Fenugreek gum containing sulfo carboxymethyl and preparation method and application of fenugreek gum

A technology containing sulfonic acid carboxymethyl group and sulfonic acid carboxymethyl group, which is applied in the field of modified products of natural plant polysaccharides, can solve the problem of no improvement in the salt resistance and temperature resistance of fenugreek gum, and the chemical modification of fenugreek gum. low solubility, shorten the dissolution time, etc., to achieve the effect of low water insoluble content, fast dissolution speed and good salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the sulfonic acid group-containing carboxymethyl fenugreek gum includes the following steps:

[0046] (1) Add 100g of carboxymethyl fenugreek gum to 1L of alcohol aqueous solution;

[0047] (2) Blow in nitrogen, add aqueous sodium hydroxide solution (with sodium hydroxide content of 1g-3g) dropwise while stirring for 0.5h; then stir and heat up to 60-80°C, add 0.03g-0.6g sulfuric acid dropwise Chemical agent, the dropping time is 1h, and the reaction is 2-4 hours after the dropping, preferably 3 hours;

[0048] (3) Acid adjust the reaction solution to neutrality, filter, and vacuum dry to obtain light yellow powder, which is sulfonic acid group-containing carboxymethyl fenugreek gum.

[0049] In step (1):

[0050] The aqueous alcohol solution is an aqueous ethanol solution with a mass fraction of 50%-80%, preferably 50%;

[0051] The mass fraction of the sodium hydroxide aqueous solution is 5%-30%, preferably 10%.

[0052] In step (2), the sulfonating age...

Embodiment 1

[0087] The preparation method of sulfonic acid modified carboxymethyl fenugreek gum, the steps are as follows:

[0088] (1) Add 100.0g of carboxymethyl fenugreek gum to a 1L 50% ethanol solution reactor;

[0089] (2) Under nitrogen environment, add 10.0g 10% sodium hydroxide aqueous solution dropwise, add dropwise for 0.5h, then raise the temperature to 70℃, stir for 0.5 hour, add dropwise 3.0g 10% sodium 3-chloro-2-hydroxypropanesulfonate solution, Constant temperature 60℃, 1h dripping is completed, continue to stir for 2 hours;

[0090] (3) The reaction liquid is neutralized to neutrality, filtered, and dried in vacuum to obtain the light yellow powder product SCFG-1.

[0091] Product performance test results:

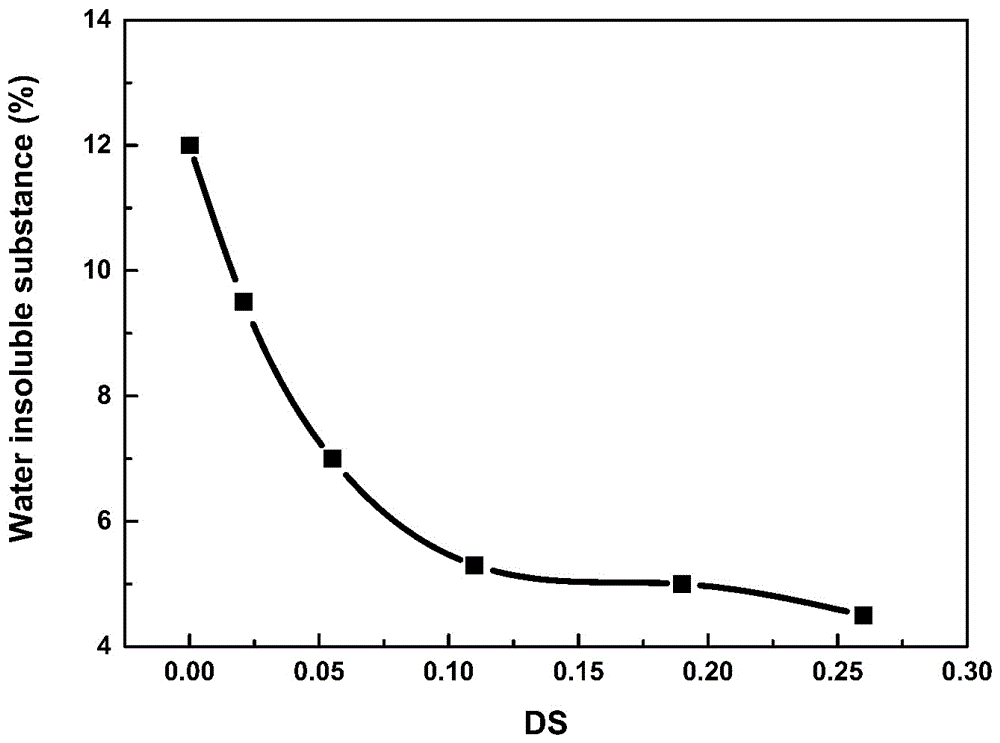

[0092] The degree of substitution (DS) of the product SCFG-1 is 0.020.

[0093] The water-insoluble content of the product SCFG-1 is 8.3%.

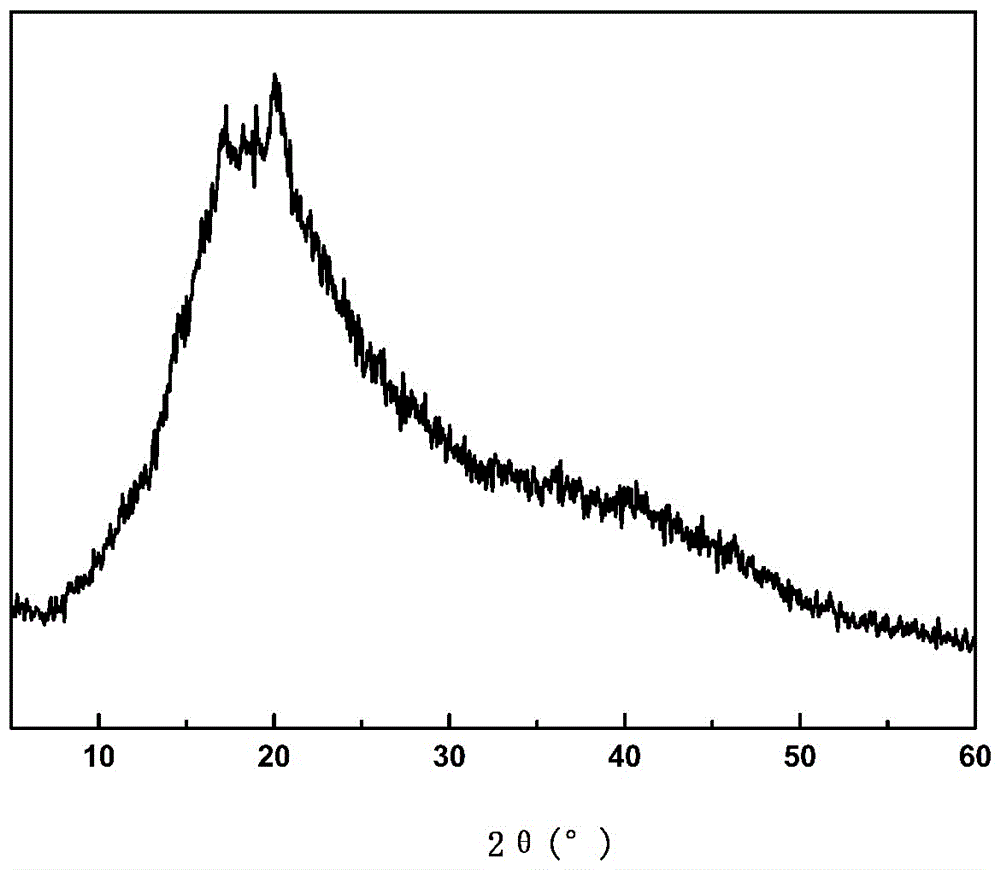

[0094] The crystallinity of the product SCFG-1 decreases, and the introduction of sulfonic acid groups will reduce the order of molecular...

Embodiment 2

[0099] The preparation method of sulfonic acid modified carboxymethyl fenugreek gum, the steps are as follows:

[0100] (1) Add 100.0g of carboxymethyl fenugreek gum to a 1L 50% ethanol solution reactor;

[0101] (2) In a nitrogen environment, add 15.0g of 10% sodium hydroxide aqueous solution dropwise, add dropwise for 0.5h, then raise the temperature to 85℃, stir for 0.5 hour, dropwise add 30g of 10% sodium 3-chloro-2-hydroxypropanesulfonate solution, After 1h dripping is completed, continue to stir for 2 hours;

[0102] (3) The reaction liquid is neutralized to neutrality, filtered, and dried in vacuum to obtain the light yellow powder product SCFG-2.

[0103] Product performance test results:

[0104] The degree of substitution (DS) of the product SCFG-2 is 0.22.

[0105] The water-insoluble content of the product SCFG-2 is 4.8%; compared with Example 1, the water-insoluble content is reduced.

[0106] The crystallinity of the product SCFG-2 is 1.30%.

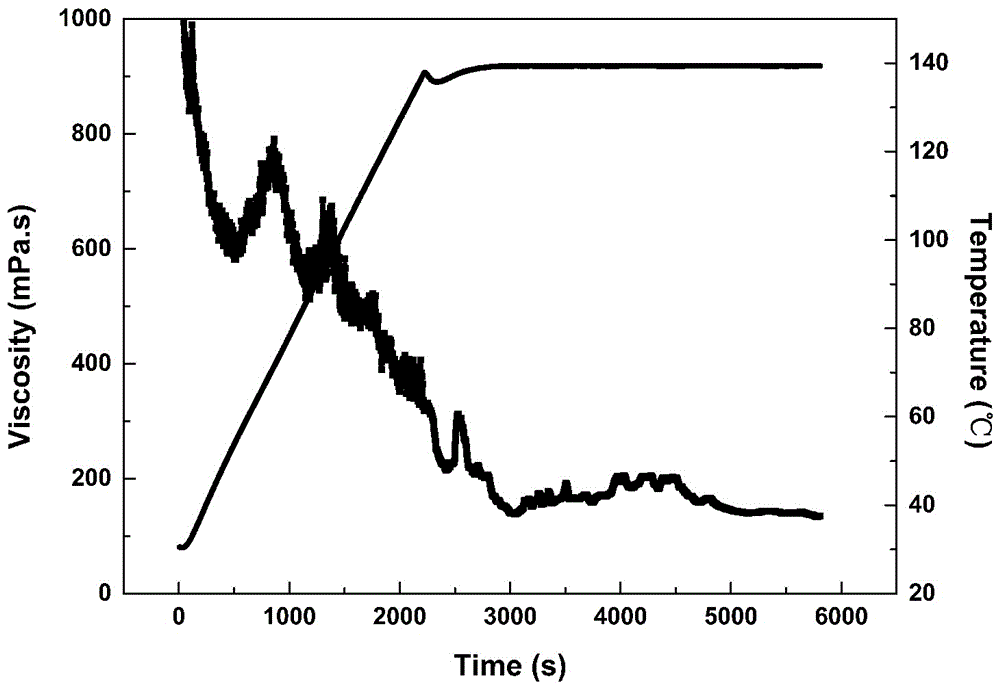

[0107] The apparent viscosity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com