Lignin-containing biomass fuel and preparing method thereof

A technology for biomass fuel and lignin is applied in the field of biomass fuel containing lignin and its preparation to achieve the effects of increasing friction, increasing calorific value, huge economic benefits and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

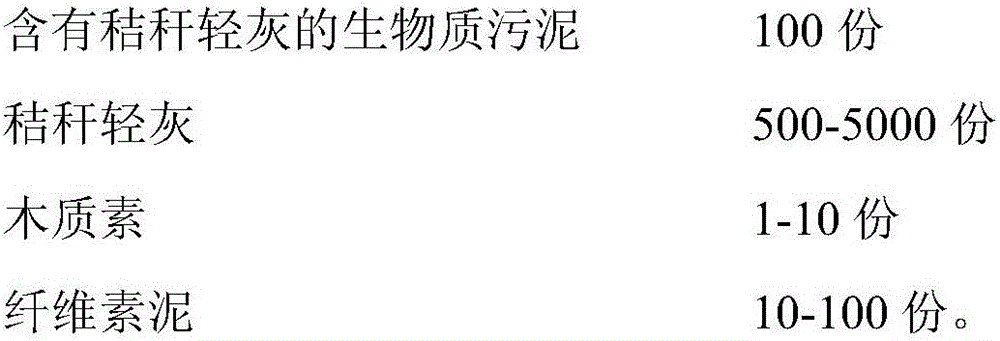

[0046] The composition of raw materials is as follows:

[0047]

[0048] Straw light ash is wheat straw.

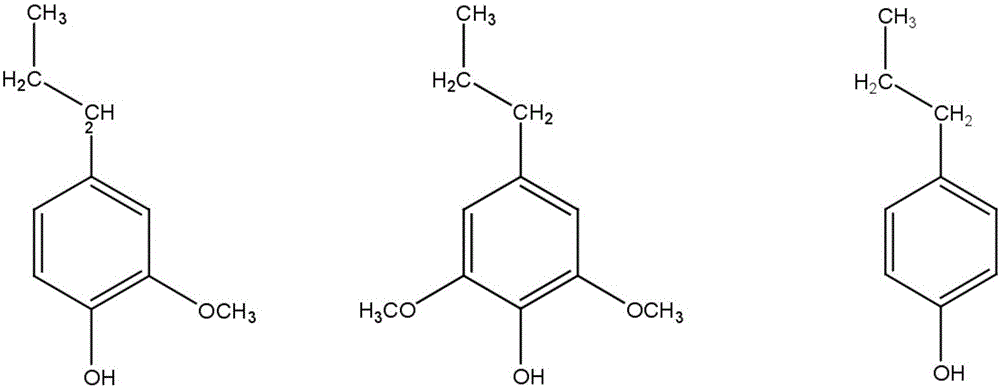

[0049] Lignin is solid: water content 3%, biochemical lignin content 85%, methylol 25%, phenolic hydroxyl 5%, solubility 30g / 100g water at normal temperature and pressure.

[0050] The cellulose content in the cellulose mud is 50wt%, the water content is 45wt%, and the ash content is 5wt%.

[0051] The preparation method is as follows:

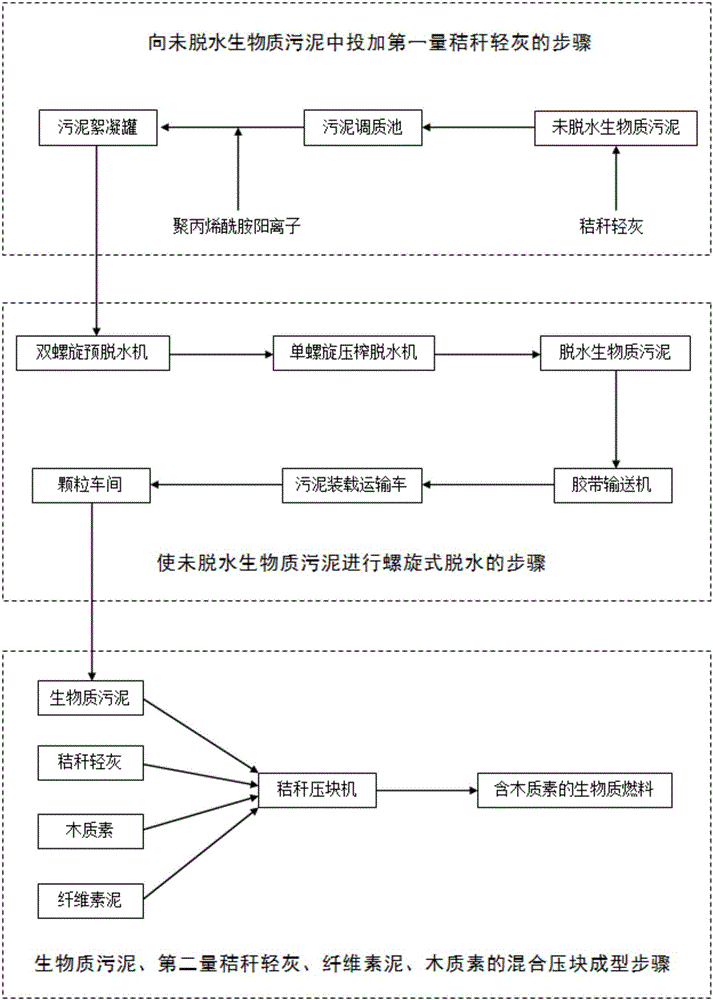

[0052] (1) adding straw light ash to the non-dehydrated biomass sludge and performing screw press dehydration to obtain dehydrated biomass sludge containing straw light ash;

[0053] (2) After mixing biomass sludge containing straw light ash, straw light ash, cellulose mud and lignin, briquetting is formed to obtain the final product.

[0054] Wherein, the water content of the undehydrated biomass sludge is 94wt%; the weight of straw light ash in the biomass sludge containing straw light ash is 160kg, calculated by the weight of eac...

Embodiment 2

[0056] The composition of raw materials is as follows:

[0057]

[0058] Straw light ash is wheat straw.

[0059] Lignin is solid: water content 3%, biochemical lignin content 85%, methylol 25%, phenolic hydroxyl 5%, solubility 30g / 100g water at normal temperature and pressure.

[0060] The cellulose content in the cellulose mud is 50wt%, the water content is 45wt%, and the ash content is 5wt%.

[0061] The preparation method is the same as in Example 1.

Embodiment 3

[0063] The composition of raw materials is as follows:

[0064]

[0065]

[0066] Straw light ash is wheat straw.

[0067] Lignin is solid: water content 3%, biochemical lignin content 85%, methylol 25%, phenolic hydroxyl 5%, solubility 30g / 100g water at normal temperature and pressure.

[0068] The cellulose content in the cellulose mud is 50wt%, the water content is 45wt%, and the ash content is 5wt%.

[0069] The preparation method is the same as in Example 1.

[0070] The specific operation steps are as follows:

[0071] Biomass fuel test base: Anhui Geyi Circular Economy Industrial Park Co., Ltd. pellet workshop;

[0072] Briquetting machine manufacturer Henan Derun Boiler Co., Ltd., model HMB series biomass molding machine.

[0073] 1. Sludge tempering tank: The construction location is on the first floor of the sludge dewatering machine room. The specification is 4m long x 4m wide x 3.5m high. There is a round hole with a diameter of 1.5m on the second floor r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com