Modified carbon fiber reinforced PEK-C composite material

A technology of fiber reinforcement and composite materials, applied in the direction of coating, etc., can solve the problems of poor performance of composite materials, difficulty in high performance of carbon fiber, and low interface bonding strength, and achieve low interface bonding strength, increased activity, and improved wettability and adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

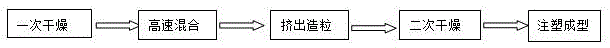

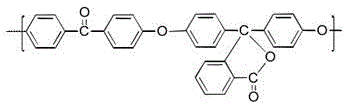

[0027] The PEK-C composite material of the present invention is composed of modified carbon fiber mixed with PEK-C, the matrix of the modified carbon fiber is chopped carbon fiber, and the modified carbon fiber is self-made by the laboratory. The carbon fiber raw material is firstly removed by acetone solution, and then dried in an oven. Finally, the carbon fiber is plasma-treated with a radio frequency inductively coupled plasma device. The drying temperature of the oven is 70°C, and the drying time is 1h; the output power of the radio frequency source is 300W.

[0028] The modified carbon fiber reinforced PEK-C composite material of this embodiment improves the surface activity of the carbon fiber, thereby improving the wettability and bonding force between the carbon fiber and the resin matrix, and also enhances the mechanical properties of the PEK-C composite material at the same time, making it It can be more widely applied to the fields of automobile, aerospace, processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com