Perovskite laminated solar cell and preparation method thereof

A technology of perovskite cells and tandem solar, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex preparation process of HIT-type tandem cells, narrow photon energy absorption range, difficult industrial production, etc. The effect of improved conversion efficiency, enhanced optoelectronic properties, and enhanced photon absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

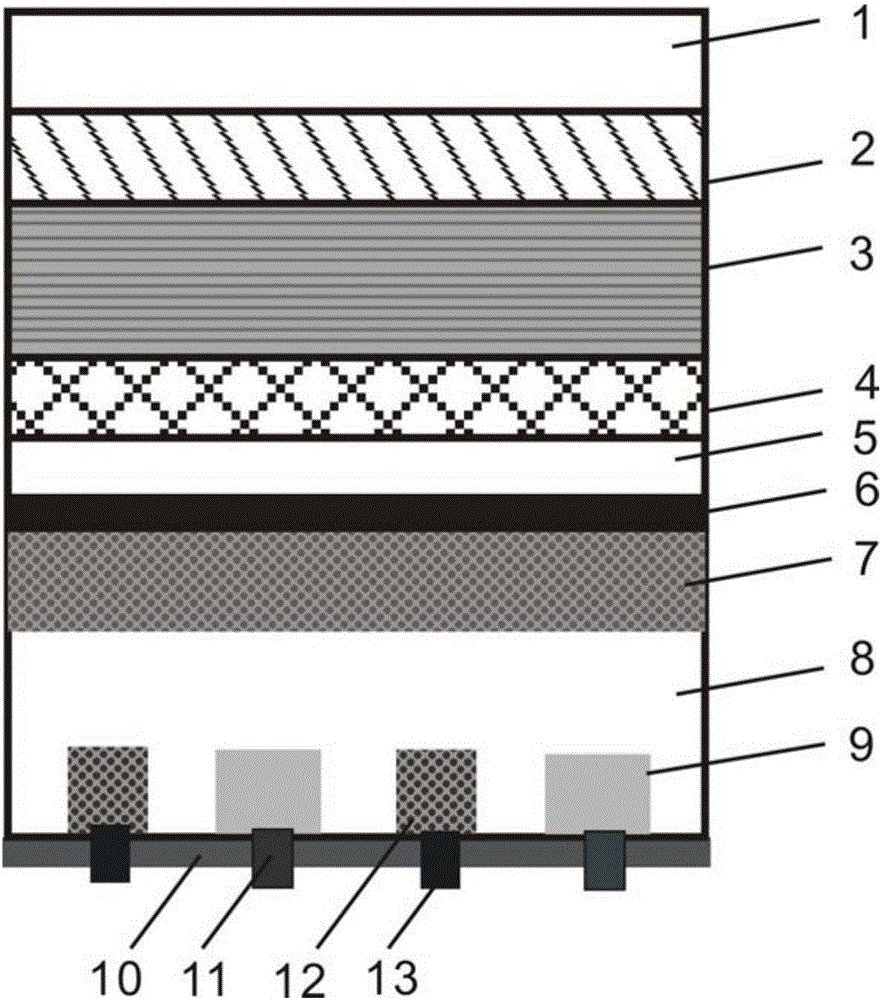

[0037] like figure 1 , the present embodiment provides a method for manufacturing a perovskite solar cell with multiple light-absorbing layers, the cell comprising: conductive glass 5, an electron transport layer 4, a perovskite multiple light-absorbing layer 3, a hole transport layer 2, Top conductive layer 1, anti-reflection passivation layer 6, phosphorus diffusion front field 7, silicon substrate 8, back surface passivation layer 10, p + Diffusion area 9, n ++ heavily doped region 12, p + Diffusion area electrodes 11, n ++ Heavily doped regional electrodes 13 . The perovskite multiple light-absorbing layer structure in this example contains three perovskite monolayers, and each layer contains a single perovskite molecular component. From bottom to top, they are perovskite I layer, perovskite II layer, Perovskite III layer. These three perovskite molecules have partly the same composition, layer I is AMX 3 Perovskite layer, layer II is AMX 2 Y 1 , Tier III for AMX ...

Embodiment 2

[0055] This embodiment provides a method for manufacturing a perovskite solar cell with multiple light-absorbing layers, the battery comprising: conductive glass 5, electron transport layer 4, perovskite multiple light-absorbing layer 3, hole transport layer 2, top Conductive layer 1, anti-reflection passivation layer 6, phosphorus diffusion front field 7, silicon substrate 8, back surface passivation layer 10, p + Diffusion area 9, n ++ heavily doped region 12, p + Diffusion area electrodes 11, n ++ Heavily doped regional electrodes 13 . The perovskite multiple light-absorbing layer structure in this example contains a perovskite monolayer, and its composition is (C 6 h 5 C 2 h 4 NH 3 ) 2 PB 4 Its absorption bandwidth is 2.3eV, and its layer thickness is 500nm.

[0056] 1) Select an n-type silicon substrate with a resistivity of 2-5Ω·cm, and remove the damaged layer.

[0057] 2) Carry out double-sided texturing on the silicon wafer with potassium hydroxide NaOH alk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com