Sodium-alginate-based hydrogel and preparation method thereof

A technology for sodium alginate and sodium alginate oxidation, applied in the field of polymer materials, can solve problems such as loss of gel properties and easy dissolution, and achieve the effects of good healing ability, easy availability of raw materials, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

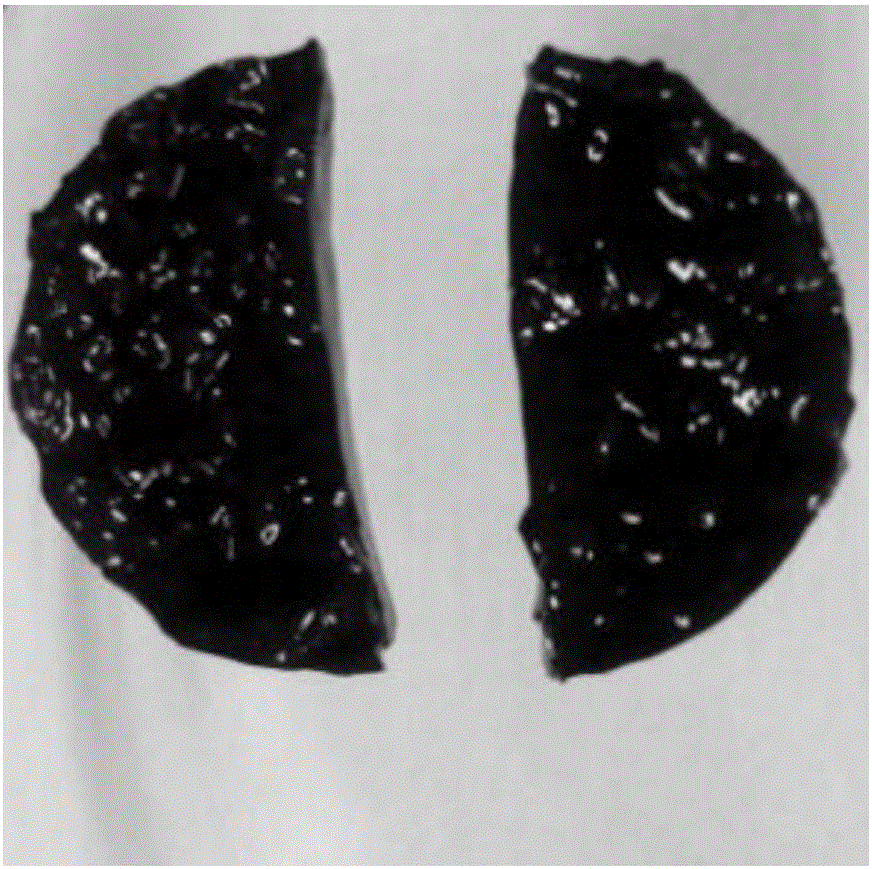

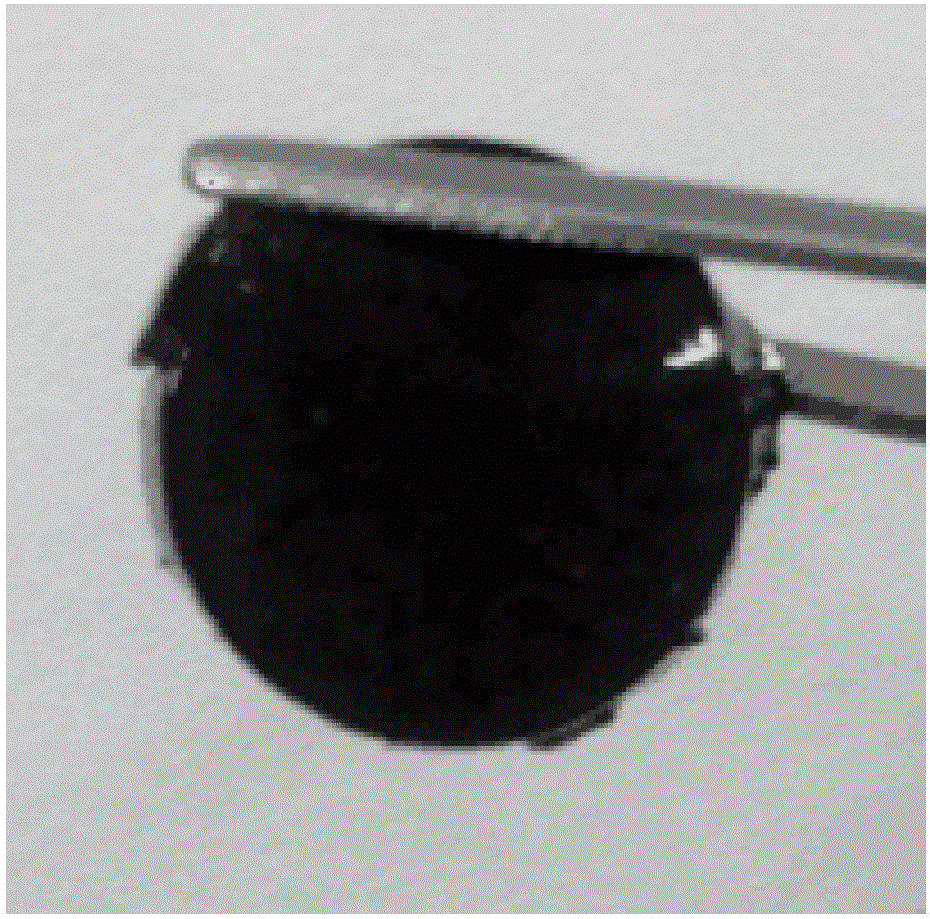

[0041] The specific steps for preparing sodium alginate-based hydrogel are as follows:

[0042] 1) Preparation of oxidized sodium alginate: Add 5.001g sodium alginate to 25mL n-propanol to form a sodium alginate-n-propanol suspension with a concentration of 200g / L, and add 25ml 1.0mol / L peroxide in turn Hydrogen solution and 4ml 6.0mol / L acetic acid solution were stirred and reacted for 2h at 8°C in the dark, 5ml ethylene glycol was added to react for 30min, then 0.7g NaCl was added, and the reaction was terminated after 30min. The reaction product was dialyzed in deionized water with a dialysis bag, and the water was changed twice a day. After dialysis for 2 days, it was freeze-dried to obtain oxidized sodium alginate with an oxidation degree of 73.81%.

[0043] 2) Preparation of sodium alginate with amino groups: 1.0002g (0.005mol) of sodium alginate in 100mL deionized water was prepared into a sodium alginate solution with a concentration of 10g / L, and the sodium alginate soluti...

Embodiment 2

[0049] The specific steps for preparing sodium alginate-based hydrogel are as follows:

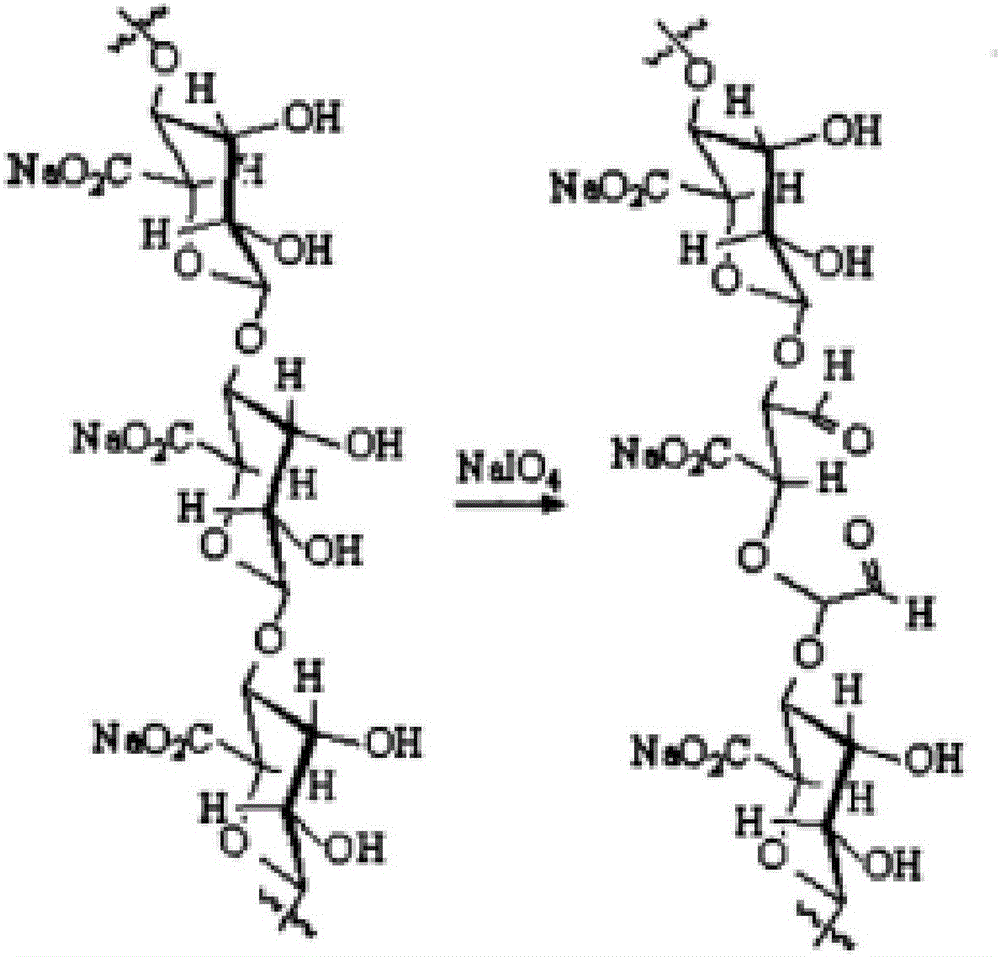

[0050] 1) Preparation of oxidized sodium alginate: add 2.5003g sodium alginate to 25mL n-propanol to prepare a 100g / L sodium alginate-n-propanol suspension, and add 25ml 0.3mol / L high iodine sequentially Sodium aqueous solution and 12ml 1.0mol / L sulfuric acid solution were stirred and reacted at 15°C in the dark for 6h, 5ml ethylene glycol was added to react for 30min, then 0.7g NaCl was added, and the reaction was terminated after 30min. The reaction product was dialyzed in deionized water with a dialysis bag, the water was changed twice a day, and lyophilized after 2 days of dialysis to obtain oxidized sodium alginate with an oxidation degree of 53.82%;

[0051] 2) Preparation of sodium alginate with amino groups: 0.5002g (0.0025mol) of sodium alginate in 100mL deionized water, mixed with a concentration of 50g / L sodium alginate solution, adjust the sodium alginate solution with 1mol / L dilute...

Embodiment 3

[0055] The specific steps for preparing sodium alginate-based hydrogel are as follows:

[0056] 1) Preparation of oxidized sodium alginate: add 1.0000g sodium alginate to 25mL n-propanol to prepare a 4% (w / v) sodium alginate-n-propanol suspension, and add 25ml 0.1mol / L After sodium periodate aqueous solution and 6ml 4.0mol / L dilute hydrochloric acid solution were stirred and reacted at 25°C in the dark for 12h, 5ml ethylene glycol was added to react for 30min, then 0.7g NaCl was added, and the reaction was terminated after 30min. The reaction product was dialyzed in deionized water with a dialysis bag, the water was changed twice a day, and lyophilized after 2 days of dialysis to obtain oxidized sodium alginate with an oxidation degree of 36.64%;

[0057] 2) Preparation of sodium alginate with amino groups: Dissolve 2.0001 g of sodium alginate (0.010mol) in 100mL of deionized water, make a 2% (w / v) sodium alginate solution, adjust with 1mol / L dilute hydrochloric acid Sodium algina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com