Lactobacillus fermentum capable of degrading arginine and urea simultaneously

A technology for fermenting lactobacillus and strains, applied in the field of microorganisms, can solve problems such as the research on food safety effect of non-lactobacillus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the degradation situation of lactic acid bacteria of the present invention to arginine, urea

[0037] According to the detection results of arginine and urea in the fermented grains, the addition amount of arginine in the metabolic experiment was designed to be 300 mg L -1 (Sorghum juice medium itself contains a certain amount of arginine, add 300mg L -1 The final total arginine content is about 690mg / L, which is close to the arginine content in real wine grains), and the added amount of urea is 200mg L -1. Sorghum juice was used to ferment arginine and urea metabolism experiments on experimental strains L.diolivorans2-10, L.buchneri N5, L.casei X1, Lpontis JSB7, P.acidilactici JJB1, Lfermentum JSA30 and L.plantarum JD19.

[0038] Experimental and control group settings:

[0039] Blank 1: Sorghum juice medium was inoculated at 2% inoculation volume, without adding arginine and urea;

[0040] Experimental group 1: add 300mg L -1 The sorghum juice cultu...

Embodiment 2

[0053] L.plantarum JD19 was deposited in the General Microorganism Center of China Microbiological Culture Collection Management Committee on June 28, 2016. The preservation number is CGMCC NO.12717, and the preservation address is No. 3, Courtyard No. 1, Beichen West Road, Chaoyang District, Beijing. Embodiment 2: Physiological and biochemical characteristics of lactic acid bacteria

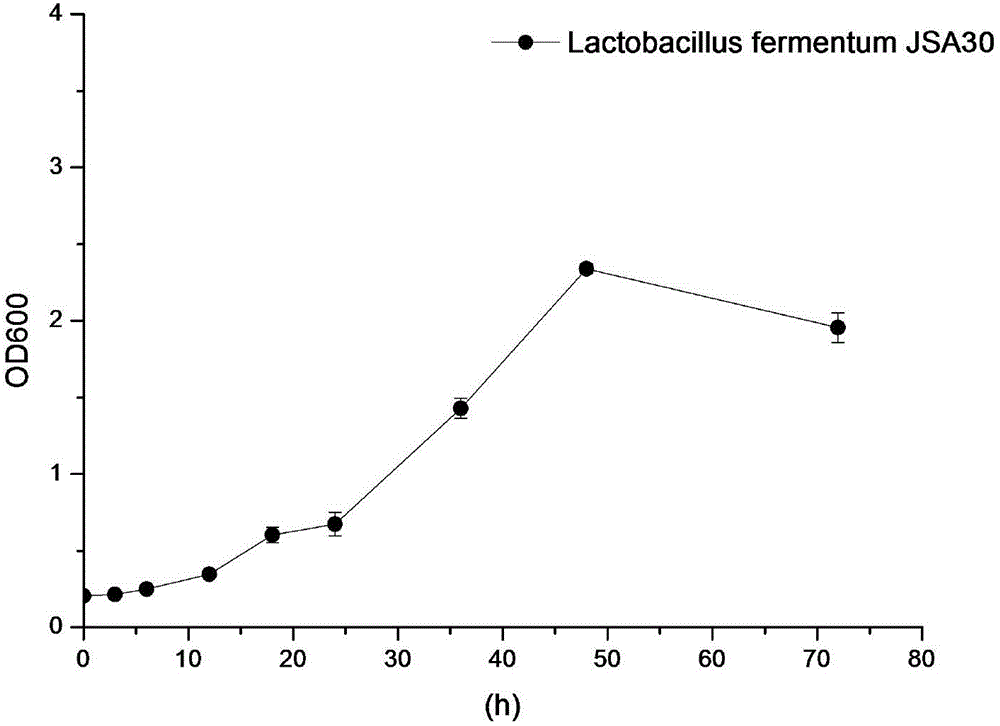

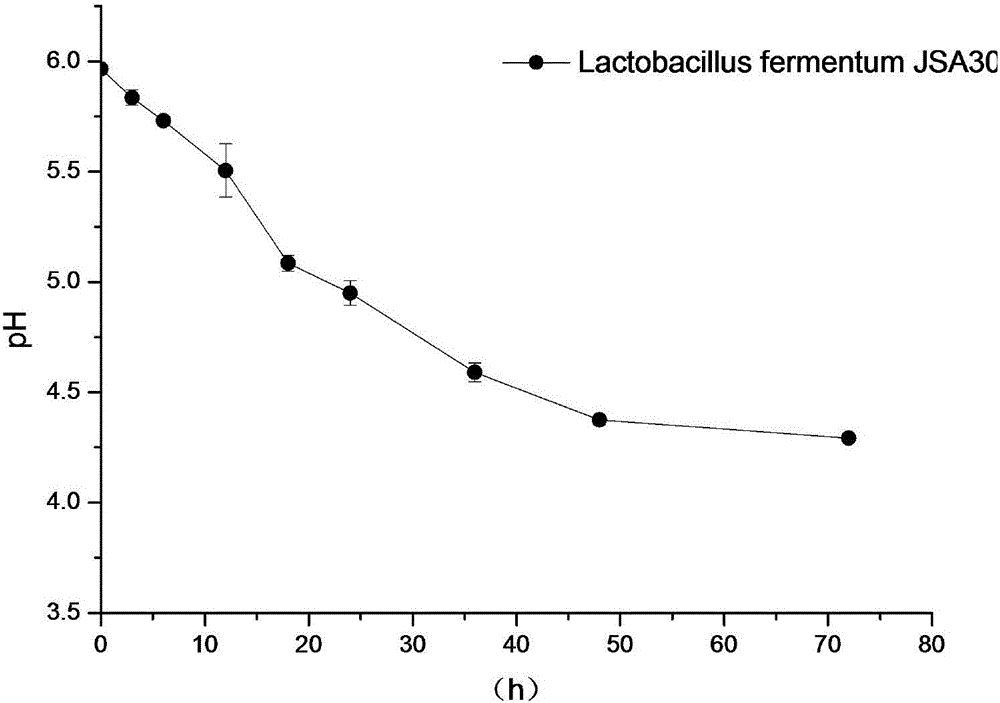

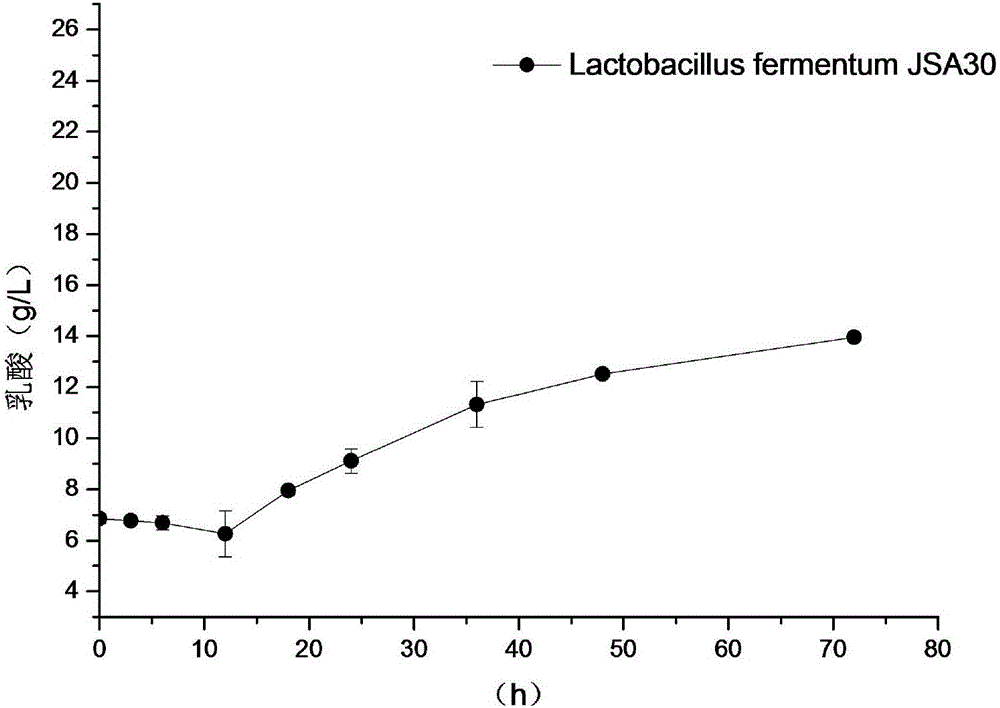

[0054] Lactobacillus fermentum L.fermentum JSA30 was inoculated in MRS medium, and after anaerobic fermentation at 30°C for 2 days, the two strains of lactic acid bacteria entered the stationary phase. Such as figure 1 As shown, after 2 days of fermentation, the biomass OD of L.fermentum JSA30 600 Up to 2.4.

[0055] MRS liquid medium: peptone 10.0g L -1 , beef extract 10.0g·L -1 , yeast extract 5.0g·L -1 , diammonium hydrogen citrate 2.0g·L -1 , glucose 20.0g·L -1 , Tween 801.0mL·L -1 Sodium acetate 5.0g·L -1 , dipotassium hydrogen phosphate 2.0g·L -1 , magnesium sulfate 0.58g L -1 ,...

Embodiment 3

[0060] Embodiment 3: the application of bacterial strain

[0061] Preparation of solid-state fermentation medium: Weigh 250g of sorghum, add 350mL of distilled water, and soak in an incubator at 70-80°C for 24 hours. Drain the water, weigh 500g of sorghum in a vacuum bag, and add 25mL of distilled water. Sterilize at 121°C for 20 minutes. Enzyme saccharification 1d.

[0062] Control group: Inoculate 10wt% high-temperature Daqu in a solid-state fermentation medium, and ferment for 6 days in a constant temperature incubator at 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com