High-moisture sludge pyrolysis method and device

A pyrolysis and sludge technology, which is applied in the pyrolysis treatment of sludge, gasification process, petroleum industry, etc., can solve the problems of small heating and heat transfer area, large energy consumption, low utilization rate, etc. Increase the response time, the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

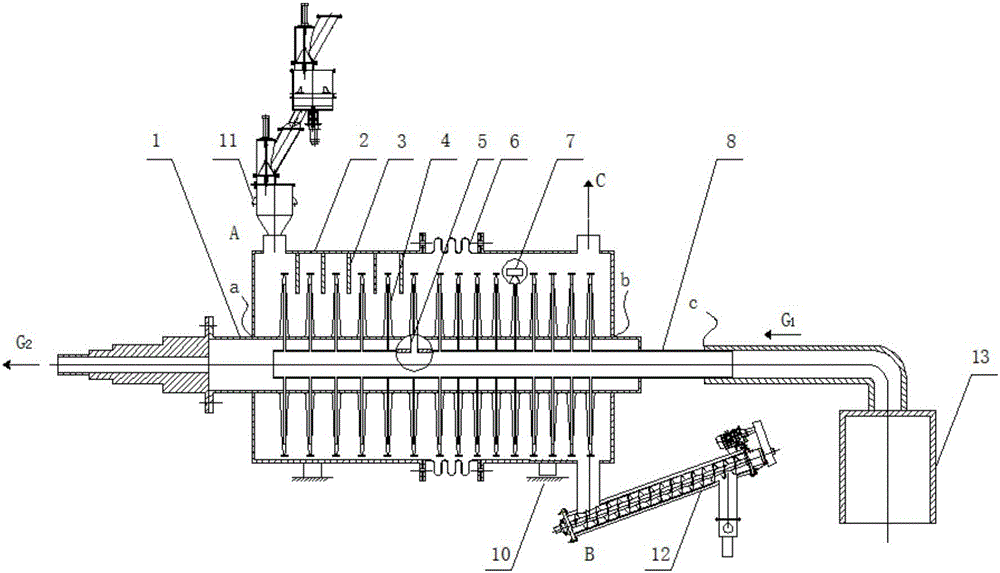

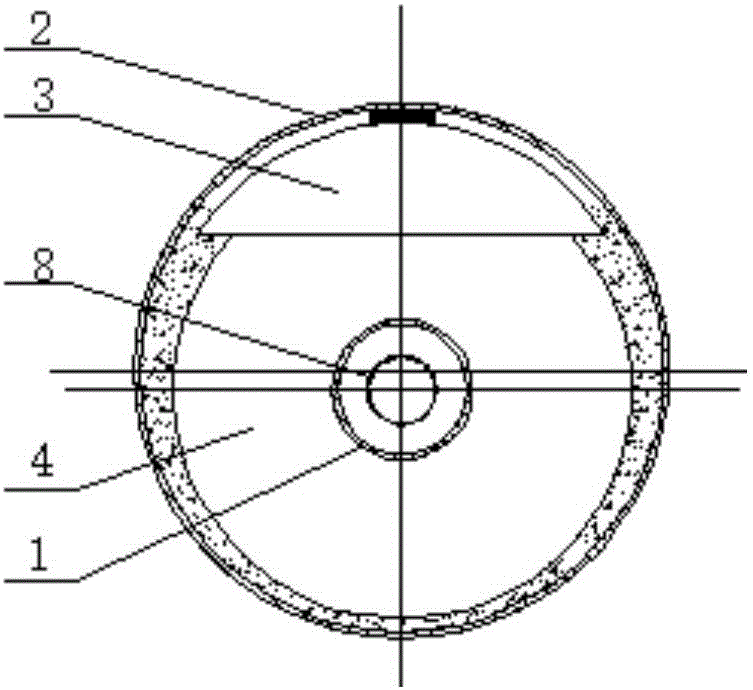

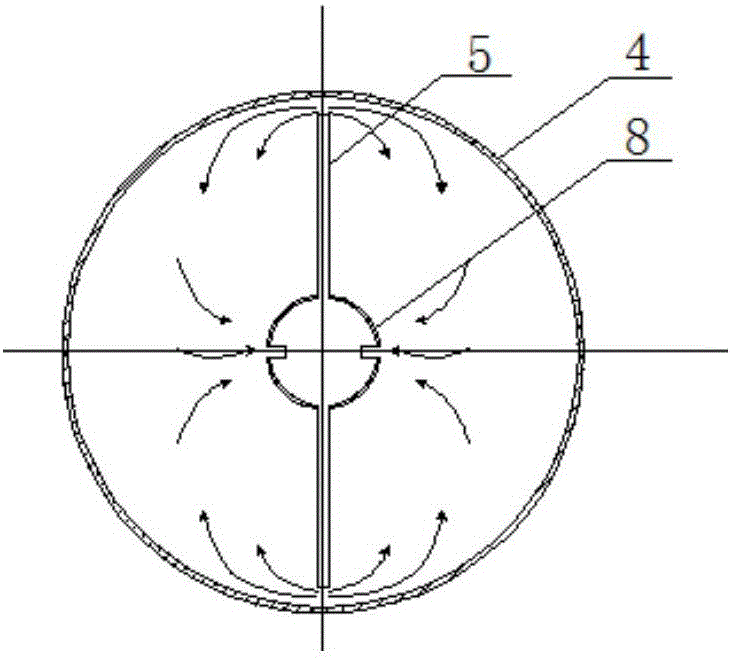

[0036] combine Figure 1~5 The present invention is further described.

[0037] A pyrolysis device for high-humidity sludge, consisting of a hollow shaft 1, a casing 2, a scraper 3, a set of hollow discs 4, a heat medium drainage pipe 5, an expansion joint 6, a propeller 7, and a heat medium delivery pipe 8 , agitator 9, sliding support 10, sealed feed system 11, sealed discharge system 12, biomass powder burner 13, material inlet A, material outlet B and gas outlet C; wherein the hollow shaft 1 is close to the biomass powder combustion One end of device 13 is connected to heat medium inlet G 1 , the other end is connected to heat medium outlet G 2 , where shell 2 is close to heat medium outlet G 2 There is a material inlet A on the upper part of one end, which is connected to the sealed feeding system 11, and the shell 2 is close to the heat medium inlet G 1 There is a gas outlet C on the upper part of one end, and a material outlet B on the lower part, which is connected...

Embodiment 2

[0040] The main parameters of the high-humidity sludge pyrolysis device provided in this embodiment are as follows: the number of disks is 40, and the diameter of the disks is 120 cm; the distance between the two disks near the material inlet end is 17 cm, and the distance between the two disks near the material outlet end The distance between the two disks is 13cm; 6 agitators are arranged on the wall of each disk; the number of scrapers is 15, the height is 40cm, and the thickness is 5cm.

[0041] High-humidity sludge with a moisture content of 79.51% and biomass with a moisture content of 12.87% were used as pyrolysis raw materials in a ratio of 6:4. Among them, the sludge is taken from the dewatered sludge of a domestic sewage treatment plant in Nanjing, and the biomass micropowder comes from a wood processing plant in Wuhan. After the mixture is stirred evenly, the material inlet A continuously enters the disk device through the sealed feeding system. At this time, the hi...

Embodiment 3

[0047] The main parameters of the high-humidity sludge pyrolysis device provided in this embodiment are as follows: the number of disks is 20, and the diameter of the disks is 60 cm; the distance between the two disks near the material inlet end is 15 cm, and the distance between the two disks near the material outlet end The distance between the two disks is 10cm; 4 agitators are arranged on the wall of each disk; the number of scrapers is 5, the height is 15cm, and the thickness is 3cm.

[0048] Mixed material parameters are the same as in Example 2. After the mixture is stirred evenly, the material feed A continuously enters the disc device through the sealed feed system. At this time, the high-temperature flue gas enters G 1 The temperature at the place is about 1000℃, the flue gas flow rate is 8m / s, and the flue gas outlet G 2 The temperature at the place is about 150°C, and the flow velocity is 2m / s. The material entering the device is heated by the disc, shell and hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com