Embodiment 3

[0041] The present invention provides a comprehensive method to comprehensively improve the quality of reconstituted tobacco leaves, the preparation of which comprises the following steps:

[0042] (1) Composite fermentation: in the extraction process of reconstituted tobacco leaves, with the amount of 0.3% of the mass ratio of reconstituted tobacco leaves, Aspergillus niger ferulic acid esterase, soil lignin peroxidase (S-Lip), Bacillus licheniformis Powder and freeze-dried lactic acid bacteria powder are added to the reconstituted tobacco leaf aqueous solution in a certain proportion, mixed evenly, adjusted to pH 5.5, and fermented for 5 hours at 37°C;

[0043] The Aspergillus niger ferulic acid esterase is food grade, with an enzyme activity of 800u / g, accounting for 0.1% of the mass ratio of reconstituted tobacco leaves; soil lignin peroxidase (S-Lip), food grade, with an enzyme activity of 1000u / g g, accounting for 0.1% of the mass ratio of reconstituted tobacco leaves; B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com