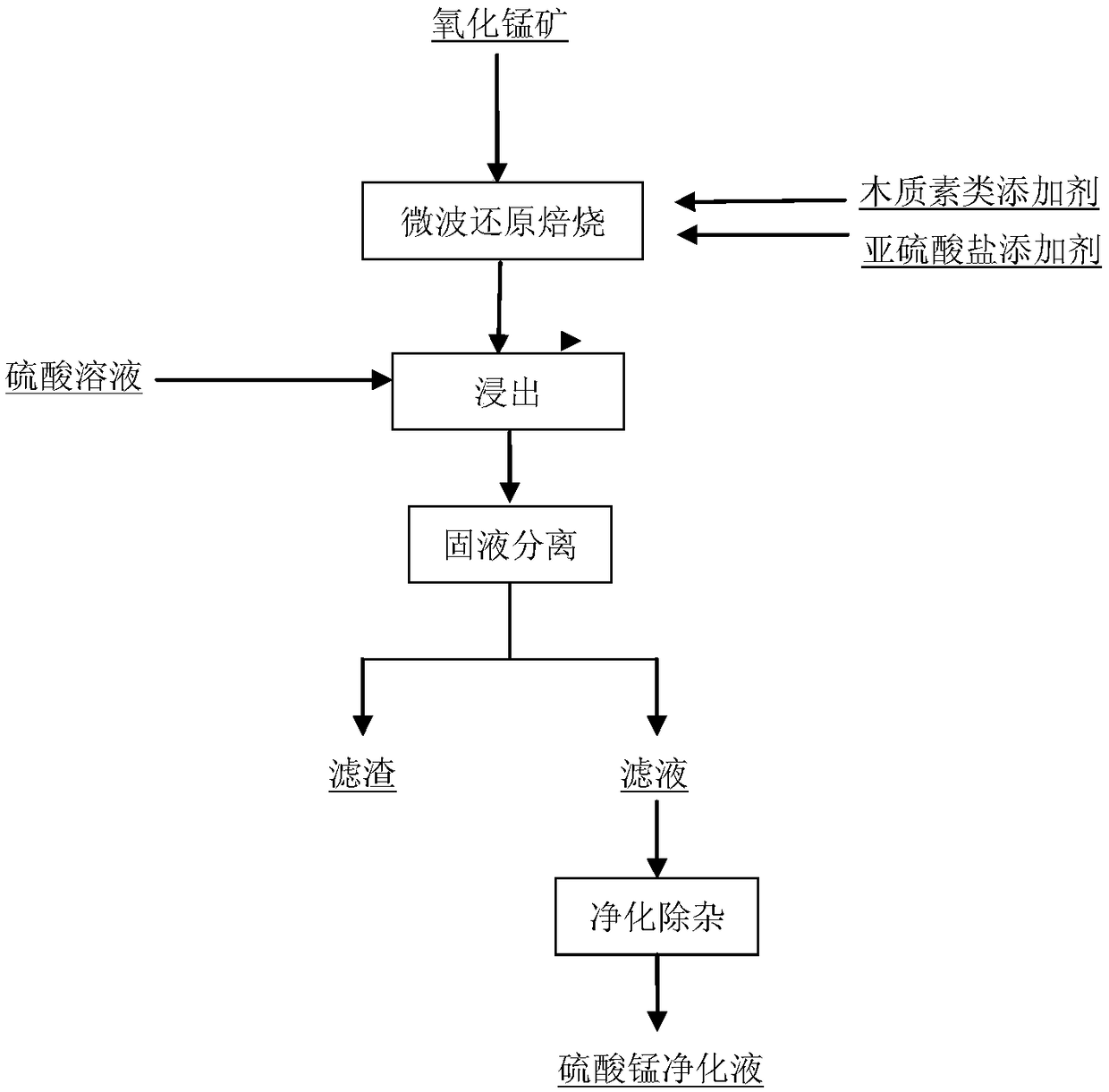

A kind of microwave reduction roasting and extraction method of manganese oxide ore

A technology of manganese oxide ore and extraction method, applied in the field of metallurgy, can solve the problems of high reduction temperature, complex composition, great influence of conditions, etc., and achieve the effects of mild leaching conditions, lower production costs, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The ore samples are taken from low-grade manganese oxide ore samples in Xiangxi, Hunan. The main manganese mineral is pyrolusite, with a manganese grade of 20.34%, an iron grade of 10.46%, a silicon dioxide of 37.22%, and aluminum oxide of 8.38%. The ore is crushed to a particle size below 74 μm. Alkali lignin was purchased from Shandong Weili Chemical Technology Co., Ltd., an industrial product with a molecular weight of 1,000 to 100,000. Its main technical indicators are: moisture≤7.0%, pH value (1% aqueous solution) 11~12, reduced content≤4.0%, Fineness (120 mesh sieve residue) ≤ 2.0%, calcium and magnesium content ≤ 0.5%.

[0031] Mix evenly according to the mass ratio of manganese oxide ore sample: alkali lignin: sodium sulfite = 100:15:5, place in a microwave reaction device for heating and roasting, control the roasting temperature at 150°C, and roast for 5 minutes. After the reaction is completed, roast the sand in the furnace Cool naturally, crush the calcined...

Embodiment 2

[0033] The ore samples are taken from manganese oxide ore in Guangxi, the main manganese mineral is pyrolusite, the grade of manganese is 27.78%, the grade of iron is 4.20%, the grade of silicon dioxide is 27.11%, and the grade of aluminum oxide is 8.53%. The ore is crushed to a particle size below 0.25mm. Alkali lignin is the same as in Example 1.

[0034] The amount of alkali lignin is 20% of manganese oxide ore, and the amount of sodium sulfite is 7.5% of manganese oxide ore. Mix them evenly and place them in a microwave reaction device, adjust the roasting temperature to 200°C, and roast for 10 minutes. Below 0.25mm, sulfuric acid concentration 1.5mol / L, liquid-solid ratio 4:1, stirring and leaching at 50°C for 10 minutes, the manganese leaching rate was 95.28%, and the TOC value (total organic carbon content) of the leachate was 25.3437mg / L. After solid-liquid separation, the filtrate can be purified by conventional purification and impurity removal methods to obtain qua...

Embodiment 3

[0036] The ore samples were taken from manganese oxide ore in Gabon, the main manganese mineral is pyrolusite, the grade of manganese is 45.62%, the grade of iron is 2.75%, the grade of silicon dioxide is 10.78%, and the grade of aluminum oxide is 9.65%. The ore is ground to a particle size of 0.25mm or less. Alkali lignin is the same as in Example 1.

[0037] Prepare the mixture of additives and ore samples, control the alkali lignin to be 30% of the manganese oxide ore, and the amount of sodium sulfite to be 7.5% of the manganese oxide ore. After cooling, crush the calcined sand to less than 0.25mm, add sulfuric acid solution with a concentration of 1.5mol / L and stir for leaching, control the leaching conditions as liquid-solid ratio 10:1, leaching temperature 50°C, leaching time 10min, solid-liquid separation leaching slag and leachate, the manganese leaching rate was 95.67%, and the TOC value (total organic carbon content) of the leachate was 31.2143mg / L. The concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com