Preparation method of transition metal disulfide quantum chip

A technology of transition metals and transition metal elements, which is applied in the field of preparation of transition metal dichalcogenide quantum chips, can solve the problems of complicated process, difficult to meet large-scale production, and difficult operation, so as to achieve simple and easy operation of the process and realize large-scale The effect of large-scale production and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

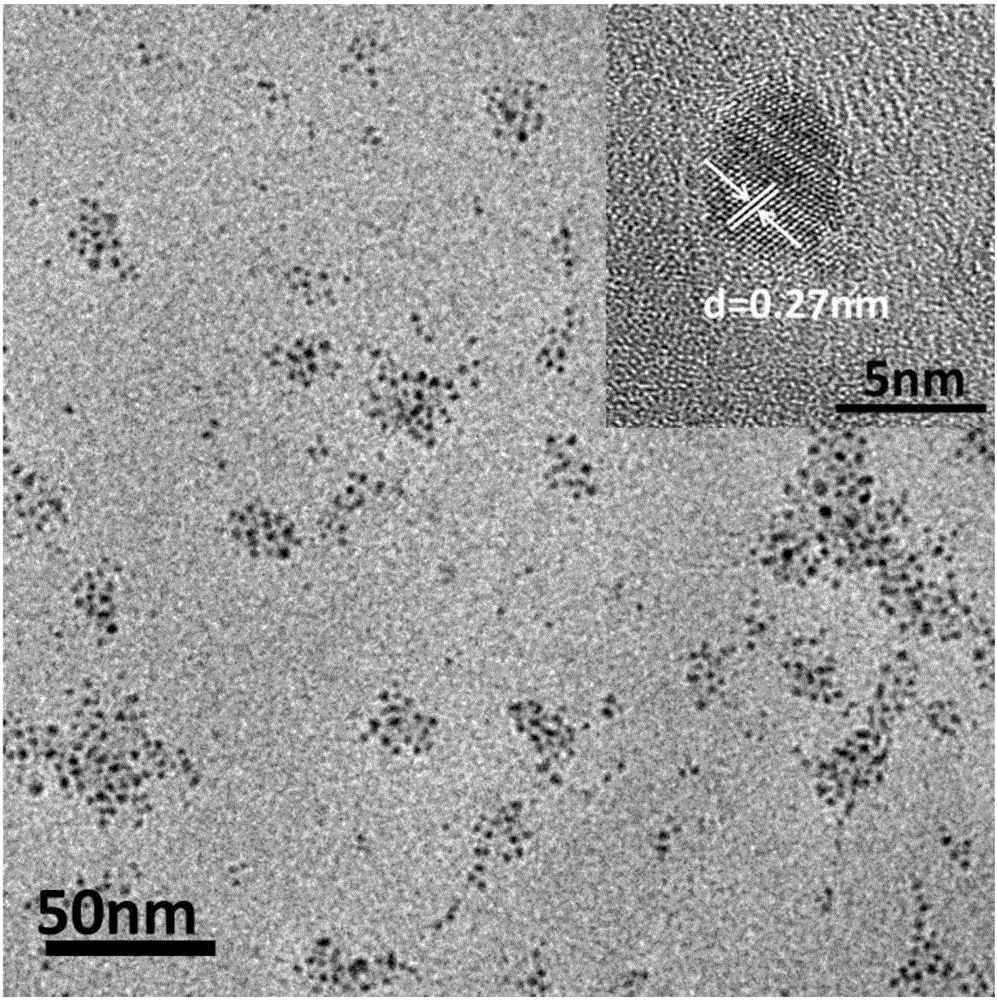

[0055] 1 g of MoS with an average size of 5 μm 2 , 1g of sodium chloride and 10g of agate balls with a diameter of 0.5mm are mixed, and ball milled for 0.5h. The agate balls were then separated, and the resulting sample was washed with water several times until the sodium chloride was completely washed out. After drying, N-methylpyrrolidone (NMP) was added, and ultrasonic power of 50 W was used for 120 h. The ultrasonic sample was first centrifuged at 500r / min for 120min, then vacuum filtered, and passed through a filter membrane with a pore size of 0.02μm to obtain MoS 2 NMP dispersion of quantum flakes.

[0056] The resulting MoS 2 The NMP dispersion of the quantum sheet was dried, and the obtained powder had a mass of 0.198g, and the calculated MoS 2 The final yield of quantum flakes was 19.8%.

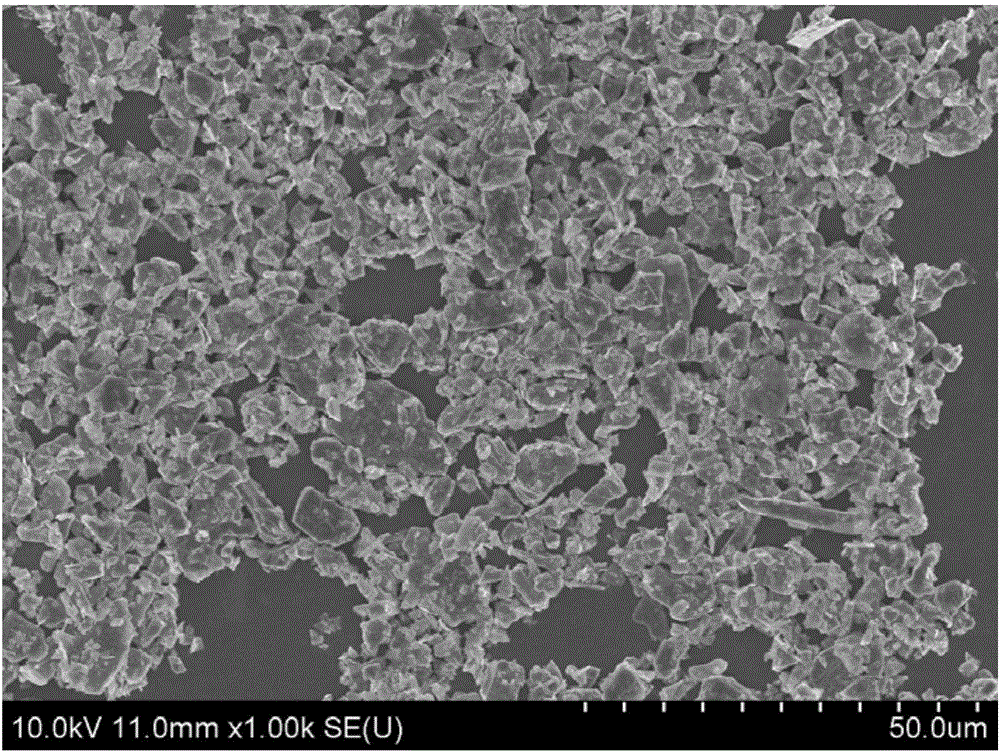

[0057] figure 1 MoS in Example 1 2 Scanning electron micrographs of raw materials. Depend on figure 1 It can be seen that the size thereof is 1-10 μm, and the average size...

Embodiment 2

[0061] 0.1 g of WS with an average size of 2 μm 2 , 10g of potassium sulfate and 10g of stainless steel balls with a diameter of 20mm were mixed, and ball milled for 120h. Then the stainless steel balls were separated, and the obtained samples were washed with water several times until the potassium sulfate was completely washed out. After drying, NMP was added, and ultrasonic power of 1000W was used for 0.5h. The ultrasonic sample is first centrifuged at 10000r / min for 1min, then vacuum filtered, and passed through a filter membrane with a pore size of 0.02μm to obtain WS 2 NMP dispersion of quantum flakes.

[0062] The resulting WS 2 The NMP dispersion of the quantum sheet is dried, and the powder mass obtained is 0.0211g, and the calculated WS 2 The final yield of quantum flakes was 21.1%.

[0063] Figure 4 WS in Example 2 2 Scanning electron micrographs of raw materials. Depend on Figure 4 It can be seen that the size thereof is 1-10 μm, and the average size is ...

Embodiment 3

[0065] 0.01 g of MoSe with an average size of 100 μm 2, 0.1g of calcium carbonate and 5g of zirconia balls with a diameter of 6mm were mixed, and ball milled for 20 hours. Then the zirconia balls were separated, and the obtained sample was washed with hydrochloric acid for many times until the calcium carbonate was completely washed away, and then washed with water for many times to completely wash away the residual hydrochloric acid. After drying, dimethyl sulfoxide (DMSO) was added and ultrasonicated at 200 W for 5 h. The ultrasonic sample was first centrifuged at 5000r / min for 20min, then vacuum filtered, and passed through a filter membrane with a pore size of 0.02μm to obtain MoSe 2 DMSO dispersion of quantum flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com