Halogen-free and flame-retardant long glass fiber reinforced TPEE composite material and preparation method thereof

A composite material, long glass fiber technology, applied in the field of material science, can solve the problems of increased melt viscosity, inability to complete glass fiber impregnation, short glass fiber reinforced TPEE material performance can not meet the requirements and other problems, to achieve excellent flame retardant effect, preparation The effect of reducing energy consumption and excellent mechanical properties of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

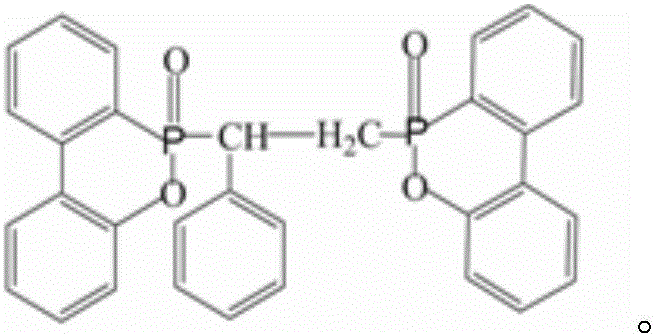

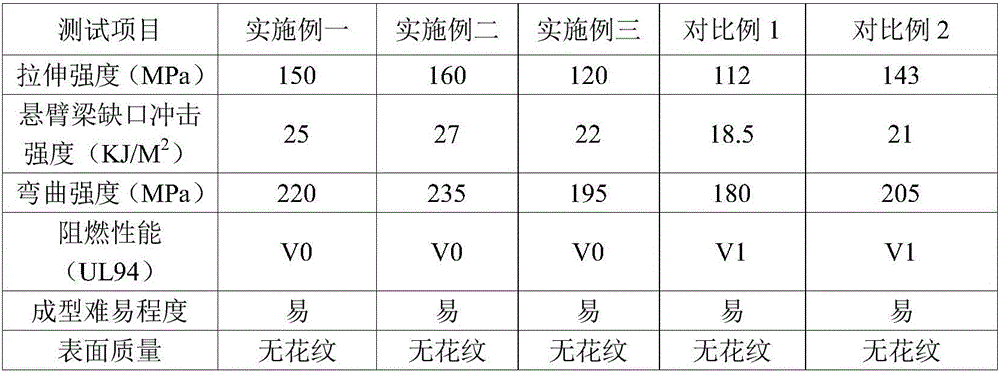

[0012] Embodiment 1 of the present invention: Halogen-free flame-retardant long glass fiber reinforced TPEE composite material, calculated in parts by weight, including 45 parts of thermoplastic polyester elastomer, 30 parts of glass fiber, 10 parts of DIDOPO, 0.5 part of antioxidant, 4 1 part of compatibilizer, 4 parts of triazine char-forming agent and 1 part of synergist are raw materials for preparation; the antioxidant is high-efficiency antioxidant 245; the compatibilizer is SAG-008; the synergist The effect agent is quaternary phosphorus salt intercalation modified montmorillonite.

[0013] The preparation method of halogen-free flame-retardant long glass fiber reinforced TPEE composite material, the specific preparation scheme is to take thermoplastic polyester elastomer, DIDOPO, triazine char-forming agent and synergist to dry for standby; take the dried thermoplastic polyester elastomer , DIDOPO, triazine char-forming agent and synergist, antioxidant and compatibiliz...

Embodiment 2

[0014] Example 2: Halogen-free flame-retardant long glass fiber reinforced TPEE composite material, calculated in parts by weight, including 30 parts of thermoplastic polyester elastomer, 40 parts of glass fiber, 11.5 parts of DIDOPO, 0.5 part of antioxidant, 3 parts of compatible agent, 5 parts of triazine char-forming agent and 1 part of synergist are the raw materials for preparation; the antioxidant is antioxidant 1010; the compatibilizer is SAG-008; the synergist is quaternary Phosphate intercalation modified montmorillonite.

[0015] The preparation method is the same as implementation 1.

Embodiment 3

[0016] Example 3: Halogen-free flame-retardant long glass fiber reinforced TPEE composite material, calculated in parts by weight, including 60 parts of thermoplastic polyester elastomer, 20 parts of glass fiber, 9 parts of DIDOPO, 0.5 part of antioxidant, 5 parts of compatible agent, 3 parts of triazine char-forming agent and 1 part of synergist are the raw materials for preparation; the antioxidant is high-efficiency antioxidant 245; the compatibilizer is SAG-008; the synergist is Quaternary phosphorus salt intercalation modified montmorillonite.

[0017] The preparation method is the same as implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com