Low smell, low emission, halogen-free, and flame retardant PA6/PP alloy and preparation method thereof

A low-emission, low-odor technology, applied in the field of polymer materials, can solve problems such as unpleasant smell, car interior parts, and large odor, and achieve low emission, low-odor characteristics, and low-odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

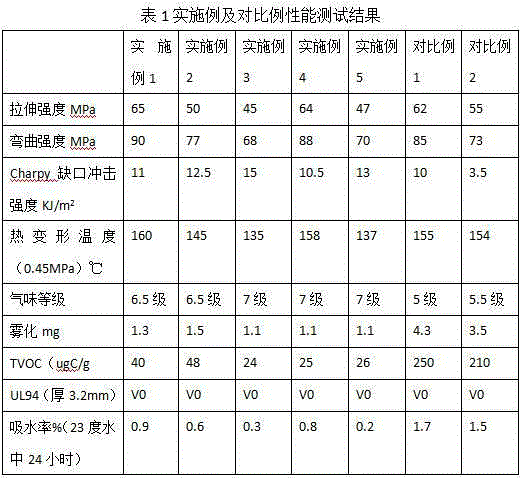

Examples

Embodiment 1

[0021] (1) Preparation of hydrophobic odor adsorption masterbatch: 50 parts of polypropylene, 10 parts of hydrophobic diatomaceous earth, 10 parts of hydrophobic activated carbon, 10 parts of needle-shaped zeolite molecular sieve, 10 parts of zinc ricinoleate, polymer quaternary ammonium 10 parts of salt-grafted nano silica, 5,7-bis-(2,2-dimethylethyl)-3-(3,4-dimethylphenyl)-2-3hydro-benzofuran 0.1 part of ketone, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.5 part of lubricant zinc stearate were added to a high-speed mixer and mixed evenly, and then extruded and granulated in a twin-screw extruder to obtain hydrophobic odor adsorption masterbatch;

[0022] (2) Preparation of low-odor, low-emission, halogen-free flame-retardant PA6 / PP alloy: Weigh and dry the following components by mass: 75 parts of nylon 6, 10 parts of polypropylene, 10 parts of red phosphorus, maleic anhydride 3 parts of grafted polypropylene, 2 parts of hydrophobic odor-absorbing maste...

Embodiment 2

[0024] (1) Preparation of hydrophobic odor adsorption masterbatch: 40 parts of polypropylene, 20 parts of hydrophobic diatomaceous earth, 10 parts of hydrophobic activated carbon, 10 parts of needle-shaped zeolite molecular sieve, 10 parts of zinc ricinoleate, polymer quaternary ammonium 10 parts of salt-grafted nano silica, 5,7-bis-(2,2-dimethylethyl)-3-(3,4-dimethylphenyl)-2-3hydro-benzofuran 0.1 part of ketone, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.5 part of lubricant zinc stearate were added to a high-speed mixer and mixed evenly, and then extruded and granulated in a twin-screw extruder to obtain hydrophobic odor adsorption masterbatch;

[0025] (2) Preparation of low-odor, low-emission, halogen-free flame-retardant PA6 / PP alloy: Weigh and dry the following components by mass: 35 parts of nylon 6, 30 parts of polypropylene, 30 parts of magnesium hydroxide, Malay 5 parts of acid anhydride grafted polypropylene, 0.5 part of hydrophobic odor-absor...

Embodiment 3

[0027] (1) Preparation of hydrophobic odor-absorbing masterbatch: 75 parts of polypropylene, 10 parts of hydrophobic diatomite, 5 parts of needle-shaped zeolite molecular sieve, 5 parts of zinc ricinoleate, and grafted nano-dioxide with polymer quaternary ammonium salt 5 parts of silicon, 0.1 part of 5,7-bis-(2,2-dimethylethyl)-3-(3,4-dimethylphenyl)-2-3hydro-benzofuranone, antioxidant Add 0.2 part of agent 1010, 0.2 part of antioxidant 168, and 0.5 part of lubricant zinc stearate into a high-speed mixer and mix evenly, then extrude and granulate in a twin-screw extruder to obtain hydrophobic odor adsorption masterbatch;

[0028] (2) Preparation of low-odor, low-emission, halogen-free flame-retardant PA6 / PP alloy: Weigh and dry the following components by mass: 10 parts of nylon 6, 60 parts of polypropylene, 22 parts of melamine polyphosphate, horse 1 part of toric anhydride grafted polypropylene, 5 parts of hydrophobic odor-absorbing masterbatch, 0.3 part of antioxidant 1010,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com