Green edible grade softening agent for textile printing and dyeing and preparing method thereof

A textile printing and dyeing, food-grade technology, applied in the field of textile printing and dyeing, can solve the problems of poor biodegradability, redness, and unenvironmental protection, and achieve the effect of good biodegradability and good softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

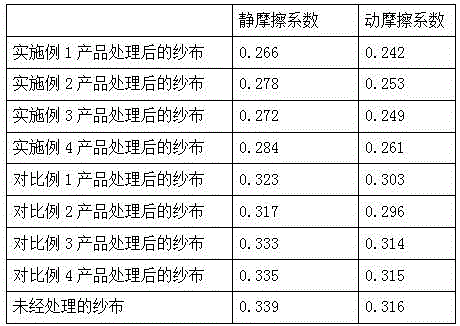

Examples

Embodiment 1

[0019] Prepare raw materials: 35kg of lard, 50kg of stearic acid, 38kg of liquid caustic soda, 260kg of distilled water, 6kg of ethanol, 6kg of isopropanol and 16kg of polyoxyethylene sorbitan fatty acid ester T-60; mix liquid caustic soda, distilled water and ethanol for mixed liquids;

[0020] Preparation process: heat lard and stearic acid to 80°C in a reaction kettle, stir until melted; add the mixed liquid dropwise into the reaction kettle, and the time used for the dropwise addition is 36 minutes; then raise the temperature of the reaction kettle to 86°C, After keeping warm for 1.6 hours, add isopropanol dropwise (the time used for dropping is 6 minutes), keep warm for 28 minutes, then add polyoxyethylene sorbitan fatty acid ester T-60, and stir for 10 minutes.

Embodiment 2

[0022] Prepare raw materials: lard 45kg, stearic acid 60kg, liquid caustic soda 45kg, distilled water 150kg, ethanol 4kg, isopropanol 8kg, and polyoxyethylene sorbitan fatty acid ester T-60 26kg; liquid caustic soda, distilled water and ethanol mixed into a mixed liquid;

[0023] Preparation process: with embodiment 1.

Embodiment 3

[0025] Prepare raw materials: lard 35kg, stearic acid 50kg, liquid caustic soda 38kg, distilled water 150kg, ethanol 4kg, isopropanol 8kg, and polyoxyethylene sorbitan fatty acid ester T-60 26kg; liquid caustic soda, distilled water and ethanol mixed into a mixed liquid;

[0026] Preparation process: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com