A kind of cold yarn and its preparation method and application

A yarn and ice-cooling technology, which is applied in the field of ice-cooled yarn and its preparation, can solve the problems of poor anti-ultraviolet effect, washing three to five times, and loss of effect, etc., and achieve excellent moisture absorption, heat absorption, heat dissipation, excellent cooling and ventilation, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

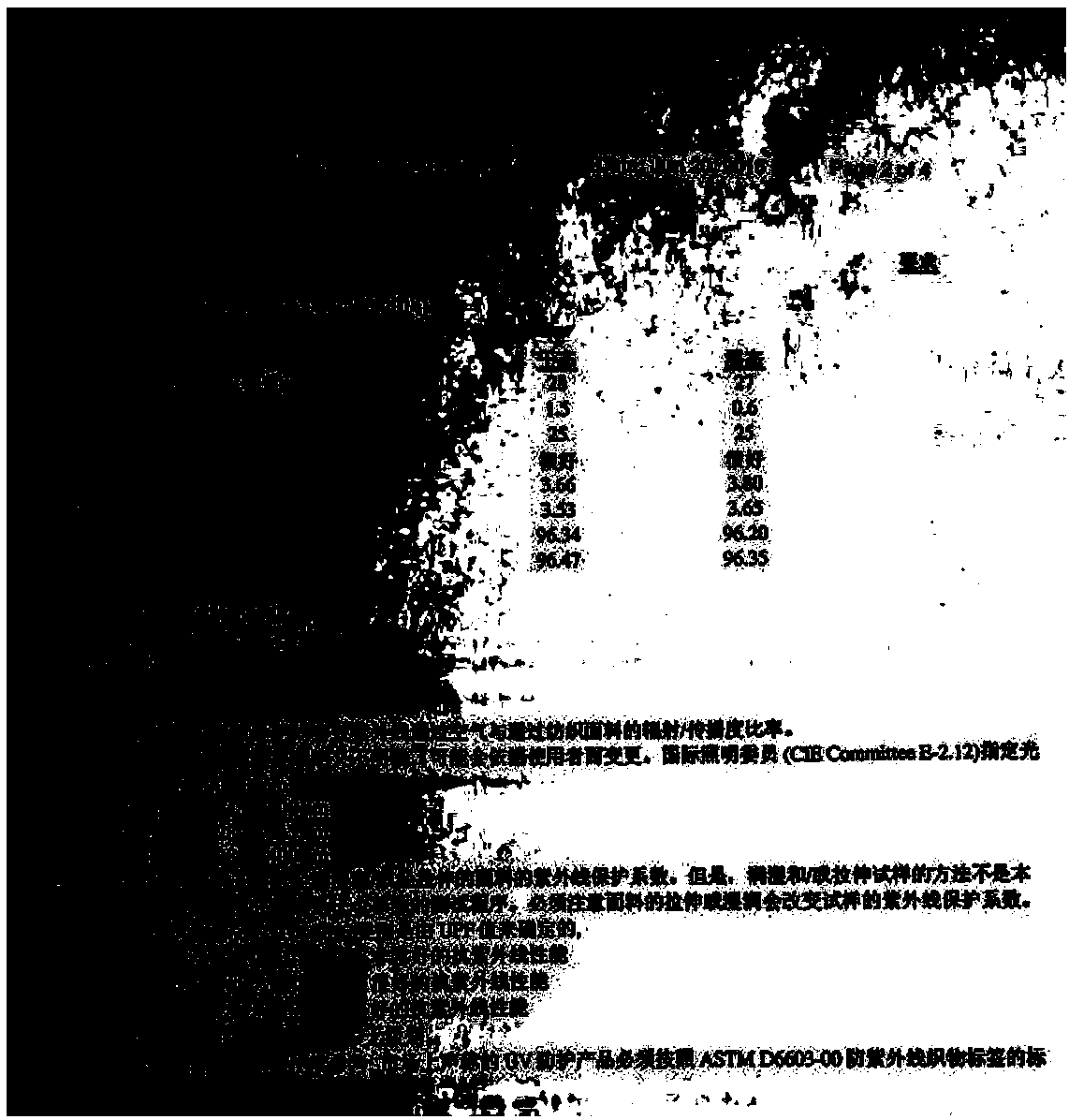

Image

Examples

Embodiment 1

[0054] (1) the jade ore (average hardness 5 degrees) of the raw material component 7.5 mass parts of ice-cold yarn, the crystal stone (average hardness 5 degrees) of 3 mass parts, the silver ore (average hardness 5 degrees) of 3 mass parts and 1.5 mass parts of copper ore (average hardness 5 degrees) are ground respectively through diamond emery wheel, and then grind with nano-grinding machine, obtain nanoscale jade ore, crystal stone, silver ore and copper ore powder (particle size is 50 ~100nm), and then mixed to obtain ore masterbatch;

[0055] (2) the polyamide fiber of 80 mass parts is dissolved in ethylene dichloride, obtains the spinning solution that mass fraction is 45%, then adds the anti-ultraviolet agent nano-titanium dioxide (particle diameter is 100nm) of 5 mass parts and 15 mass fractions The ore master batches prepared in step (1) are mixed evenly, and are spun by dry spinning method, wherein, the spinning speed is 200m / min to obtain ore master batches-anti-ultra...

Embodiment 2

[0060] (1) the jade ore (average hardness 2 degrees) of the raw material component 6 mass parts of ice-cold yarn, the crystal stone (average hardness 2 degrees) of 2.4 mass parts, the silver ore (average hardness 2 degrees) of 2.4 mass parts and The copper ore (average hardness 2 degrees) of 1.2 mass parts is through diamond emery wheel grinding respectively, then grinds with nano-grinding machine, obtains the jade ore of nanoscale, crystal stone, silver ore and copper ore powder (particle size is 20 ~50nm), and then mixed to obtain ore masterbatch;

[0061] (2) 85 mass parts of polyamide fibers are dissolved in ethylene dichloride to obtain a spinning solution with a mass fraction of 25%, and then add 3 mass parts of anti-ultraviolet agents (nano titanium dioxide (particle size is 200nm) and nano Zinc oxide (particle size 100nm) mass ratio 1:1) and 12 parts by mass of the ore masterbatch prepared in step (1) are mixed evenly, and the dry spinning method is used for spinning, ...

Embodiment 3

[0066] (1) the jade ore (average hardness 4 degrees) of the raw material component 5 mass parts of ice-cold yarn, the crystal stone (average hardness 4 degrees) of 2 mass parts, the silver ore (average hardness 4 degrees) of 2 mass parts and After the copper ore (average hardness 4 degrees) of 1 mass part is ground respectively through diamond emery wheel, then grind with nano-grinding machine, obtain the jade ore of nanoscale, crystal stone, silver ore and copper ore powder (particle size is 50 ~80nm), and then mixed to obtain ore masterbatch;

[0067] (2) 83 mass parts of polyamide fibers are dissolved in ethylene dichloride to obtain a spinning solution with a mass fraction of 15%, and then add 4 mass parts of an anti-ultraviolet agent (nano-titanium dioxide (particle diameter is 50nm) and ultraviolet light Absorber UV328 (mass ratio 1:1) and 10 parts by mass of the ore masterbatch prepared in step (1) are mixed evenly, and the dry spinning method is used for spinning, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com