Method for rapidly detecting lipid oxidation in refrigeration process of meat

A technology for lipid oxidation and meat products, which is applied in the direction of using electron paramagnetic resonance for analysis, etc., can solve the problems of influence of by-product detection results, large influence of sample color, long detection time, etc., and achieves short time consumption and low cost. , the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

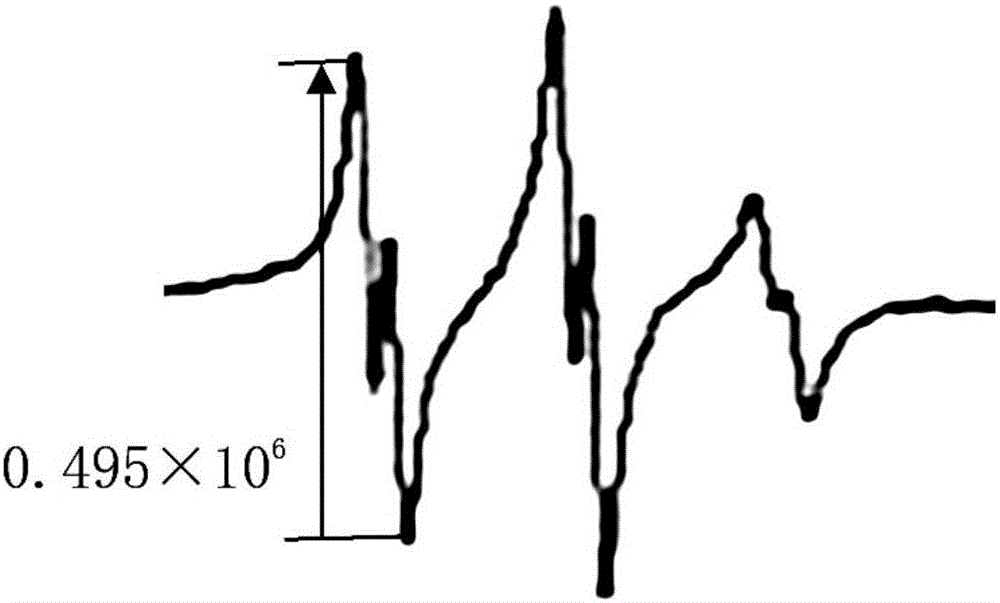

[0044] Take 0.5g of beef refrigerated for 3 days;

[0045]Add 1ml, 80mM POBN (a-(4-pyridyl-1-oxygen)-N-tert-butylnitroketone) solution to the meat and incubate for 20min;

[0046] Add 8ml of chloroform methanol mixed solution to the above system, the volume ratio is 1:1 and 6ml of deionized water;

[0047] Homogenize the above system;

[0048] Add 15ml of chloroform-methanol mixed solution to the above system again, the volume ratio of the two is 1:1;

[0049] Shake the above system on a vortex shaker for 2 minutes;

[0050] Then centrifuge the above system for 8min with 500g centrifugal force;

[0051] The chloroform layer was separated from the system with a separatory funnel:

[0052] Collect the chloroform solution through a sodium sulfate column;

[0053] Collect the above-mentioned chloroform solution after passing through the column and remove chloroform by rotary evaporation, and the rotary evaporation temperature is 50°C;

[0054] Collect the above-mentioned sam...

Embodiment 2

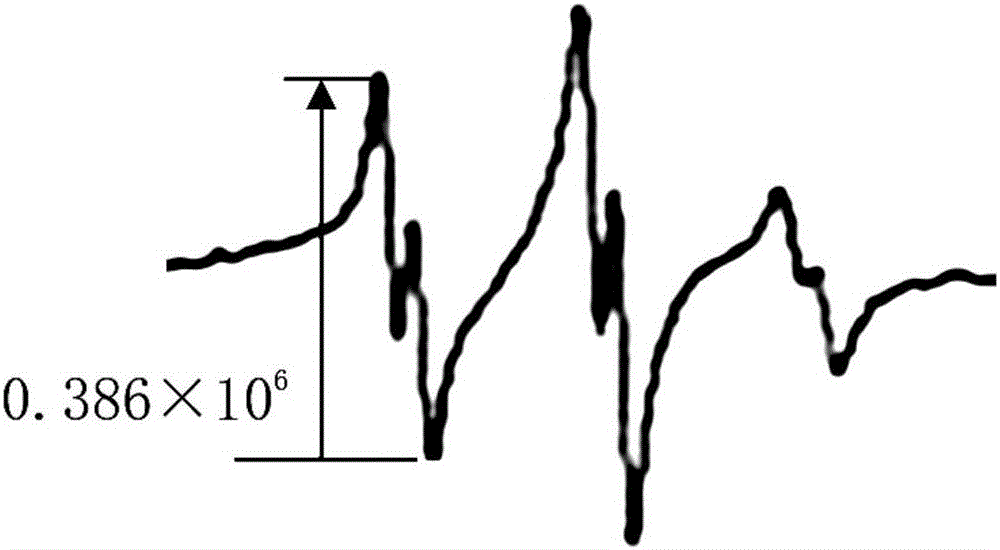

[0058] Take 1g of beef refrigerated for 5 days;

[0059] Add 1.5ml, 70mM POBN solution to the meat and incubate for 40min;

[0060] Add 6ml chloroform methanol mixed solution to the above system, the volume ratio is 4:1 and 5ml deionized water;

[0061] Homogenize the above system;

[0062] Add 18ml of chloroform-methanol mixed solution to the above system again, the volume ratio of the two is 4:1;

[0063] Oscillate the above system on a vortex shaker for 2.5 minutes;

[0064] Then centrifuge the above system for 10min with 800g centrifugal force;

[0065] The chloroform layer was separated from the system with a separatory funnel:

[0066] Collect the chloroform solution through a sodium sulfate column;

[0067] Collect the above-mentioned chloroform solution after passing through the column and remove chloroform by rotary evaporation, and the rotary evaporation temperature is 55 °C;

[0068] Collect the above-mentioned samples after rotary evaporation, and put them in...

Embodiment 3

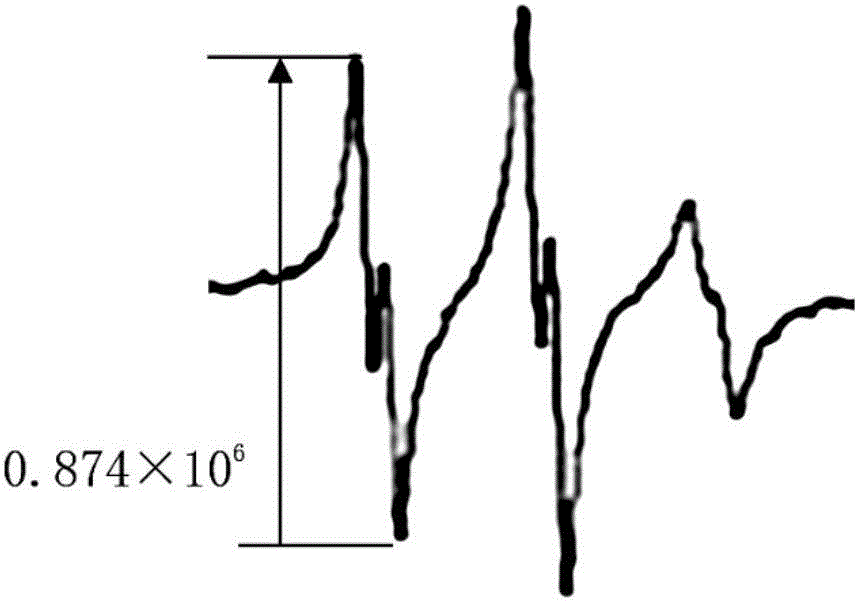

[0071] Take 1g of pork that has been refrigerated for 5 days;

[0072] Add 2ml, 50mM POBN solution to the meat and incubate for 30min;

[0073] Add 10ml chloroform methanol mixed solution to the above system, the volume ratio is 3:1 and 4ml deionized water;

[0074] Homogenize the above system;

[0075] Add 30ml of chloroform-methanol mixed solution to the above system again, the volume ratio of the two is 3:1;

[0076] Shake the above system on a vortex shaker for 3 minutes;

[0077] Then centrifuge the above system for 15min with 800g centrifugal force;

[0078] The chloroform layer was separated from the system with a separatory funnel:

[0079] Collect the chloroform solution through a sodium sulfate column;

[0080] Collect the above-mentioned chloroform solution after passing through the column and remove chloroform by rotary evaporation, and the rotary evaporation temperature is 45°C;

[0081] Collect the above-mentioned samples after rotary evaporation, and put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com