A kind of method for preparing ammonium molybdate by molybdenite

A technology of molybdenite and ammonium molybdate, which is applied in the field of molybdenum smelting, can solve the problems of refractory acid-containing wastewater, increased treatment costs, serious equipment corrosion, etc., achieve low equipment requirements, reduce waste residue and wastewater discharge, and reduce environmental pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

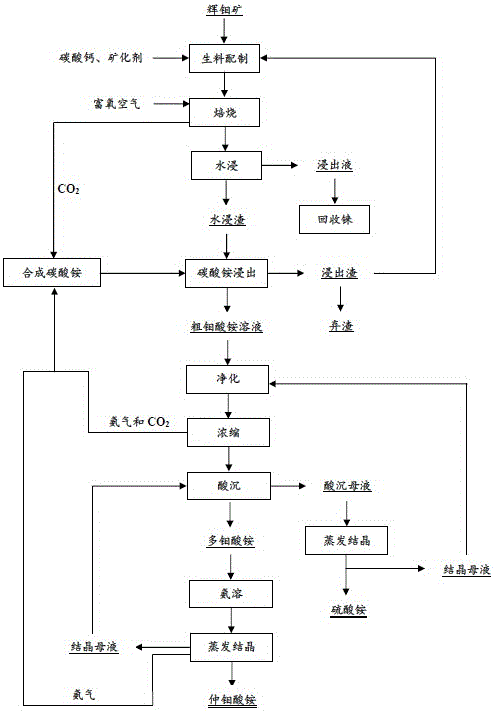

Image

Examples

Embodiment 1

[0039] Example 1: Press CaCO 3 / MoS 2 The molar ratio is 3.6. Calcium carbonate, a certain molybdenite (the mass percentage of Mo is 40.33%) and 3% calcium fluoride are ground and mixed to obtain a raw meal. The raw meal size D90 is 110 μm. Then, the raw meal is roasted in an oxygen-rich atmosphere at 600° C. for 2 hours in a roasting furnace to obtain clinker. After the clinker is cooled to room temperature, it is finely ground with a vibration mill, and the clinker particle size D90 is 130 μm. After the clinker is leached with water, solid-liquid separation is performed, and rhenium is recovered from the leachate. The leaching residue after water leaching is added to a stirred leaching tank, leached with an ammonium carbonate solution with a concentration of 800g / L, and reacted at 100°C for 4 hours. After the reaction, the leaching pulp is vacuum filtered, and the filter cake is washed three times with pure water. The molybdenum leaching rate in molybdenite is 98.12%. Afte...

Embodiment 2

[0040] Example 2: Press CaCO 3 / MoS 2 The molar ratio is 3.0. Calcium carbonate, a certain molybdenite (the mass percentage of Mo is 40.33%) and 2% calcium fluoride are ground and mixed to obtain a raw meal. The raw meal size D90 is 100μm. Then, the raw meal is roasted in an oxygen-rich atmosphere at 600°C for 0.5 hour in a roasting furnace to obtain clinker. After the clinker is cooled to room temperature, it is ground with a vibration mill, and the clinker particle size D90 is 70 μm. After the clinker is leached with water, solid-liquid separation is performed, and rhenium is recovered from the leachate. Add the leaching residue after water leaching into a stirred leaching tank, leaching with an ammonium carbonate solution with a concentration of 300g / L, and reacting at 90°C for 6 hours. After the reaction, the leaching pulp is vacuum filtered, and the filter cake is washed three times with pure water. The molybdenum leaching rate in molybdenite is 75.61%. Then, similar to...

Embodiment 3

[0041] Example 3: Press CaCO 3 / MoS 2 The molar ratio is 5.0. Calcium carbonate, a certain molybdenite (the mass percentage of Mo is 40.33%) and 10% calcium fluoride are ground and mixed to obtain a raw meal. The raw meal size D90 is 80 μm. Then, the raw meal was baked in a roasting furnace with air and roasted at 400°C for 6 hours to obtain clinker. After the clinker is cooled to room temperature, it is ground with a vibration mill, and the clinker particle size D90 is 70 μm. After the clinker is leached with water, solid-liquid separation is performed, and rhenium is recovered from the leachate. The leaching residue after water leaching is added to the leaching equipment, the leaching equipment is a leaching tank with stirring, leached with an ammonium carbonate solution with a concentration of 800g / L, and reacted at 70°C for 8 hours. After the reaction, the leaching pulp is vacuum filtered, and the filter cake is washed three times with pure water. The molybdenum leaching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com