Method for co-production of high-concentration liquid CO2 by utilizing low-temperature methanol washing process

A low-temperature methanol washing and high-concentration technology, applied in chemical instruments and methods, liquefaction, products, etc., can solve the problem of high energy consumption and achieve the effects of enhanced energy conservation and environmental protection, large-scale products, and reduced energy consumption and material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

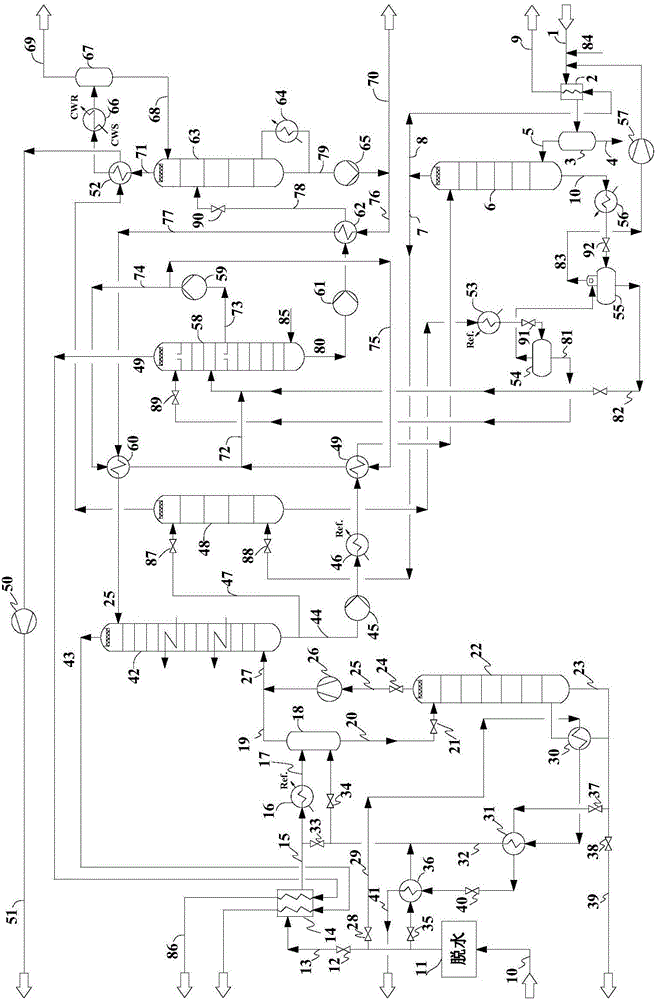

[0039] Such as figure 1 As shown, the low-temperature methanol washing process is used to purify two different feed gases, which are the sulfur-containing shift gas 1 from the upstream shift unit and the CO-enriched gas from the methanation unit.2 1. The sulfur-free crude methane feed gas 10 is used to co-produce part of the high-concentration liquid carbon dioxide product through the present invention during the desulfurization and decarbonization process using the low-temperature methanol washing process.

[0040] In this embodiment, the temperature of raw material gas 10 is 40°C, the pressure is 5.5MPa(G), and the flow rate is 180kNm 3 / h, the concentration of each component in the feed gas 10 is CO 2 : 66.7%, CH 4 : 32.7%, H 2 : 0.16%, N 2 : 0.24%, Ar: 0.2%, the present invention is realized through the following steps:

[0041] (1). After the raw material gas 10 is dried by the dehydration system 11, the water content in the raw material gas 10 is less than 20ppm;

...

Embodiment 2

[0060] Such as figure 1 As shown, the low-temperature methanol washing process is used to purify two different feed gases, which are the sulfur-containing shift gas 1 from the upstream shift unit and the CO-enriched gas from the methanation unit. 2 1. Sulfur-free crude methane gas 10 is used to co-produce part of high-concentration liquid carbon dioxide products through the present invention during the desulfurization and decarbonization process using the low-temperature methanol washing process.

[0061] In this embodiment, the temperature of raw material gas 10 is 40°C, the pressure is 3.1MPa(G), and the flow rate is 162kNm 3 / h, the concentration of each component in the feed gas 10 is CO 2 : 68%, CH 4 : 31.33%, H 2 : 0.18%, N 2 : 0.35%, Ar: 0.14%, the present invention is realized through the following steps:

[0062] (1). After the raw material gas 10 is dried by the dehydration system 11, the water content in the raw material gas 10 is less than 20ppm;

[0063] (2)...

Embodiment 3

[0070] Such as figure 1 As shown, the low-temperature methanol washing process is used to purify two different feed gases, which are the sulfur-containing shift gas 1 from the upstream shift unit and the CO2-rich, sulfur-free crude methane gas from the methanation unit 10. Through the method and device of the present invention, the output of liquid carbon dioxide products can be flexibly adjusted.

[0071] In this embodiment, the temperature of raw material gas 10 is 40°C, the pressure is 5.5MPa(G), and the flow rate is 180kNm 3 / h, the concentration of each component in the feed gas 10 is CO 2 : 66.7%, CH 4 : 32.7%, H 2 : 0.16%, N 2 : 0.24%, Ar: 0.2%, the present invention realizes the joint production of liquid carbon dioxide product through the following steps:

[0072] (1). After the raw material gas 10 is dried by the dehydration system 11, the water content in the raw material gas 10 is less than 20ppm;

[0073] (2). Part of the raw material gas-13 dehydrated in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com