Preparation method of low-expansion long-circulating natural graphite

A natural graphite, long-cycle technology, applied in the direction of graphite, etc., can solve the problems of unsuitable for high-current charging and discharging, long diffusion path of lithium ions, poor fast charging and discharging performance, etc., and achieve good high-current charging and discharging performance and excellent comprehensive performance , The effect of stable product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

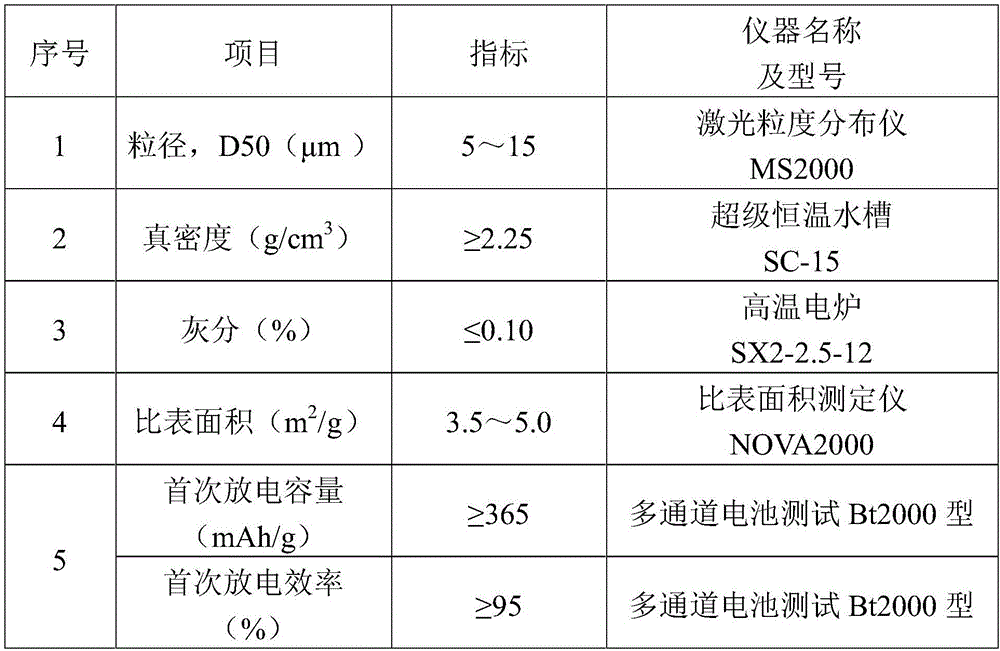

Embodiment 1

[0032] Microcrystalline graphite powder: D50 is 9.1μm, 200kg;

[0033] Graphitizable binder: petroleum pitch powder below 5μm, 60kg;

[0034] Under stirring, alternately add microcrystalline graphite powder and petroleum pitch powder into the mixing pot and mix. Under the protection of nitrogen, heat treatment at a low temperature of 500 ° C for 16 hours, then cool the reaction product to room temperature, and then conduct high-temperature treatment of graphitization at 2800 ° C for 36 hours, mix and sieve, and obtain particles with a particle size D50 of 10.8μm low-expansion long-cycle natural graphite has a half-cell capacity of 367.5mAh / g and an initial efficiency of 95.8%.

Embodiment 2

[0036] Microcrystalline graphite powder: D50 is 9.5μm, 200kg;

[0037] Graphitizable binder: petroleum pitch powder below 5μm, 20kg;

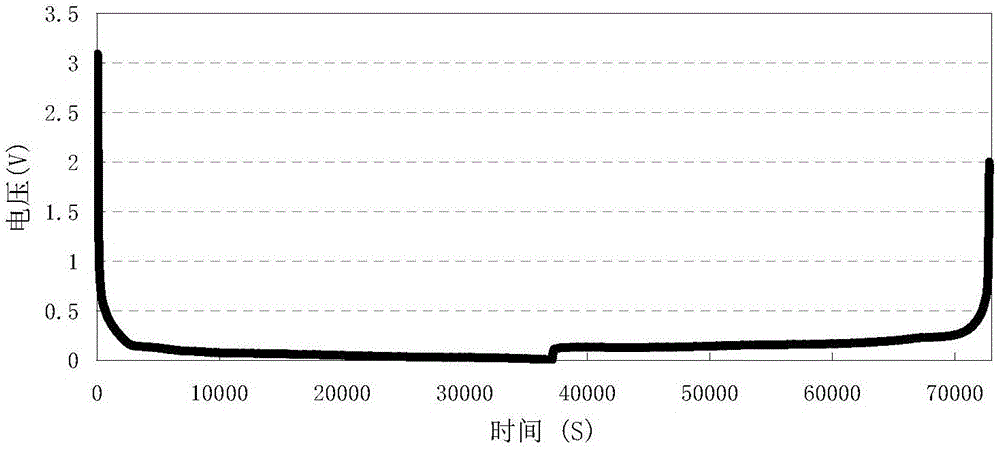

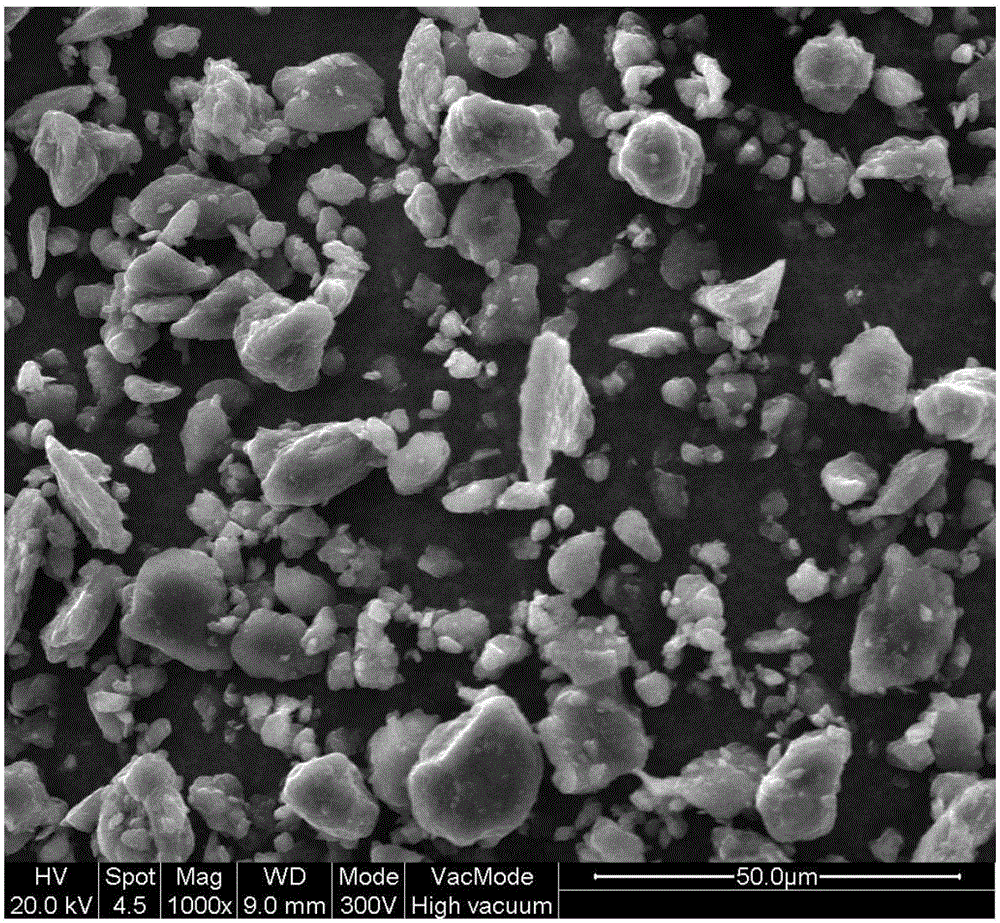

[0038] Under stirring, alternately add microcrystalline graphite powder and petroleum pitch powder into the mixing pot and mix. Under the protection of nitrogen, heat treatment at a low temperature of 500 ° C for 16 hours, then cool the reaction product to room temperature, and then conduct high-temperature treatment of graphitization at 2900 ° C for 48 hours, mix and sieve, and obtain particles with a particle size D50 of 10.3μm low-expansion long-cycle natural graphite, its half-cell capacity is 368.1mAh / g, and the first-time efficiency is 96.2%, see figure 1 and figure 2 .

Embodiment 3

[0040] Microcrystalline graphite powder: D50 is 5.1μm, 200kg;

[0041] Graphitizable binder: coal tar pitch powder below 5μm, 40kg;

[0042] Under stirring, alternately add microcrystalline graphite powder and coal tar pitch powder to the mixing pot and mix. Under the protection of nitrogen, heat treatment at a low temperature of 800 ° C for 10 hours, then cool the reaction product to room temperature, and then conduct high-temperature treatment of graphitization at 3000 ° C for 48 hours, mix and sieve, and obtain particles with a particle size D50 of 7.4μm low-expansion long-cycle natural graphite, its half-cell capacity is 370.0mAh / g, and the first-time efficiency is 95.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com