Al2O3 modified array TiO2 nanowire and method for photoelectrocatalysis water decomposition hydrogen production

A technology of nanowires and arrays, applied in the field of photocatalysis, to achieve large surface area, improve photocatalytic performance, and increase the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

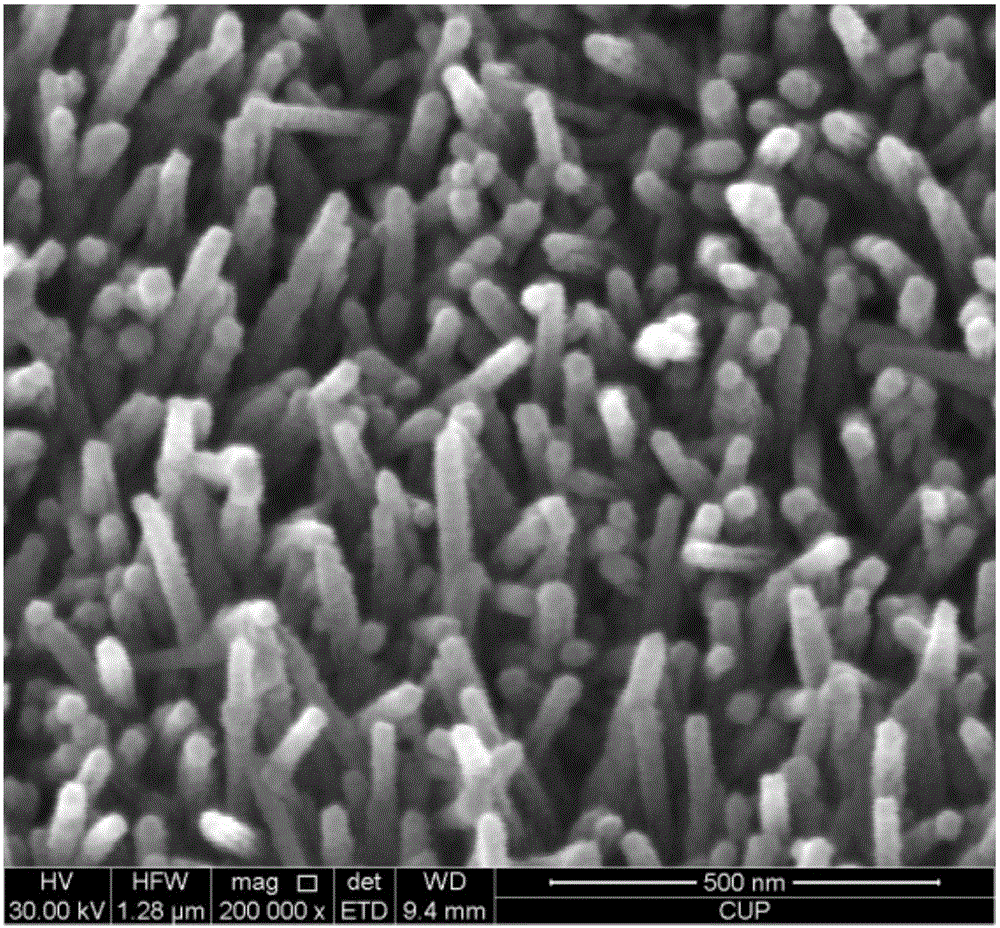

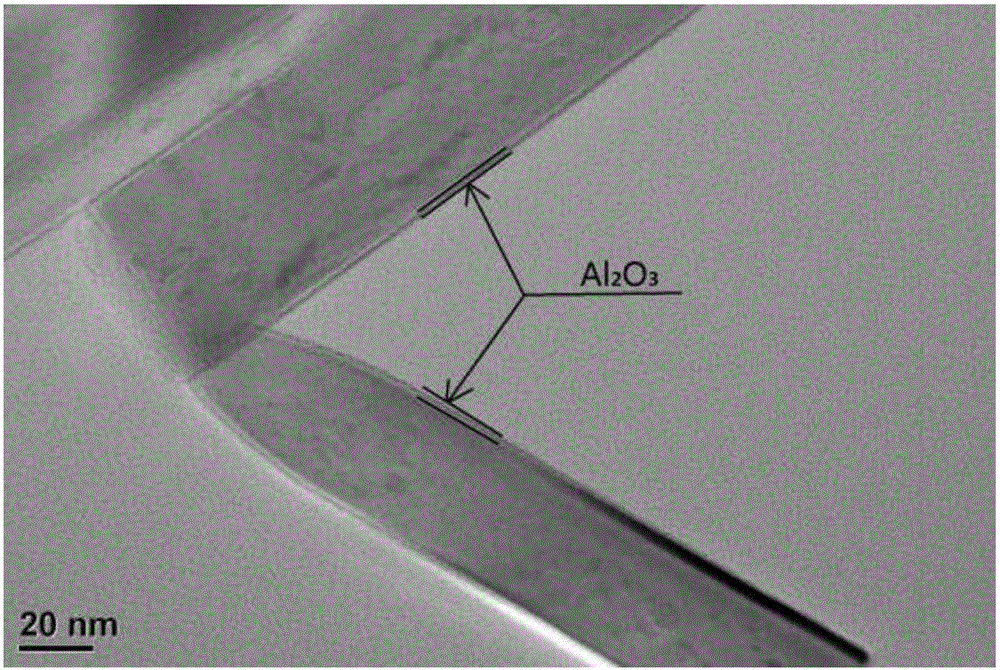

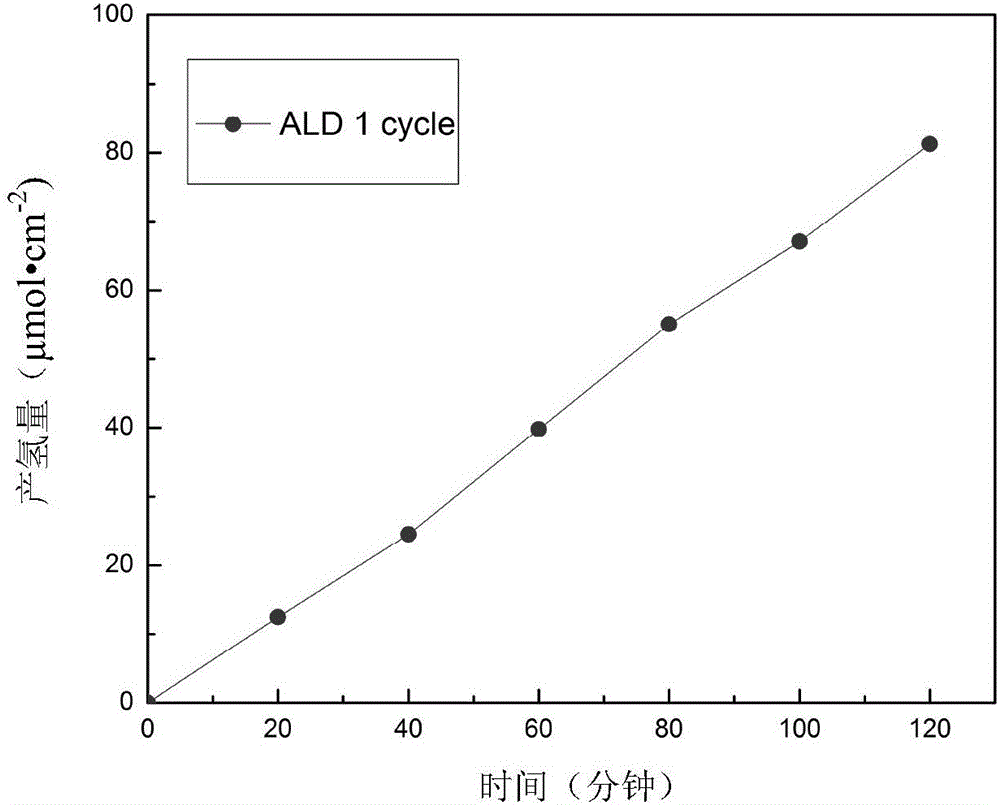

[0057] This embodiment provides an Al 2 o 3 Modified Array TiO 2 Nanowire photocatalyst, its preparation method specifically comprises the following steps:

[0058] The carbon cloth was ultrasonically cleaned in acetone, distilled water, and absolute ethanol in sequence. Prepare a n-hexane solution of titanium tetrachloride with a concentration of 0.05mol / L, soak the cleaned carbon cloth in it, and let it stand for 10 hours; take out the carbon cloth and put it in a tube furnace, and raise the temperature from 30°C at 4°C / min To 500°C, keep the temperature at 500°C for 30 minutes, and make a carbon cloth with a good seed layer. In a 200ml polytetrafluoroethylene reaction kettle, add toluene, tetrabutyl titanate, concentrated hydrochloric acid (that is, concentrated hydrochloric acid with a mass concentration of 37%), and titanium tetrachloride dropwise in sequence, and stir well, wherein toluene, tetrabutyl titanate The volume ratio of butyl ester, concentrated hydrochlori...

Embodiment 2

[0061] This embodiment provides an Al 2 o 3 Modified Array TiO 2 Nanowire photocatalyst, its preparation method specifically comprises the following steps:

[0062] The carbon cloth was ultrasonically cleaned in acetone, distilled water, and absolute ethanol in sequence. Prepare a n-hexane solution of titanium tetrachloride with a concentration of 0.05mol / L, soak the cleaned carbon cloth in it, and let it stand for 10 hours; take out the carbon cloth and put it in a tube furnace, and raise the temperature from 30°C at 4°C / min To 500°C, keep the temperature at 500°C for 30 minutes, and make a carbon cloth with a good seed layer. In a 200ml polytetrafluoroethylene reaction kettle, add toluene, tetrabutyl titanate, concentrated hydrochloric acid (that is, concentrated hydrochloric acid with a mass concentration of 37%), and titanium tetrachloride dropwise in sequence, and stir well, wherein toluene, tetrabutyl titanate The volume ratio of butyl ester, concentrated hydrochlori...

Embodiment 3

[0066] This embodiment provides an Al 2 o 3 Modified Array TiO 2 Nanowire photocatalyst, its preparation method specifically comprises the following steps:

[0067] The carbon cloth was ultrasonically cleaned in acetone, distilled water, and absolute ethanol in sequence. Prepare a n-hexane solution of titanium tetrachloride with a concentration of 0.01mol / L, soak the cleaned carbon cloth in it, and let it stand for 10 hours; take out the carbon cloth and put it in a tube furnace, and raise the temperature from 30°C at 4°C / min To 500°C, keep the temperature at 500°C for 30 minutes, and make a carbon cloth with a good seed layer. In a 200ml polytetrafluoroethylene reaction kettle, add toluene, tetrabutyl titanate, concentrated hydrochloric acid (that is, concentrated hydrochloric acid with a mass concentration of 37%), and titanium tetrachloride dropwise in sequence, and stir well, wherein toluene, tetrabutyl titanate The volume ratio of butyl ester, concentrated hydrochlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com